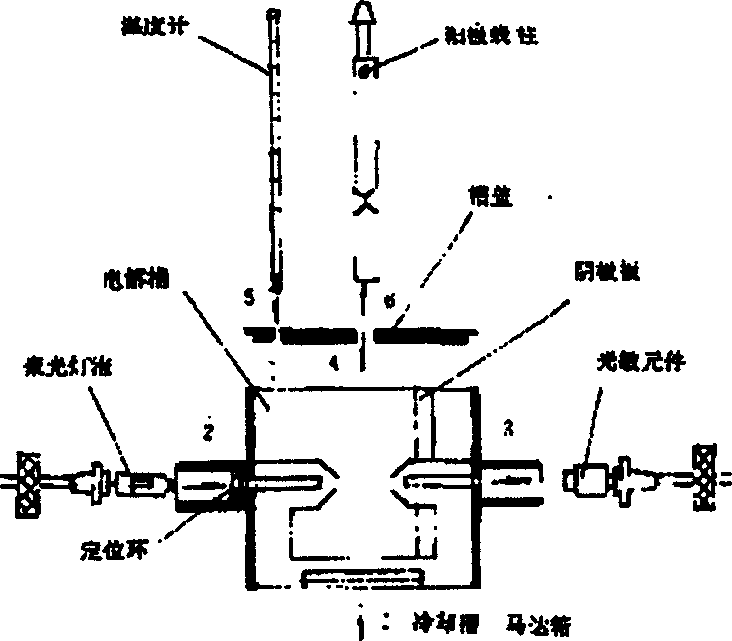

[0002] At present, in most colleges and research institutes in my country, most of the electrolytic double-spray instruments used to make TEM samples are domestically produced, and the main one is the MTP-1 electrolytic double-spray

sample preparation instrument of Shanghai Jiaotong University, such as figure 1 As shown, there are the following disadvantages: (1) Compared with foreign countries, the electrolytic

polishing current range is narrower (0-15mA range), and the corresponding parameters of foreign equipment are generally an

order of magnitude higher (0-400mA range). When the double-jet instrument is used to make thin film samples for

transmission electron microscopy, the range of electrolytic current at

room temperature is strictly limited. Domestic colleges and research institutes mainly reduce the temperature of the

electrolyte (-15°C to -5°C) to achieve The purpose of reducing the

electrolysis current of the

electrolyte is to obtain a satisfactory

metal thin film sample, but the experimental

temperature control process is cumbersome, and the low temperature condition is very unfavorable to the service life of the electrolytic double jet instrument, especially the damage to the instrument caused by

liquid nitrogen quenching , mixing

liquid nitrogen into the electrolyte has a significant

cooling effect, but changes the effective concentration of the electrolyte; (2) Due to the rapid flow of the electrolyte, it is difficult for the double-jet electrolytic

polishing to appear the

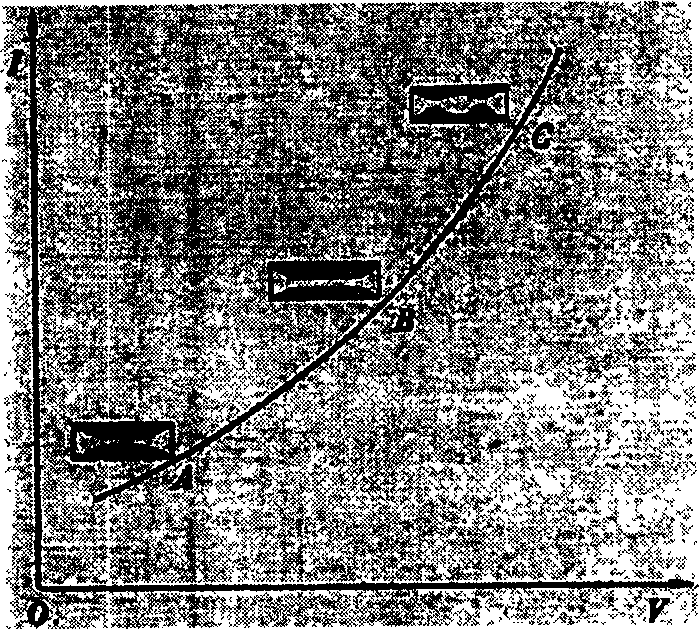

limiting current plateau area pointed out by the theory, and its I-

V curve is almost in a straight line, such as figure 2 As shown, the shape of the polished sample is different in each area of the curve:

corrosion occurs in the low-

voltage area; the

voltage is too high and the edge of the sample is perforated, and the film quality is not good; only the

thinning at B is the best, and a large flat film can be obtained. But it is not easy to explore; (3) The material of the sample itself and its physical state, the composition of the electrolyte, the relationship between temperature and

voltage and current values, the size of the instrument

nozzle, the distance between electrodes, the shape of the sample holder and the flow rate of the electrolyte are all important factors for sample preparation. There are different degrees of influence, and the

product design is difficult to meet or take into account. According to user reports, the

nozzle of the instrument made of plastic is aging and deformed after being used for a long time, and the liquid columns ejected from the two nozzles cannot be accurately docked; (4) The alarm sensitivity of the photosensitive device is poor, The formation of micropores by

visual inspection does not necessarily indicate the formation of sufficiently large or sufficiently thin areas; (5) Once the optimal polishing conditions are determined and the polished sample is pierced, it is recommended to clean the sample immediately without removing the voltage, but the existing models The design of the sample holder of the sample preparation device makes it too late for the sample to be cleaned quickly, and the thin area on the edge of the

small hole is corroded

[0003] Li Qiaoling, Ye Yun,

North China Institute of Technology. "Preparation of

metal permeated thin film samples from a mixture of

perchloric acid and glacial

acetic acid at

room temperature", Communication of Analytical and Testing Instruments, 1995, 6(2): 93-94, using 0.46mol / L HClO 4 -16.7mol / L HAc

electropolishing solution was used to conduct experiments, and the

electropolishing parameters for preparing metallized film samples at

room temperature (5~15°C) were determined, which were prepared by Bollmann method (edited by Chen Shipu, Wang Yongrui.

Electron Microanalysis of Metals. Beijing : Mechanical Industry Press, 1982: 102)

Electron microscope thin film samples provide a method for selecting electrolytic parameters, which obviously does not have universal applicability to materials; and textbooks think that preparing thin film samples for

transmission electron microscopy generally uses 12mol / L HClO 4 The electrolytic polishing solution (Li Shutang.

Metal X-

ray and

electron microscopic analysis. Beijing:

Metallurgical Industry Press, 1980: 224) composed of absolute

ethanol with a

volume fraction of 90% is carried out at -10~-20°C , many documents give which kind of material should use which kind of electrolyte and its applicable temperature (Wu Xingfang, Liu Delu. Practical Methods of

Electron Microanalysis. Beijing:

Metallurgical Industry Press, 1998: 12-13; Li Qiaoling, Ye Yun .Zhao Xingguo.Research on the development and parameter selection of room temperature electrolytic polishing fluid. Shanxi Machinery, 1997, 4(97): 12-16; Ma Shubo. Physical testing of sample preparation technology for transmission

electron microscope, 1995, 1: 42-45), experimenter It is not easy to determine the parameters of

electropolishing Login to View More

Login to View More  Login to View More

Login to View More