Treating method and apparatus for seawater desalting

A seawater and treatment method technology, applied in chemical instruments and methods, general water supply conservation, water/sewage multi-stage treatment, etc. The effect of reducing energy consumption, improving recovery rate and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

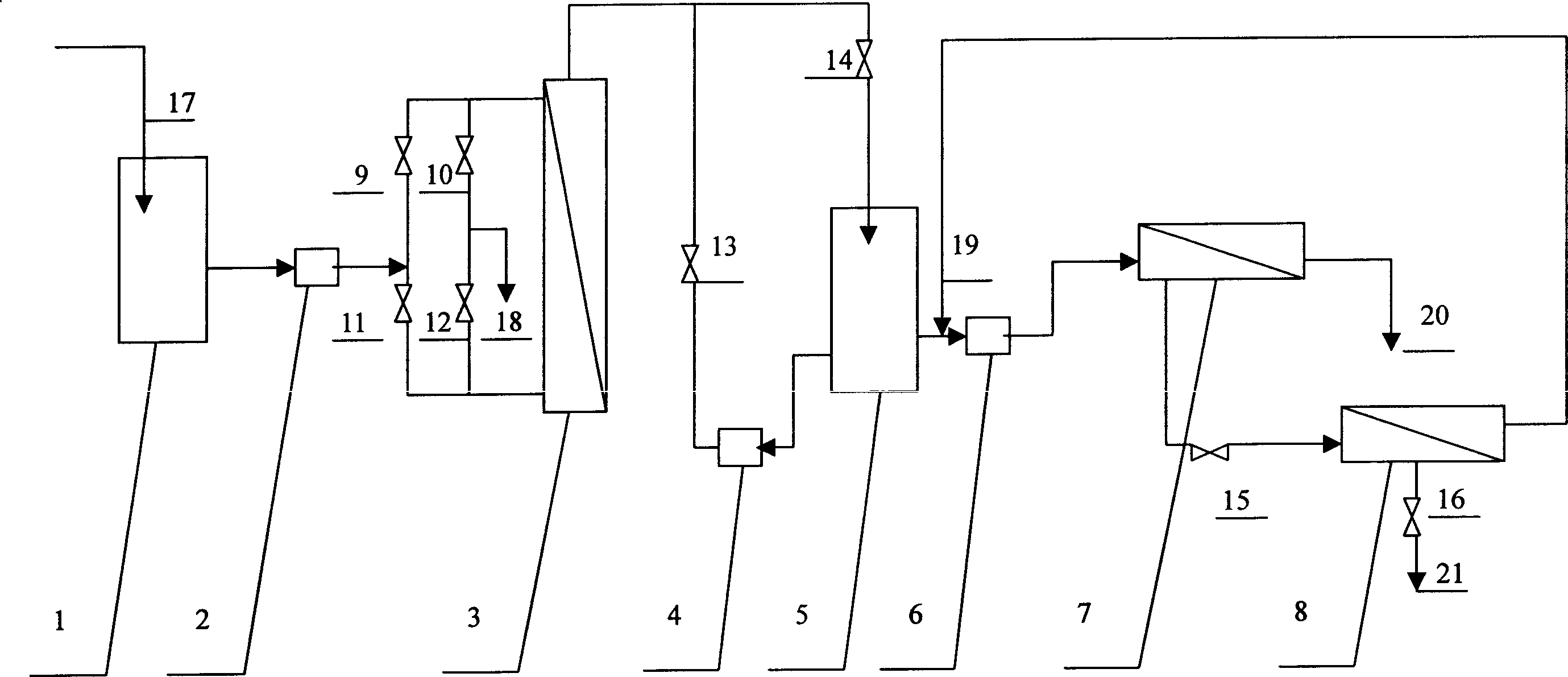

[0015] Refer to attached figure 1 , the seawater desalination treatment equipment of the present invention comprises a raw water tank 1, a booster pump body 2, an ultrafiltration device 3, a cleaning pump body 4, an intermediate water tank 5, a high-pressure pump body 6, a reverse osmosis device 7, a nanofilter 8, etc., they connected in turn. The inlet of the raw water tank 1 is connected with the sea water intake, the outlet of the raw water tank 1 is connected with the inlet of the booster pump body 2, the outlet of the booster pump body 2 is connected with the water inlet of the ultrafiltration device 3, and the water produced by the ultrafiltration device 3 is obtained by The outlet flows into the intermediate water tank 5, the outlet of the intermediate water tank 5 is connected to the inlet of the high-pressure pump body 6, the water outlet of the high-pressure pump body 6 is connected to the water inlet of the reverse osmosis device 7, and the fresh water outlet of the...

Embodiment 2

[0017] Refer to attached figure 1 , adopt the equipment of embodiment one, choose suitable seawater concentration 28299mg / L, seawater is first pumped into raw water tank 1, when storing a certain amount of seawater in raw water tank 1, valve 9,11,14 is opened, valve 10,12 , 13 off. Start the booster pump body 2, and pump the seawater into the full filtration ultrafiltration device 3 for pretreatment. The pretreated seawater has removed suspended solids, clay, silt, marine organisms, and other substances in the seawater. This can effectively prevent various suspended solids and scale-forming components in seawater from polluting the reverse osmosis membrane, resulting in a decline or damage to the membrane performance. The difference between the full-filtration ultrafiltration membrane treatment and the cross-flow filtration treatment technology is that the full-filtration ultrafiltration membrane does not discharge the concentrated solution, and all the water passes through ...

Embodiment 3

[0021] Refer to attached figure 1 , using the same method and equipment as in Example 2, selecting a suitable seawater concentration of 28299mg / L, the operating pressure of the reverse osmosis device 7 is 7.0Mpa, the operating pressure of the nanofilter 8 is 4.0Mpa, and the product water recovery rate at this time is 61.0%, and the salt removal rate is 98.96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com