Transparent acid gel and its preparation method

A hyaluronic acid and gel technology, which is applied in the field of hyaluronic acid gel and its preparation, can solve the problems of gel products such as white appearance, short storage period, and multiple proteins, so as to improve product quality, prevent chain breakage, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 10g of hyaluronic acid in 1000ml of water to form a 1% solution, add 5mg of BD-2 deproteinized product from Boda Company of Tianjin University, stir well, let stand until precipitation appears, and then filter. Add 3000ml of 95% edible ethanol to the filtrate, stir vigorously until a white precipitate appears, filter, and vacuum-dry the filter cake. 9.8 g of hyaluronic acid with a protein content of less than 0.1% were obtained.

[0030] Cross-linking reaction:

[0031] Example 1

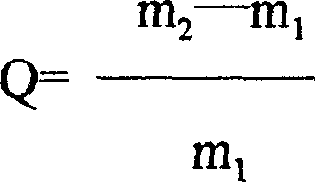

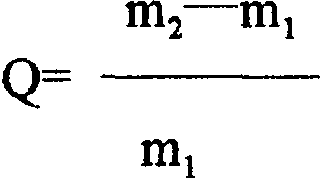

[0032] Dissolve 2 g of deproteinized hyaluronic acid prepared in Example 1 in deproteinized pretreatment in 24 ml of 1% NaOH, add 40 mg of ethylene glycol glycidyl ether, react at 15 ° C for 2 hours, let stand overnight, and then use Soak in deionized water, adjust to neutral with HCl, after fully soaking, the weight of the water-absorbing gel is 1000g, so the water absorption rate formula Q = m 2 ...

Embodiment 2

[0034] Dissolve 2 g of the deproteinized hyaluronic acid prepared in Example 1 of the deproteinized pretreatment in 20 ml of 1.5% NaOH solution, add 100 mg of 1,4-butanediol glycidyl ether, stir well and place it at 20°C for 24 hours to react The product is placed in ion-free water, and HCl is added to adjust the pH value to neutrality. After fully soaking, the water-absorbing gel is 840g. From the water absorption formula, it can be seen that the resulting gel product is a hyaluronic acid gel with a water absorption rate of 420 times (see Table 1).

Embodiment 3

[0036] Dissolve 2 g of the deproteinized hyaluronic acid prepared in Example 1 of the deproteinized pretreatment in 20 ml of 1% HCl solution, add 200 mg of 1,4-butanediol glycidyl ether, react at 35 ° C, and let stand after 4 hours Overnight, then put the reactant into deionized water, adjust neutrality with NaOH, after fully soaking, the water-absorbing gel weight is 700g, as can be seen from the water absorption formula, the resulting gel product is a hyaluronic acid gel with a water absorption rate of 350 times (see table 1).

[0037] hyaluronic acid

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com