CO2 laser tube

A carbon dioxide and laser tube technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of increasing user cost of laser processing equipment, pollution of total reflection mirrors and output mirrors, unstable electrochemical properties, etc. Achieve the effect of highlighting substantive features and progress, improving service life, and stable electrochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

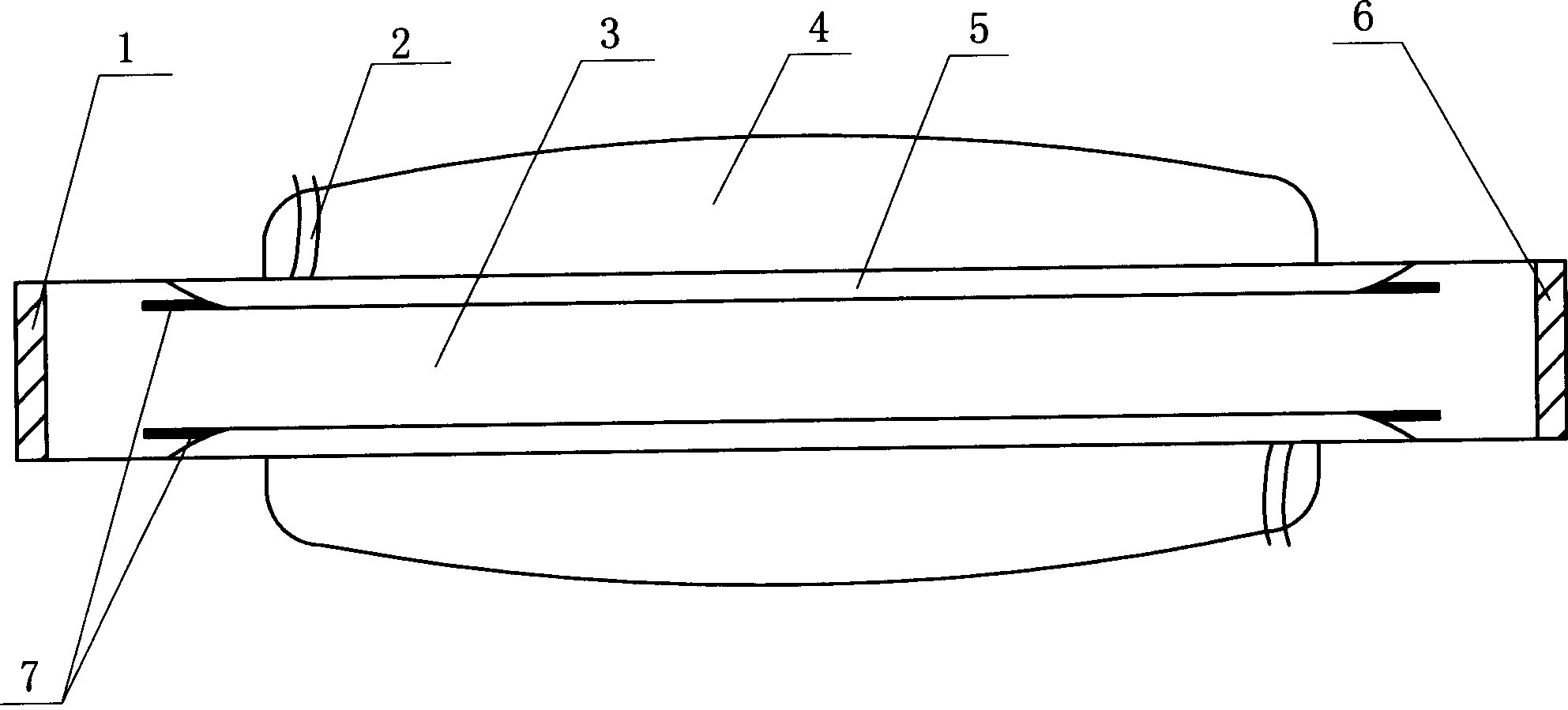

[0007] Accompanying drawing has represented the embodiment of structure of the present invention and laser tube thereof, and its embodiment is described in detail below again, and this carbon dioxide laser tube includes discharge tube 3, gas storage tube 4, water cooling tube 5, output mirror 6, The total reflection mirror 1 and the electrode 7, the discharge tube 3 and the water-cooled tube 5 are placed in the gas storage tube 4, the water-cooled tube 5 is sleeved on the discharge tube 3, and the cooling water nozzle 2 is set on the water-cooled tube 3 to feed water The two ends of the gas storage tube 4 are welded with the water-cooled tube 5, and the electrode 7 is made of titanium or titanium alloy. It can be processed. The manufacturing method of the whole laser tube is the same as in the prior art. The electrodes are electrically connected to the DC power supply, and the titanium or titanium alloy excites the gas in the discharge tube under the action of the DC power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com