Preparing method for temperature controlling ionic absorbing fibre

A technology of ion adsorption and fiber, which is applied in the fields of radiation chemistry and chemical engineering, and can solve the problems of high consumption of pure water, waste liquid pure water consumption, waste of water resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

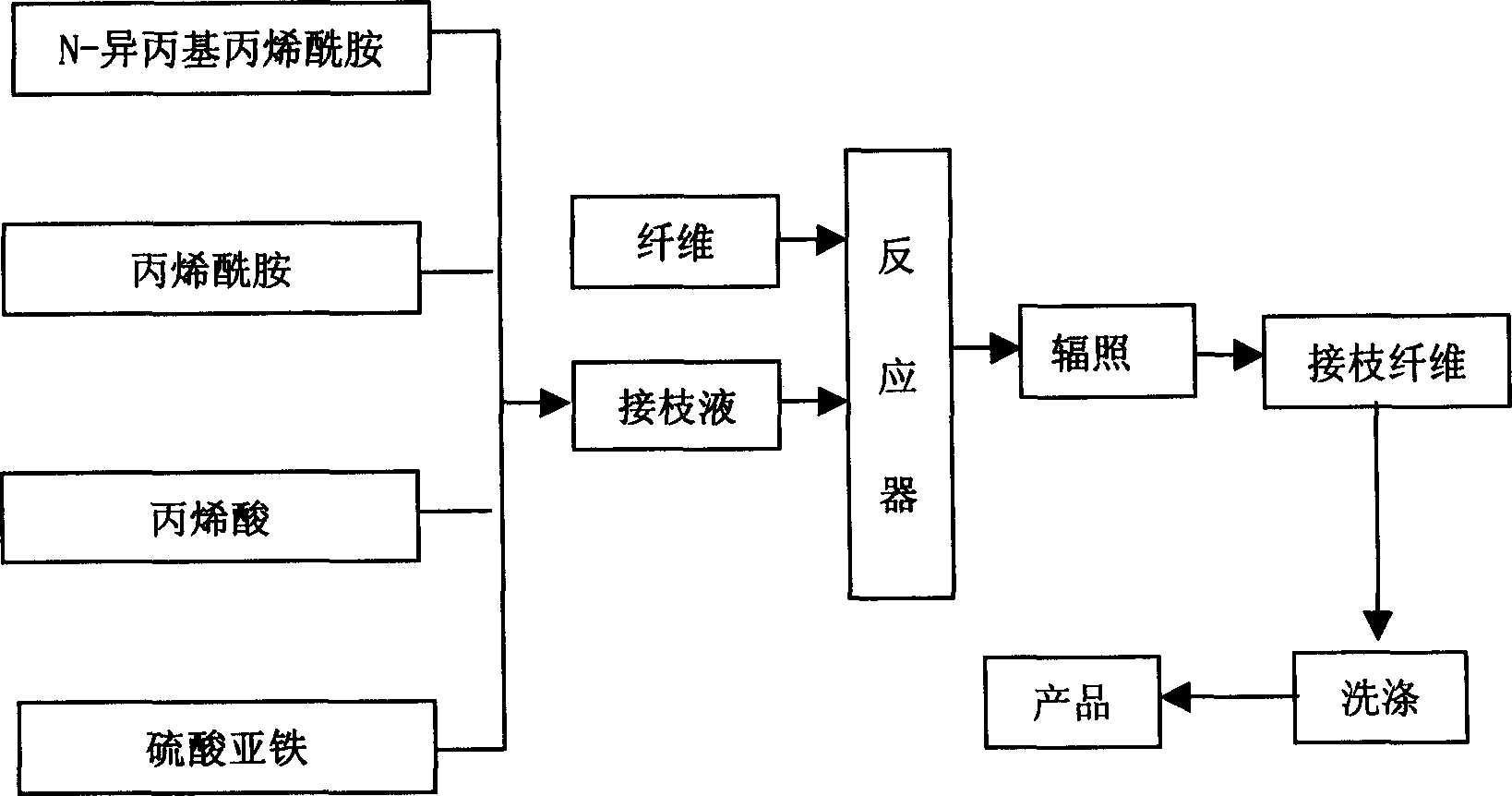

[0016] Embodiment one: see figure 1 , this embodiment adopts co-irradiation grafting method to prepare temperature-controlled ion adsorption fiber: immerse polypropylene (PP) fiber in the grafting solution, and then send the reaction system into the irradiation hall for irradiation through the transmission device, and the irradiation source adopts γ-rays, the dose is 10kGy. After irradiation, the fibers are taken out, and the monomers and homopolymers on the surface are washed away to obtain graft-modified PP fibers with temperature-controlled ion adsorption-desorption functions. The formula of the grafting solution is: N-isopropylacrylamide (NIPAAm) 5%, acrylamide (AAm) 3%, acrylic acid 1%; copper chloride CuCl 2 0.01%, the solvent is deionized water. The grafting ratio of 25 is appropriate.

Embodiment 2

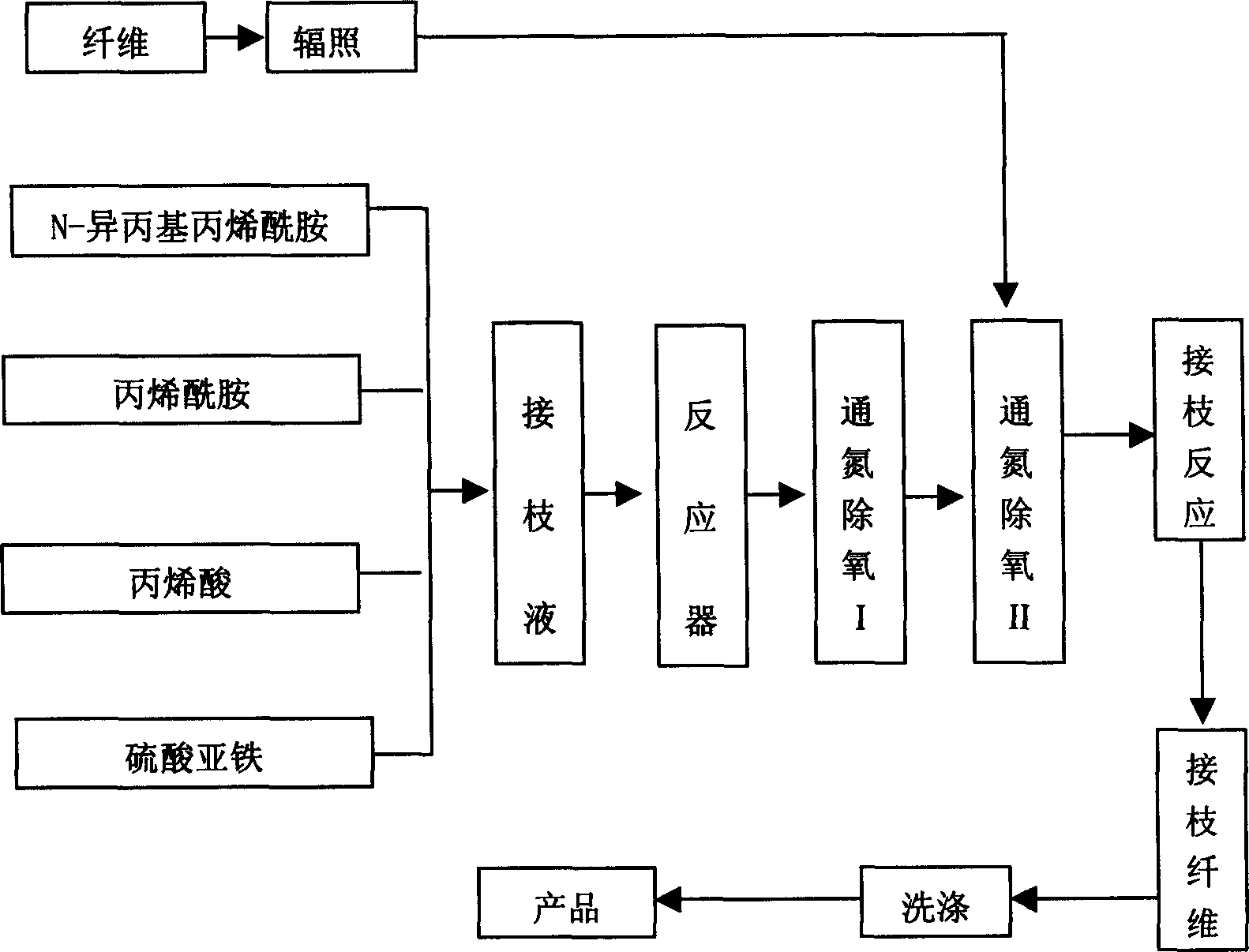

[0017] Embodiment two: see figure 2 , In this example, pre-irradiation grafting is used to prepare temperature-controlled ion-adsorbing fibers: polypropylene (PP) fibers are introduced into a radiation field through an irradiation transmission device for irradiation, and the irradiation source is γ-rays with a dose of 60 kGy. Inject the grafting liquid into the reactor, immerse the pre-irradiated fiber in the grafting liquid after nitrogen deoxygenation for 10 minutes, pass nitrogen deoxygenation again for 10 minutes, then place the reactor at an appropriate temperature for grafting reaction, The reaction temperature was 60°C, and the reaction time was 8 hours. After the reaction, the fiber is taken out, and the homopolymer and monomer on the surface are washed away to obtain a graft-modified PP fiber with temperature-controlled ion adsorption-desorption function. The formula of grafting liquid is: N-isopropylacrylamide (NIPAAm) 5%; Acrylamide (AAm) 3%; Acrylic acid (AAc) 1%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com