Method for preparing nano zinc oxide in monodisperse, with no agglomeration and strong ultraviolet absorption

A nano-zinc oxide and external absorption technology, which is applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of easy agglomeration and uneven particle size of nano-zinc oxide, and achieve uniform particle size distribution, cheap reaction raw materials, and low reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] ①Preparation of reaction solution: Dissolve 0.0005mol of zinc nitrate and 0.00075mol of hexamethylenetetraammonia in 100ml of methanol solution, then add 0.5g of PVP, stir until the solution is clear, and then prepare a reaction solution.

[0024] ②Synthesis of nano-zinc oxide: Pour the above-mentioned growth reaction solution of zinc oxide nanocrystals into a tetrafluoroethylene reactor, seal it, heat up to 100°C, and react for 3 hours. After the reaction, naturally cool to room temperature and take out the sample Centrifugal separation, natural drying after repeated washing can obtain nano-zinc oxide crystals.

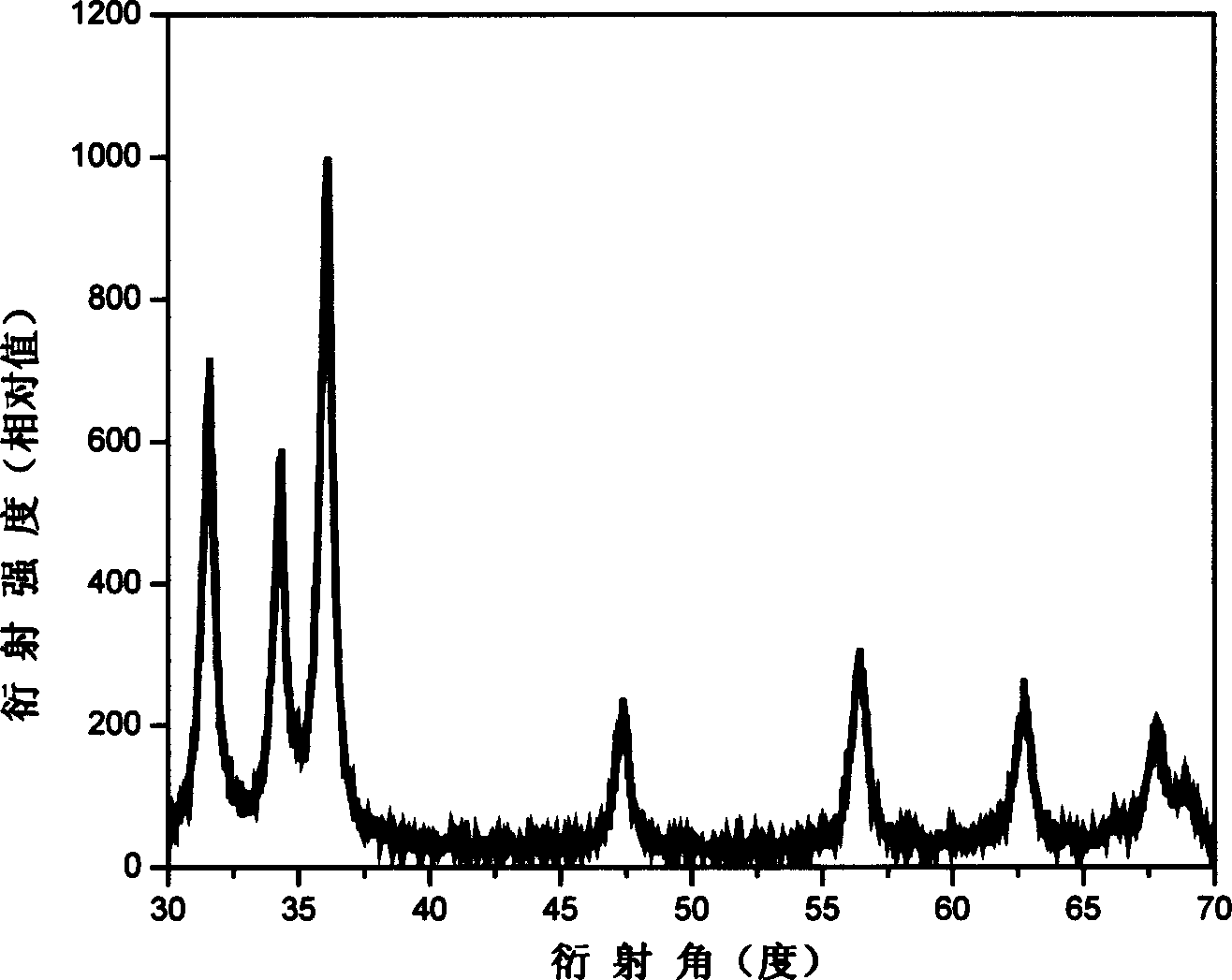

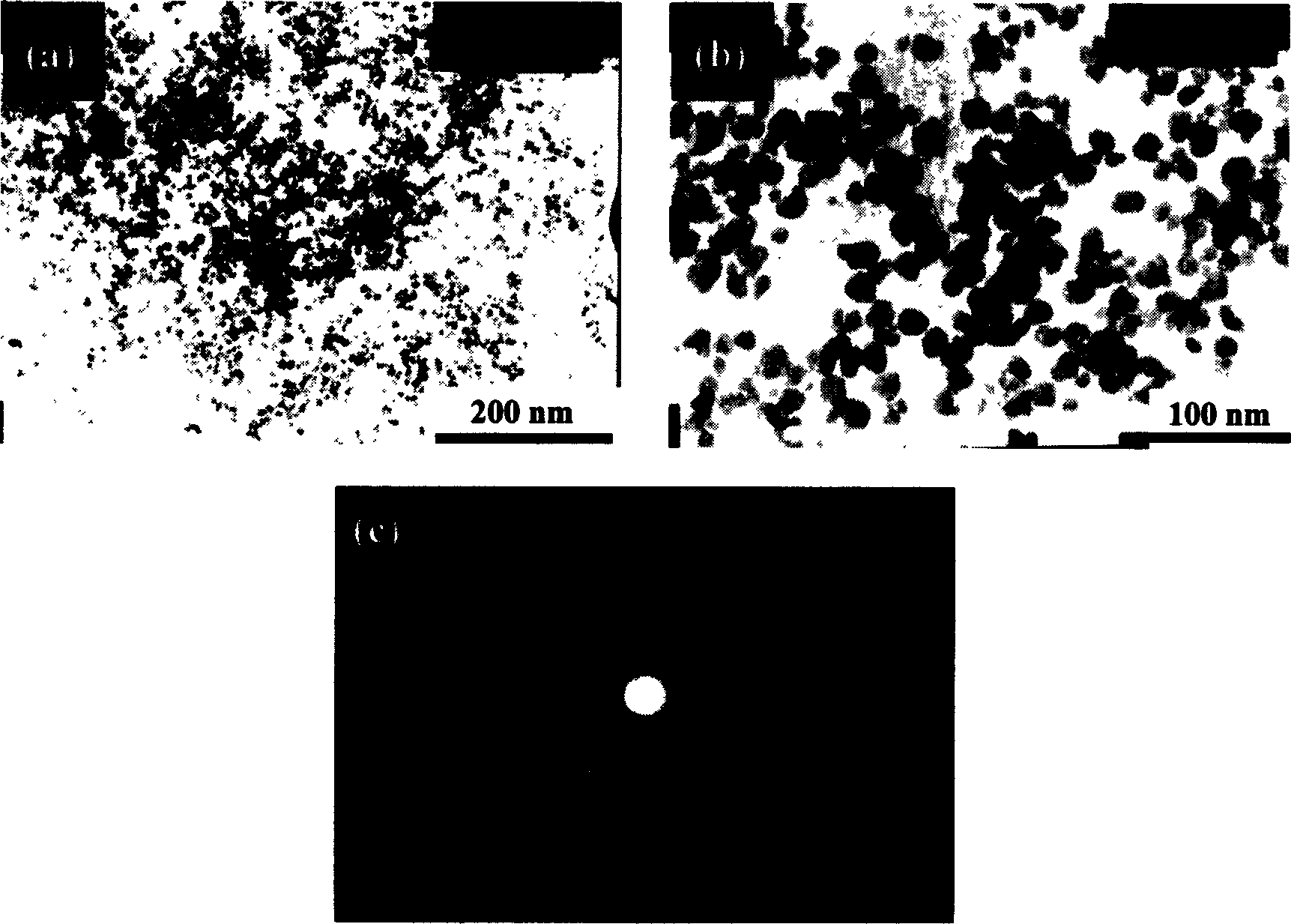

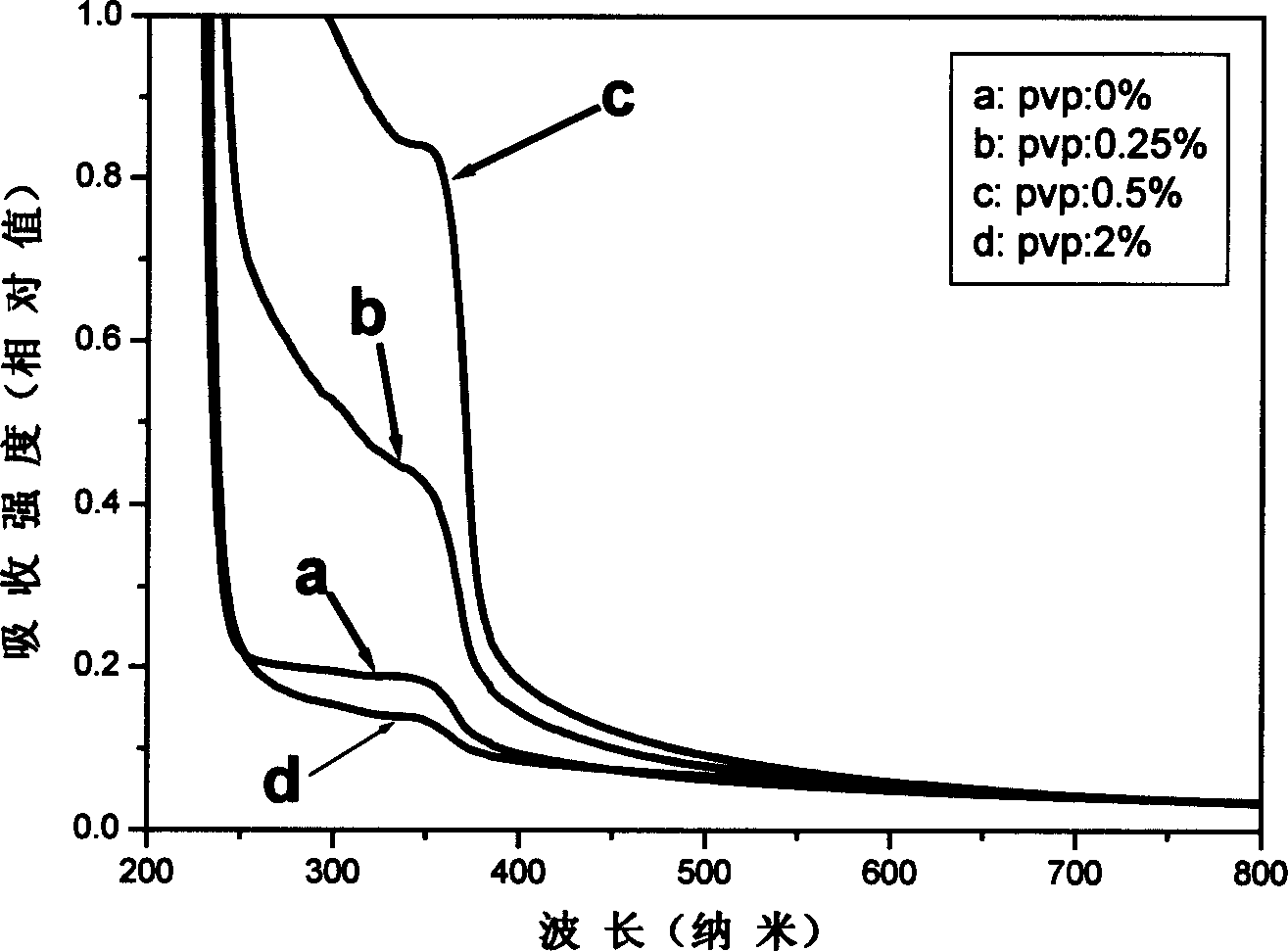

[0025] The X-ray diffraction spectrogram of obtained zinc oxide thin film is as follows figure 1 ,Depend on figure 1 It can be seen that the prepared zinc oxide is hexagonal (36-1451). The particle size of zinc oxide crystals calculated according to the Scherrer formula is 15 nm. Transmission electron microscope pictures as figure 2 a, b, It can be seen f...

Embodiment 2

[0027] ①Preparation of reaction solution: Dissolve 0.0005mol of zinc nitrate and 0.00075mol of hexamethylenetetraammonia in 100ml of methanol solution, then add 0.5g of PVP, stir until the solution is clear, and then prepare a reaction solution.

[0028] ② Synthesis of nano-zinc oxide: Pour the growth reaction solution of zinc oxide nanocrystals prepared above into a tetrafluoroethylene reactor, seal it, heat up to 98°C, and react for 3.5 hours. After the reaction, naturally cool to room temperature and take out the sample Centrifugal separation, natural drying after repeated washing can obtain nano-zinc oxide crystals.

Embodiment 3

[0030] ①Preparation of reaction solution: Dissolve 0.0005mol of zinc nitrate and 0.00075mol of hexamethylenetetraammonia in 100ml of methanol solution, then add 0.5g of PVP, stir until the solution is clear, and then prepare a reaction solution.

[0031] ②Synthesis of nano-zinc oxide: Pour the above-prepared growth reaction solution of zinc oxide nanocrystals into a tetrafluoroethylene reactor, seal it, heat up to 97°C, and react for 4 hours. After the reaction, naturally cool to room temperature and take out the sample Centrifugal separation, natural drying after repeated washing can obtain nano-zinc oxide crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com