Highly wearable, highly heat effective non-stick pan and its making process

A production process and high thermal efficiency technology, applied in frying pans, special materials for cooking utensils, household appliances, etc., can solve the problems of hindering heat transfer, non-wear resistance, low welding pass rate, etc., to increase the heat conduction contact area, enhance Wear resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

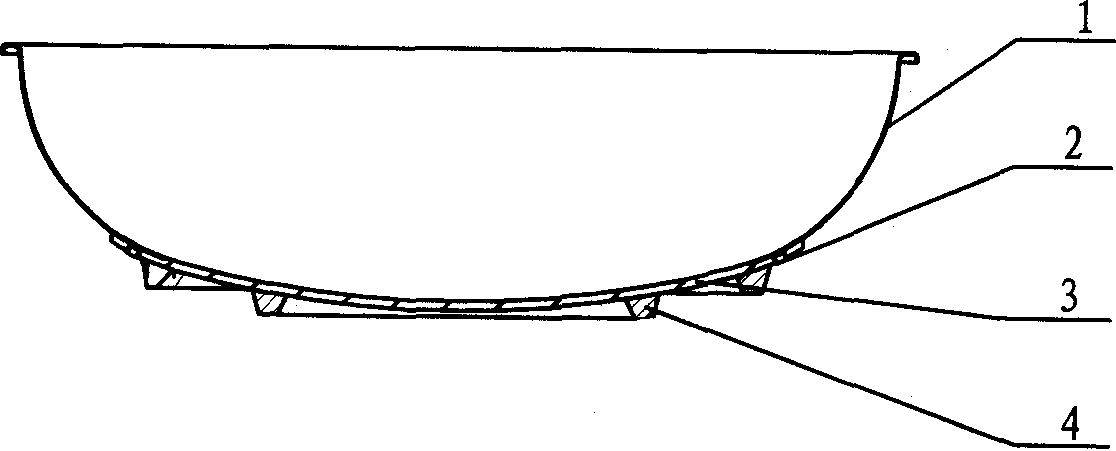

[0019] figure 1 It is the best embodiment of the non-stick electric wok with high wear resistance and high thermal efficiency of the present invention;

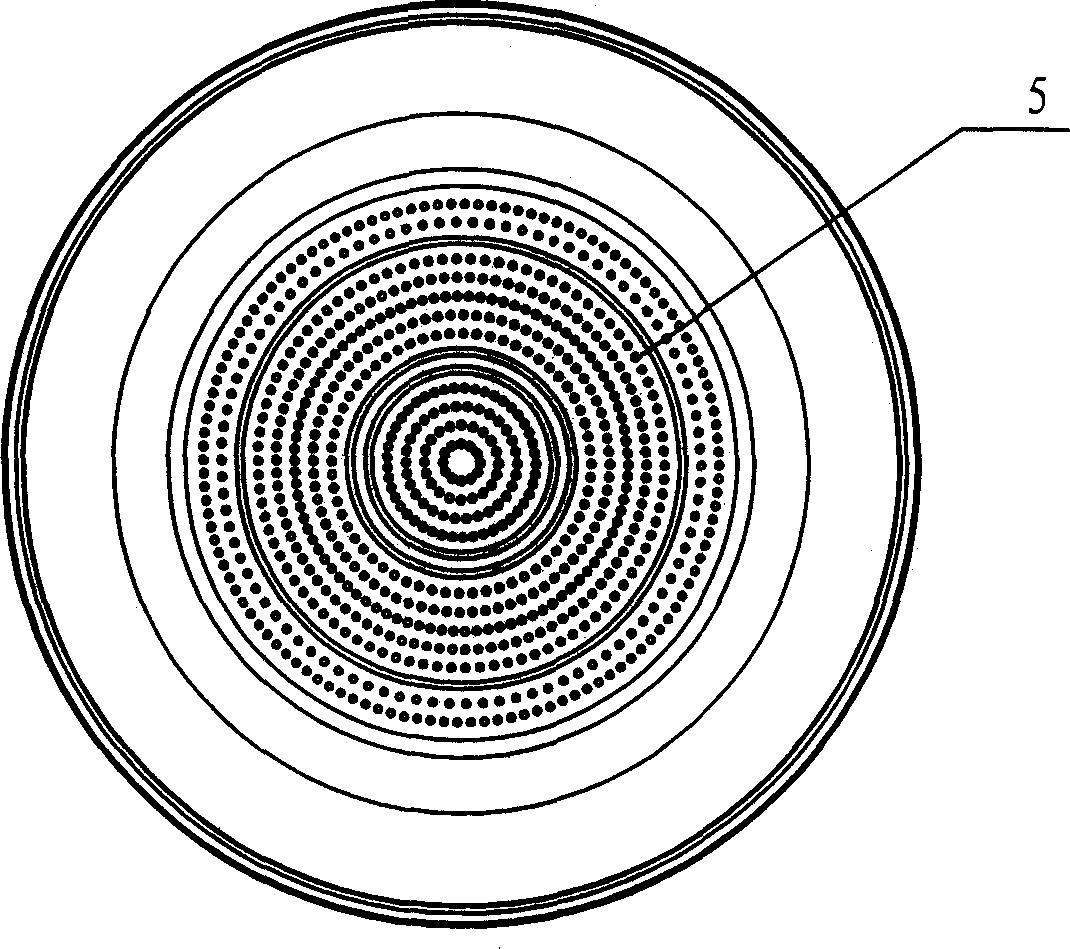

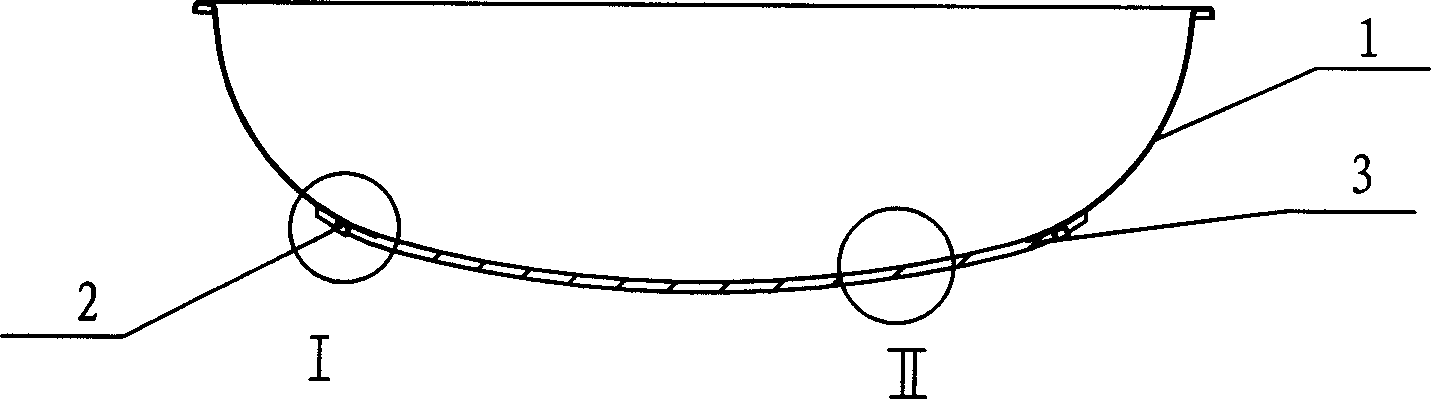

[0020] Figure 2-5 It is the best embodiment of the non-stick frying pan with high wear resistance and high thermal efficiency and its production process of the present invention, below in conjunction with the attached Figure 1-5 The high wear-resistant and high thermal efficiency non-stick frying pan of the present invention and its manufacturing process are further described in detail:

[0021] figure 1 Among them, the pot wall 1 and the pot bottom 3 are two bodies, the pot wall 1 is made of stainless steel material with less heat dissipation, which is made by stretching and molding, and the pot bottom 3 is made of aluminum material with fast heat dissipation and rapid heating. The production process of the non-stick frying pan, first, the two-body pot wall 1 and the pot bottom 3 are riveted-welded-brazed to form a hybr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com