Tubular porous titanium membrane-ozone contact reaction device and water treatment method thereof

A technology of ozone contact and reaction device, which is used in oxidation water/sewage treatment, water/sewage treatment, special compound water treatment, etc., to achieve the effect of efficient degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

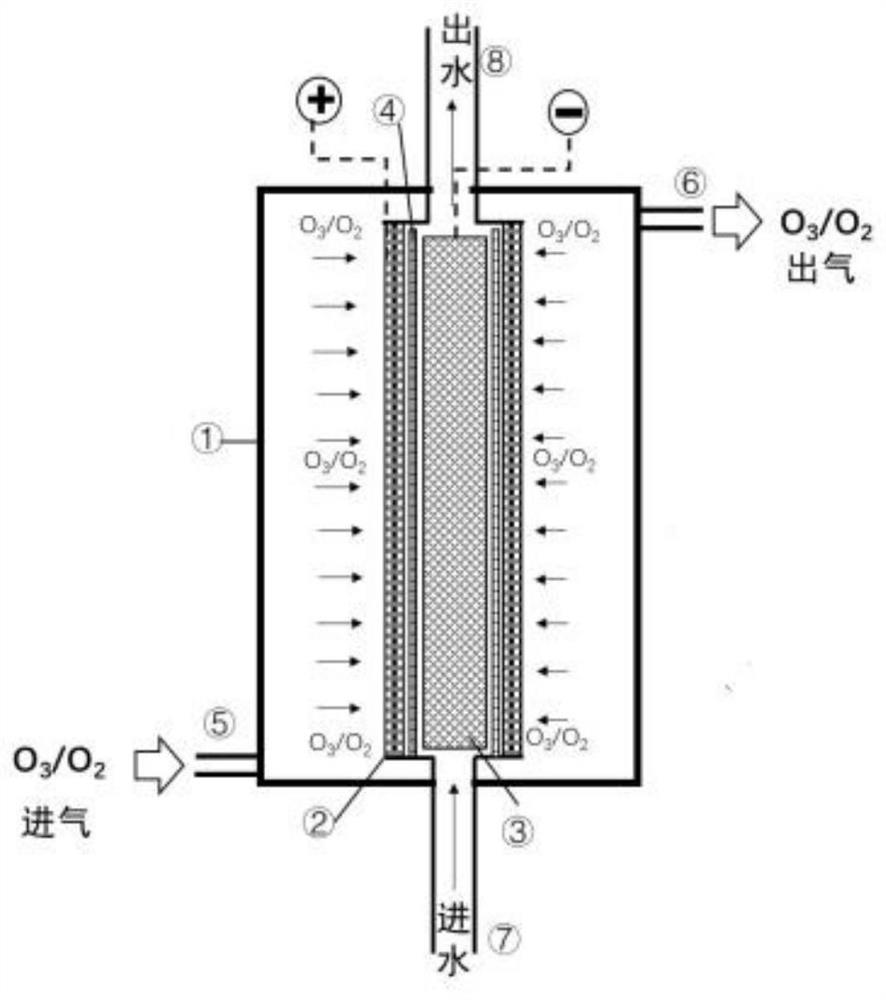

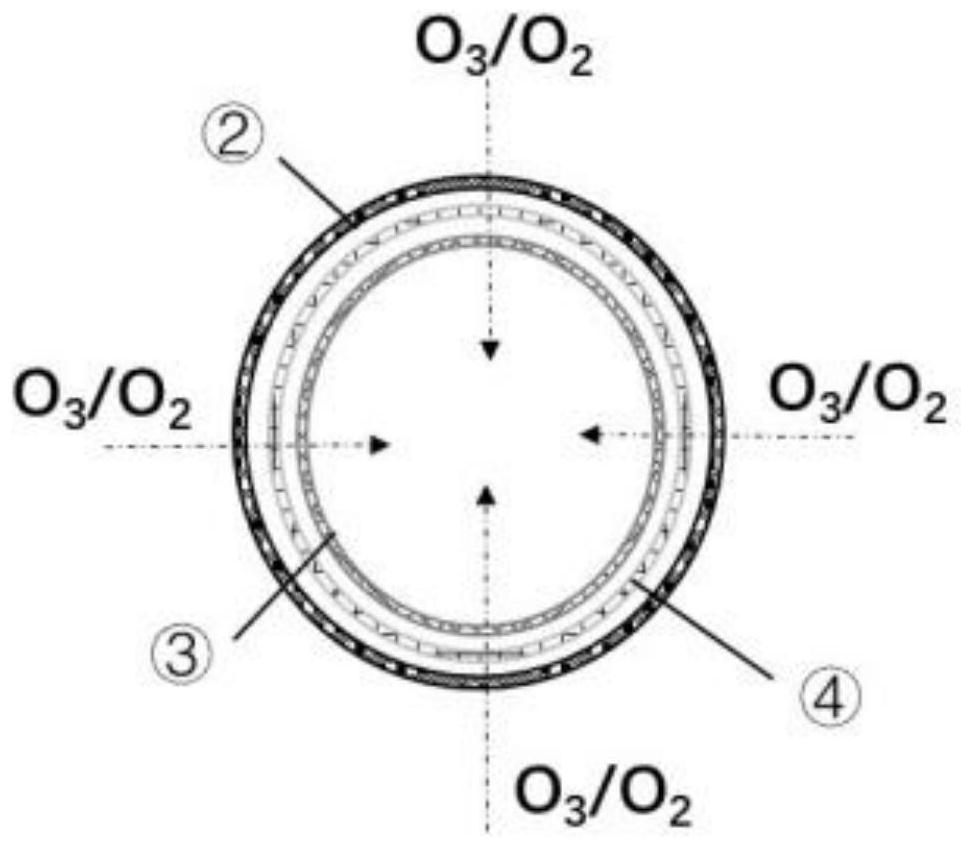

[0034]figure 1 Schematic view of a tubular porous titanium film-ozone contact reaction device,figure 2For electrode top view, referencefigure 1 withfigure 2The apparatus includes: cavity 1, tubular porous titanium film electrode 2, and counter electrode 3. The tubular porous titanium film electrode 2 is disposed at the center of the cavity 1, and the counter electrode 3 is disposed inside the tubular porous titanium film electrode 2, and nylon network 4 is used as a partition material between the two, which is used to prevent short circuits. The bottom and top of the cavity 1 are respectively provided in the vent 5 and the air outlet 6. The tubular porous titanium film electrode 2 is respectively inlet 7 and the water outlet 8, respectively. Tubular porous titanium film electrode 2 as an operating electrode, including tubular porous titanium substrates and TiO loaded on the substrate2The nanometric catalytic layer composition. The tubular porous titanium film electrode 2 has an inne...

Embodiment 2

[0039]figure 1 Schematic view of a tubular porous titanium film-ozone contact reaction device,figure 2For electrode top view, referencefigure 1 withfigure 2The apparatus includes: cavity 1, tubular porous titanium film electrode 2, and counter electrode 3. The tubular porous titanium film electrode 2 is disposed at the center of the cavity 1, and the counter electrode 3 is disposed inside the tubular porous titanium film electrode 2, and nylon network 4 is used as a partition material between the two, which is used to prevent short circuits. The bottom and top of the cavity 1 are respectively provided in the vent 5 and the air outlet 6. The tubular porous titanium film electrode 2 is respectively inlet 7 and the water outlet 8, respectively. The tubular porous titanium film electrode 2 is composed of a working electrode, including a tubular porous titanium substrate, and a graphene catalytic layer loaded on the substrate. The tubular porous titanium film electrode is 3 cm, the wall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com