Liquid fuel and producing method thereof

A liquid fuel and fuel technology, applied in the direction of liquid carbon-containing fuel, fuel, petroleum industry, etc., can solve the problems of diesel stove noise, environmental pollution, oily smoke, etc., achieve stable flame, high calorific value, and increase calorific value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

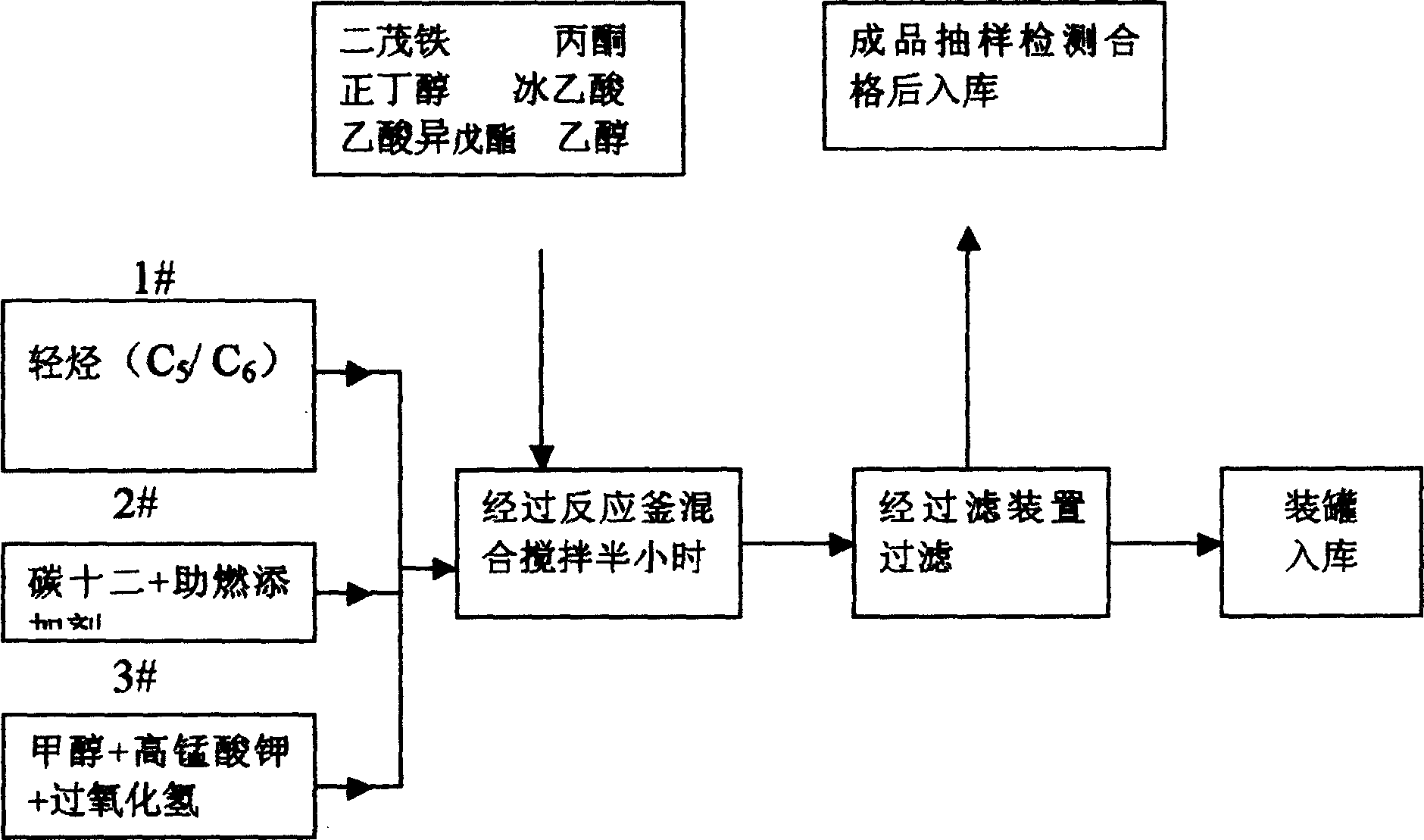

Method used

Image

Examples

Embodiment 1

[0037] Its composition proportion of liquid fuel of the present invention is as follows (weight part)

[0038] Light hydrocarbons (C 5 / C 6 ) 58 Methanol (90%) 9

[0039] Modified carbon twelve (C 12 ) 22 Potassium permanganate (industrial pure) 0.004

[0040] Hydrogen peroxide (industrial pure) 0.005 Ferrocene (industrial pure) 0.004

[0041] Acetone (industrial pure) 0.7 n-Butanol (industrial pure) 0.06

[0042] Glacial acetic acid (industrial pure) 0.04 Isoamyl acetate (industrial pure) 0.006

[0043] Ethanol (90%) (technical pure) 10.2

[0044] In the above proportions, the oxidant potassium permanganate (solid) needs to be dissolved in hot water (90°C) before synthesis, and is prepared according to the following proportions (% by weight): 10% potassium permanganate, hot water (90°C )90%.

[0045] In the above ratio, modified C 12 for C 12 It is compounded with super-combustible additive, (super-combustible additive is produced by Kangfu Chemical Machinery Resear...

Embodiment 2

[0059] Its composition proportion of liquid fuel of the present invention is as follows (weight part)

[0060] Light hydrocarbons (C 5 / C 6 ) 63 modified carbon twelve (C 12 ) twenty two

[0061] Ferrocene (industrial pure) 0.003 Acetone (industrial pure) 0.6

[0062] Butanol (industrial pure) 0.07 Glacial acetic acid (industrial pure) 0.03

[0063] Isoamyl acetate (industrial pure) 0.005 Ethanol (90%) (industrial pure) 14.3

[0064] In the above ratio, modified C 12 for C 12 It is compounded with super-combustible additive, (super-combustible additive is produced by Kangfu Chemical Machinery Research Institute, Huangshi City, Hubei Province), prepared according to the following ratio (% by weight):

[0065]Carbon twelve (C 12 ) 99.8%, super combustion additive 0.2%.

[0066] After testing by the Ministry of Aeronautics and Astronautics 42, the highest calorific value reaches more than 10,000 kcal. After testing by Hubei Provincial Bureau of Technical Supervision ...

Embodiment 3

[0077] Its composition proportion of liquid fuel of the present invention is as follows (weight part)

[0078] Light hydrocarbons (C 5 / C 6 ) 64 Methanol (90%) 5

[0079] Modified carbon twelve (C 12 ) 20 Potassium permanganate (industrial pure) 0.003

[0080] Hydrogen peroxide (industrial pure) 0.004 Ferrocene (industrial pure) 0.003

[0081] Acetone (industrial pure) 0.6 n-Butanol (industrial pure) 0.07

[0082] Ethanol (90%) (industrial pure) 10.3

[0083] In the above proportioning, the oxidant potassium permanganate (solid) needs to be dissolved with hot water (90°C) before synthesis, and is prepared according to the following proportioning (% by weight): potassium permanganate 10%, hot water (90°C )90%.

[0084] In the above ratio, modified C 12 for C 12 It is compounded with super-combustible additive, (super-combustible additive is produced by Kangfu Chemical Machinery Research Institute, Huangshi City, Hubei Province), prepared according to the following rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com