Decomposition liquid recovering technology in heavy sodium carbonate

A technology of heavy soda ash and decomposition solution, which is applied in alkali metal compounds, alkali metal carbonates, inorganic chemistry, etc., can solve problems such as environmental pollution and waste of resources, and achieve the goals of avoiding environmental pollution, increasing production, and maintaining water balance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

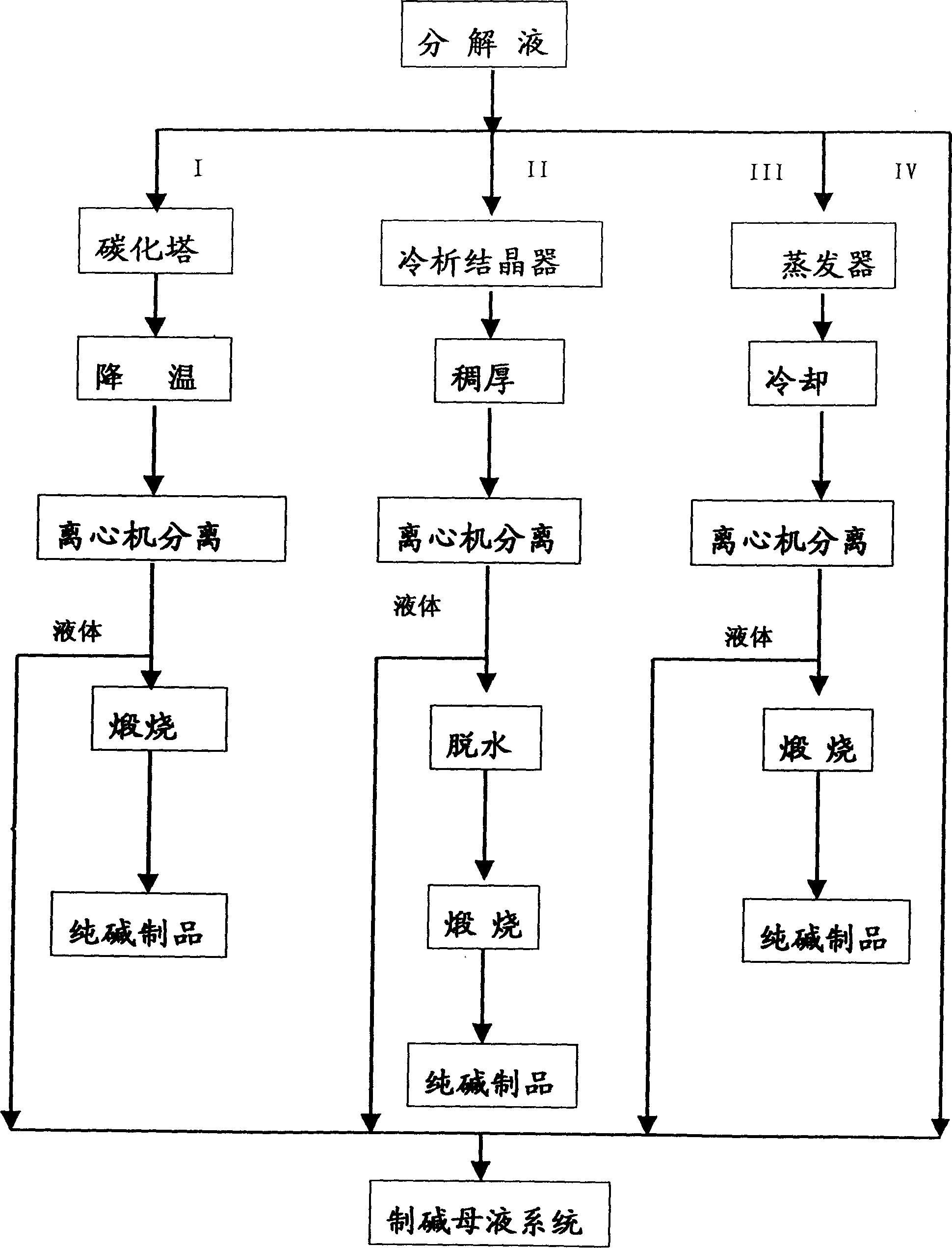

Method used

Image

Examples

Embodiment 1

[0065] Carbonization of decomposition liquid to produce Na 2 CO 3 :

[0066] The steam direct calcination reactor discharges 2000 liters of decomposition liquid at a temperature of 90°C, in which Na 2 CO 3 178g / l, NaHCO 3 It is 12g / l, and NaCl is 80g / l. After being cooled by water to 60°C, it enters the carbonization tower. CO 2 The gas with a content of 99% flows countercurrently from the bottom, that is, the contact reaction of the decomposition liquid. Under the conditions of temperature 55-60°C and pressure 0.3Mpa, Na 2 CO 3 Continuously synthesize NaHCO 3 , when Na in the mother liquor 2 CO 3 Carbonation ends when the concentration drops to 8 g / l. The carbonized liquid is taken out and cooled down to 30°C, and then enters the centrifuge for separation. The isolated solid weighs 217 kg, of which NaHCO 3 The content is 81%, Na 2 CO 3 content of 2%, NaCl content of 1.2%, H 2 The O content is 15.7%. After the solid is directly calcined by steam, washed, hydrate...

Embodiment 2

[0068] Decomposition liquid cold analysis to produce Na 2 CO 3 :

[0069] 2,000 liters of 100°C decomposition liquid discharged from the direct steam calcination reactor, of which Na 2 CO 3 168g / l, NaHCO 3 It is 9g / l and NaCl is 83g / l. The decomposed solution is cooled to 40°C by water cooling and then enters the cold crystallizer. The decomposed liquid exchanges heat with the refrigerant in the cold crystallizer to cool down to 5°C, and the decahydrate and sesquibase that have been precipitated after thickening are taken out for solid-liquid separation. After dehydration and calcination of the separated crystals, 172 kilograms of heavy soda ash can be obtained, which can increase the output by 8.6%, of which Na 2 CO 3 The content is 99.3%, the NaCl content is 0.52%, and the bulk density is 0.96g / ml; the liquid separated by the centrifuge is about 1850 liters, of which NaCl 2 CO 3 88g / l, NaHCO 3 It is 4g / l, NaCl is 89g / l, and the liquid is recycled into the mother li...

Embodiment 3

[0071] Decomposition liquid evaporation method to prepare Na 2 CO 3 :

[0072] 2,000 liters of 80°C decomposition liquid discharged from the steam direct calcination reactor, of which Na 2 CO 3 236g / l, NaHCO 3 is 2g / l and NaCl is 48g / l. At a temperature of 103°C, the decomposition liquid was evaporated in a multi-effect evaporator until the volume was reduced by half. Take out the feed liquid, then lower the temperature to 60°C, and use a centrifuge to separate solid and liquid. After the solid is dehydrated and calcined in a calciner, 298 kg of heavy soda ash can be obtained, which can increase the output of soda ash by 15%. where Na 2 CO 3 Heavy soda ash with a content of 99.1%, a NaCl content of 0.7%, and a bulk density of 0.93g / ml; the separated liquid is about 800 liters, of which Na 2 CO 3 The content is 265g / l and the NaCl is 125g / l. The liquid is subjected to cold analysis or CO 2 Further recovery of NaHCO by carbonation 3 and Na 2 CO 3 , and then enter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com