Catalyst for preparing high surface area nitride or carbide by plasma method

A technology of plasma and nitride, applied in the direction of physical/chemical process catalysts, catalyst activation/preparation, chemical/physical processes, etc., can solve the problems of high temperature in the preparation process, unstable product performance, complex reaction process, etc. Effects of shorter time, lower cost, and lower reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

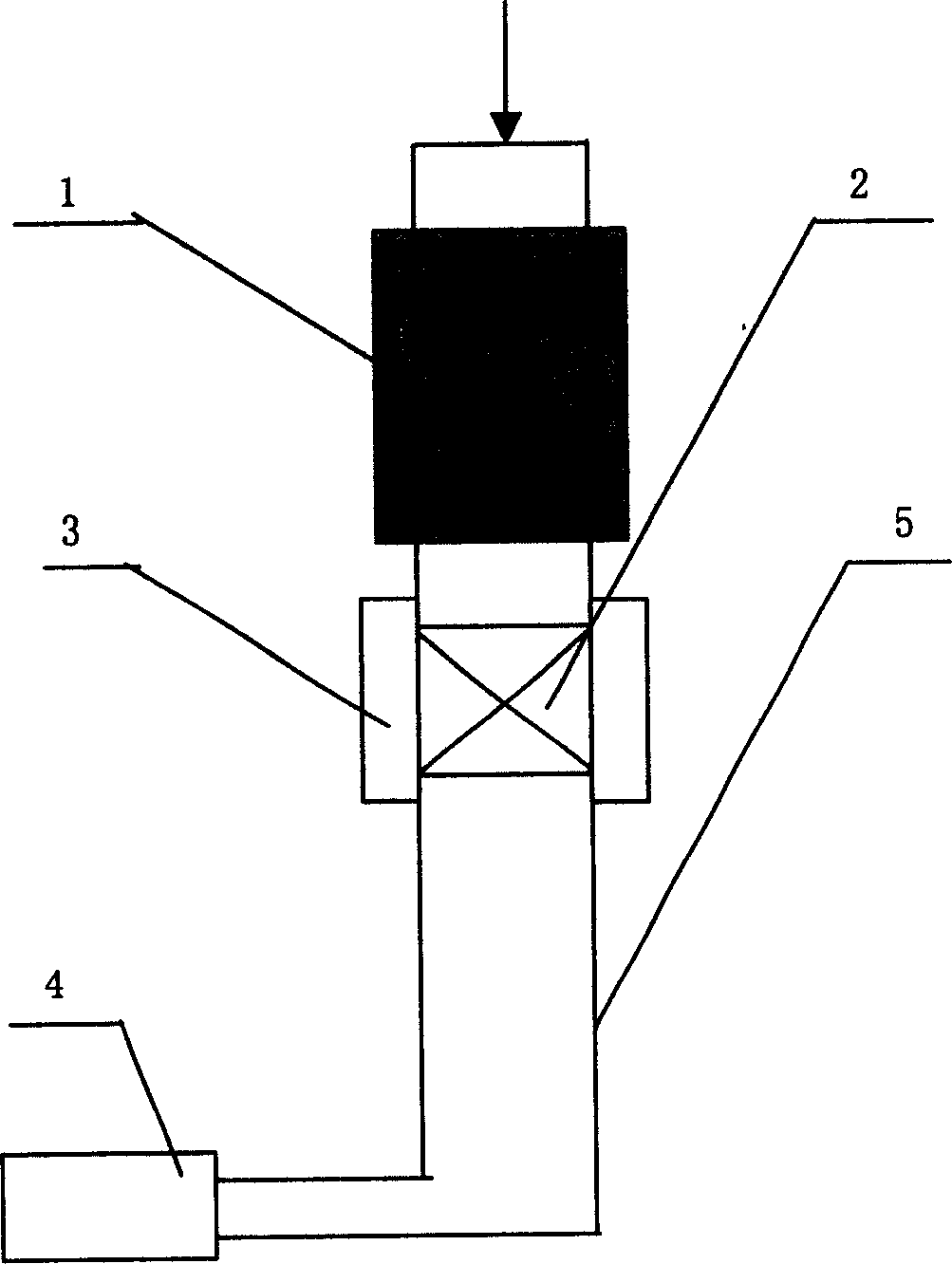

[0009] Example 1: 20 grams of Mo are loaded into the fixed bed (2) 2 o 3 , and heated with a heating furnace (3), and at the same time with a reaction space velocity of 50h -1 Nitrogen gas is fed into the quartz tube fixed bed reactor (5), the gas first passes through the radio frequency plasma generator (1), and the nitrogen-containing plasma generated reacts with the transition metal oxide placed on the fixed bed. During the reaction, the reaction bed temperature was controlled at 400°C, the radio frequency power was 100W, and the composition of the tail gas was detected by chromatography-mass spectrometer (4) to control the reaction process and product quality. After 3 hours of reaction time, the molybdenum nitride catalyst was obtained. The specific surface area is 58m 2 / g.

example 2

[0010] Example 2: 20 grams of Mo are loaded into the fixed bed (2) 2 o 3 , and heated with a heating furnace (3), and at the same time with a reaction space velocity of 50h -1 Pass into the mixture of nitrogen and hydrogen to quartz tube fixed bed reactor (5), nitrogen and hydrogen mol ratio are 3, gas first passes through radio frequency plasma generator (1), the plasma containing nitrogen that produces is placed on fixed bed reactions of transition metal oxides. During the reaction, the reaction bed temperature was controlled at 400°C, the radio frequency power was 100W, and the composition of the tail gas was detected by chromatography-mass spectrometer (4) to control the reaction process and product quality. After 3 hours of reaction time, the molybdenum nitride catalyst was obtained. The specific surface area is 79m 2 / g.

example 3

[0011] Example 3: Load 20 grams of WO on the fixed bed (2) 3 , and heated with a heating furnace (3), and at the same time with a reaction space velocity of 100h -1 Pass into the mixture of nitrogen and ammonia to quartz tube fixed-bed reactor (5), nitrogen and ammonia mol ratio are 3, gas first passes through radio frequency plasma generator (1), the plasma containing nitrogen of generation and place Transition metal oxide reaction on a fixed bed. During the reaction, the temperature of the reaction bed is controlled at 400°C, the radio frequency power is 200W, and the composition of the tail gas is detected by chromatography-mass spectrometer (4) to control the reaction process and product quality. After 3 hours of reaction time, the tungsten nitride catalyst is obtained. The specific surface area is 89m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com