Fatty group end-amino polyether production method and special catalyzer preparation method

A technology of amino-terminated polyether and production method, which is applied in the field of chemical compounds, can solve the problems of many reaction by-products, high investment cost, and easy pollution of the environment, and achieve the effects of high reaction conversion rate, low investment cost, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

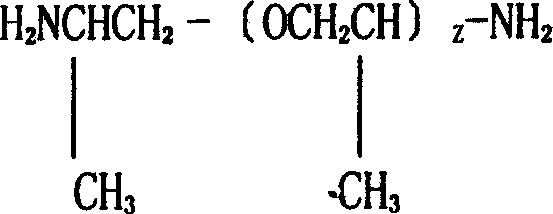

Method used

Image

Examples

Embodiment 1

[0034]A kind of preparation method of special-purpose catalyst in the production method of aliphatic amino-terminated polyether, this catalyst is special-purpose skeleton nickel catalyst, and it comprises the following steps:

[0035] a) Take 75.0g of sodium hydroxide, add 300g of distilled water, and stir at 50-80°C to form a sodium hydroxide solution, and 60.0g of nickel metal accounts for about 45%, metal aluminum accounts for about 50%, and metal chromium accounts for about 5%. Customize the alloy, slowly add it to the sodium hydroxide solution while stirring, and then stir at a constant temperature of 70-80°C for 2.0 hours to fully react;

[0036] b) washing the prepared alloy with distilled water until neutral, with a pH value of 7 to 8;

[0037] c) washing the alloy twice with absolute ethanol to replace the moisture in the alloy;

[0038] d) Dip the alloy in absolute ethanol and seal it for later use.

Embodiment 2

[0040] A kind of production method of the aliphatic amino-terminated polyether of the present invention, it adopts gap kettle type reaction process catalytic ammoniation to synthesize aliphatic amino-terminated polyether, it comprises the following steps:

[0041] A) select special skeleton nickel catalyst, its main component is metal nickel, metal aluminum and metal chromium, the mass ratio of its each component is: metal nickel accounts for about 75%, metal aluminum accounts for about 20%, metal chromium accounts for about 5% %; The catalyst is sealed for subsequent use;

[0042] B) In the autoclave, the catalyst described in step A) is used to carry out the hydroammination reaction, and the addition amount of the catalyst is 45g; the raw material polyether polyol adopts 5000 molecular weight, trifunctional polyoxypropylene ether, and its addition The amount is 500g; the amount of liquid ammonia added is 3 to 20 times the number of hydroxyl moles in polyoxypropylene ether, w...

Embodiment 3

[0046] Another kind of production method of aliphatic amino-terminated polyether of the present invention, it adopts batch reaction process catalytic ammoniation to synthesize aliphatic amino-terminated polyether, it comprises the following steps:

[0047] A) select special skeleton nickel catalyst, its main component is metal nickel, metal aluminum and other metal components, the mass ratio of each component of it is: metal nickel accounts for about 75%, metal aluminum accounts for about 20%, metal chromium accounts for about 5%; The catalyst is sealed for subsequent use;

[0048] B) In the autoclave, the catalyst described in step A) is used to carry out the hydroammination reaction, and the addition amount of the catalyst is 40g; the raw material polyether polyol adopts 2000 molecular weight, difunctional polyoxypropylene ether, and its addition The amount is 500g; the amount of liquid ammonia added is 3 to 20 times the number of hydroxyl moles in polyoxypropylene ether, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com