Color liquid crystal display devices

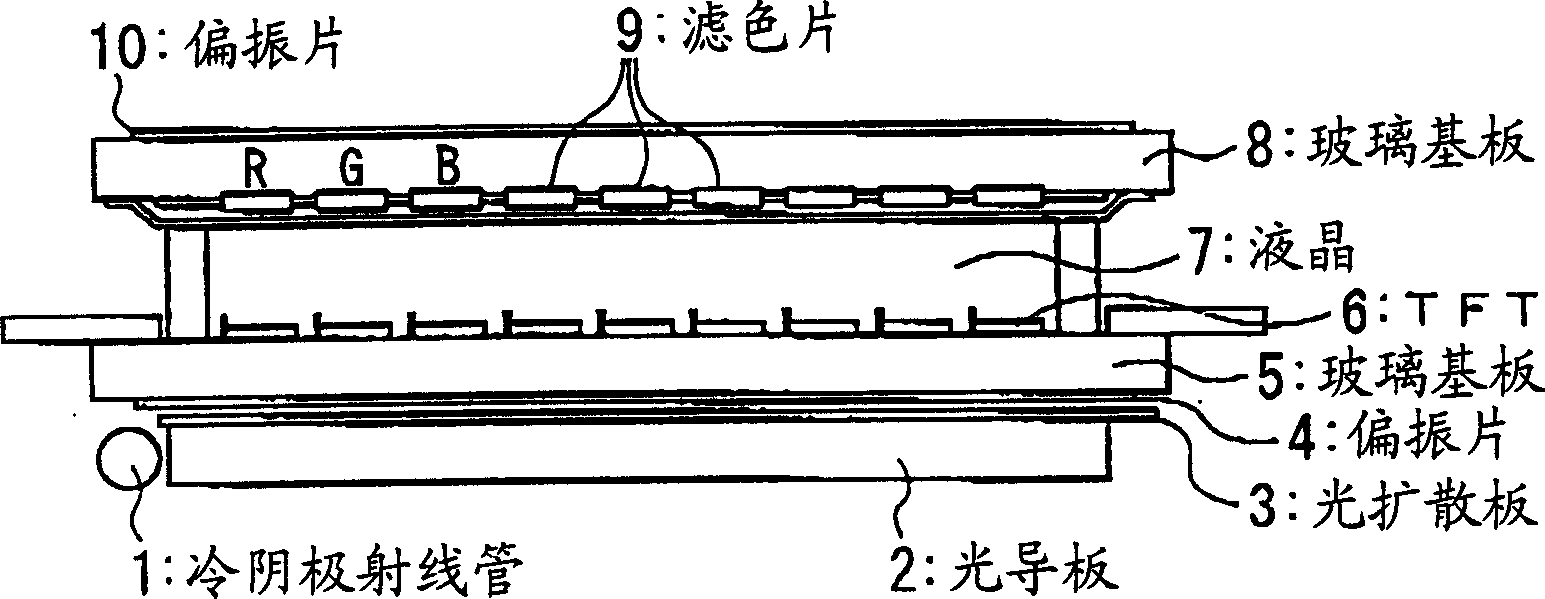

A liquid crystal display device, color technology, applied in light guides, optics, instruments, etc., can solve the problems of not considering color filters, NTSC ultra-high color purity, weak light emission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

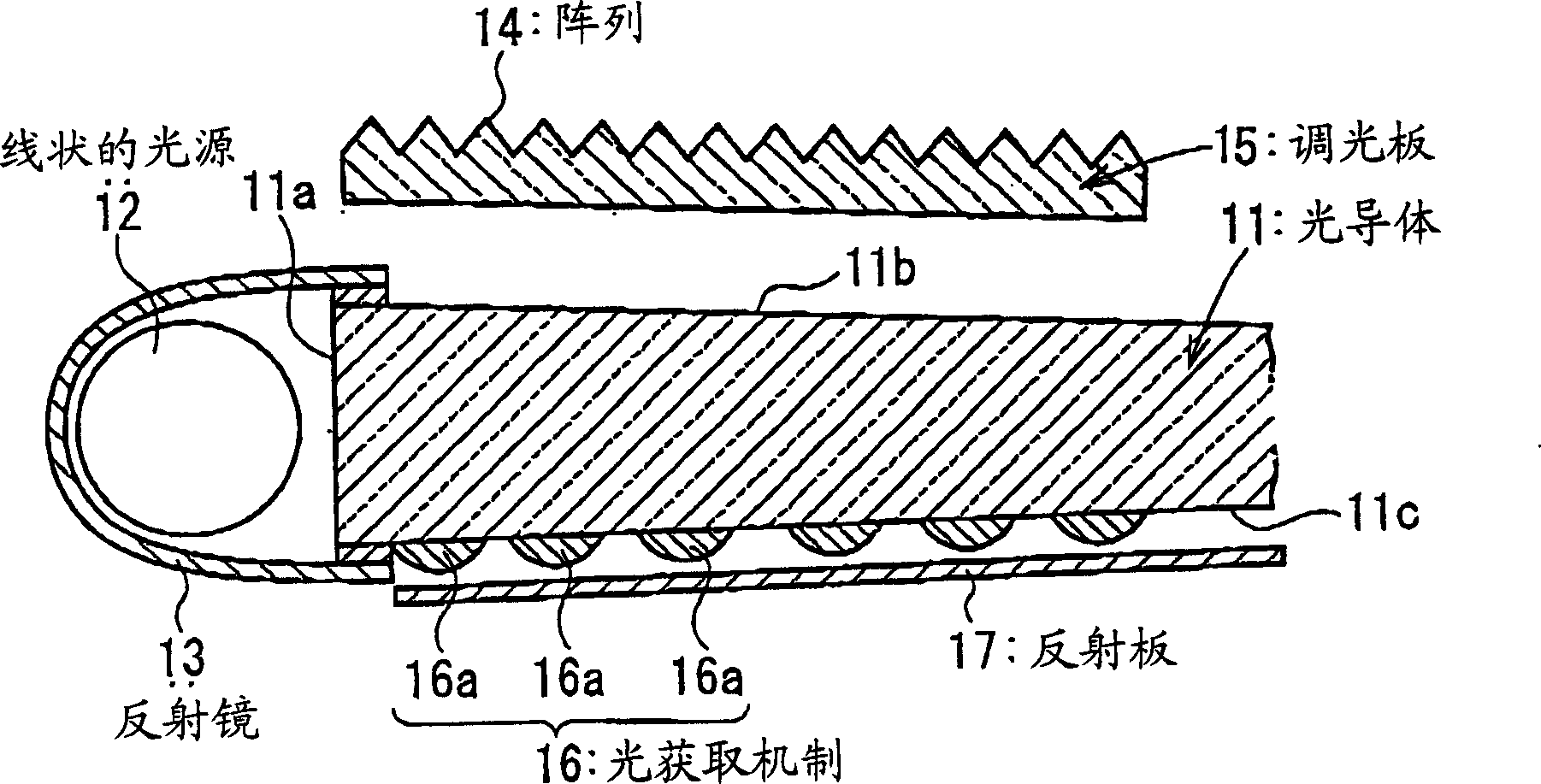

[0247] Manufacturing example 1: Manufacturing of backlight ①

[0248] 52 parts of red phosphor Y 2 o 3 : Eu (manufactured by Kasei Optonics Co., Ltd., trade name "LP-RE1"), 18 parts of Ba 0.9 Eu 0.1 O·(Mg 0.79 mn 0.21 )O·5Al 2 o 3 The green phosphor BaMgAl 10 o 17 : Eu, Mn (manufactured by Kasei Kodenshi Corporation, trade name "LP-G3") and 30 parts of blue phosphor BaMgAl 10 o 17: Eu (manufactured by Kasei Optoelectronics Co., Ltd., trade name "LP-B4"), mixed with nitrocellulose varnish into butyl acetate, fully mixed to make phosphor slurry, and coating the slurry on a tube with a diameter of The inner wall of the 2.3mm glass tube is dried and baked at 620°C for 5 minutes. Then, electrode mounting, evacuation, introduction of Hg and gas, sealing, etc. were carried out in the usual procedure to obtain a cold cathode ray tube for backlight.

[0249] Subsequently, as a photoconductor, a wedge-shaped annular polyolefin resin plate (manufactured by Geon Corporation, J...

manufacture example 2

[0254] Manufacturing example 2: Manufacturing of backlight ②

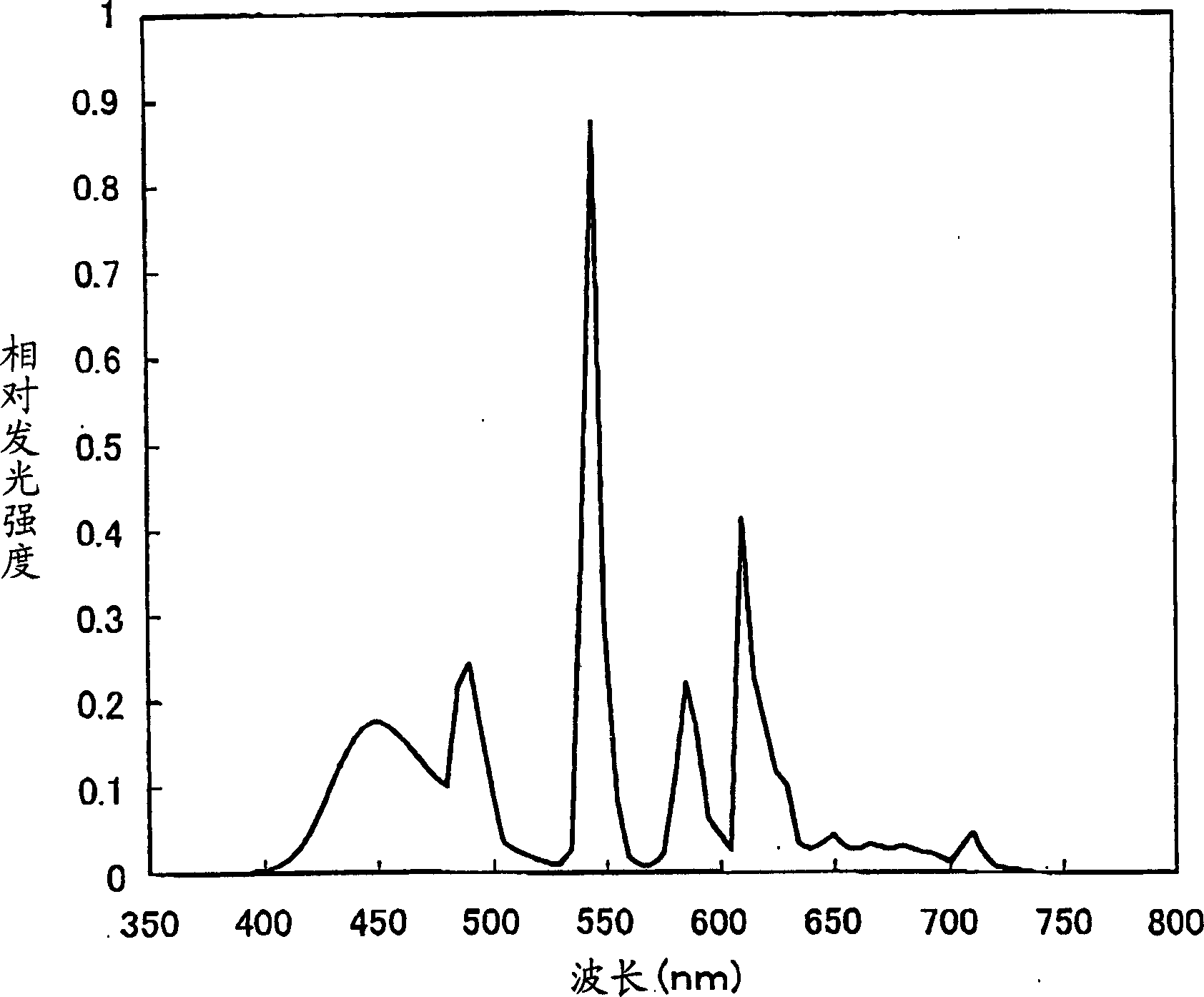

[0255] Using 40 parts by weight of red phosphor YVO 4 :Eu 3+ quasi-phosphor (manufactured by Kasei Photonics, trade name "MGV-620"), 22 parts by weight of green phosphor LaPO 4 : Ce, Tb phosphor (manufactured by Kasei Kodenshi Corporation, trade name "LP-G2") and 38 parts by weight of blue phosphor BaMgAl 10 o 17 : Eu (manufactured by Kasei Photonics Co., Ltd., trade name "LP-B4"), except that, it was produced in the same manner as in Production Example 1 to obtain a cold cathode ray tube for backlight, which was processed in the same manner as in Production Example 1 , get the backlight ②. The resulting relative luminescence spectra of the backlight are shown in Figure 6 .

[0256] The main emission wavelengths of the backlight ② are red: about 620 μm, blue: about 450 μm, and green: about 545 μm.

manufacture example 3

[0257] Manufacturing example 3: Manufacturing of backlight ③

[0258] Using 40 parts by weight of red phosphor YVO 4 :Eu 3+ quasi-phosphor (manufactured by Kasei Photonics, trade name "MGV-620"), 22 parts by weight of Ba 0.9 Eu 0.1 O·(Mg 0.79 mn 0.21 )O·5Al 2 o 3 The green phosphor BaMgAl 10 o 17 : Eu, Mn (manufactured by Kasei Kodenshi Corporation, trade name "LP-G3") and 38 parts by weight of blue phosphor BaMgAl 10 o 17 : Eu (manufactured by Kasei Photonics Co., Ltd., trade name "LP-B4"), except that, it was produced in the same manner as in Production Example 1 to obtain a cold cathode ray tube for backlight, which was processed in the same manner as in Production Example 1 , get the backlight ③. The resulting relative luminescence spectra of the backlight are shown in Figure 7 .

[0259] The main emission wavelengths of the backlight ③ are red: about 620 μm, blue: about 450 μm, and green: about 515 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com