Cold-resistant self-sticking emulsion product, and its production method and use

A self-adhesive, latex technology, applied in adhesive types, ester copolymer adhesives, etc., can solve problems such as insufficient adhesion, unsafe cost of oil-based adhesives, poor water resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

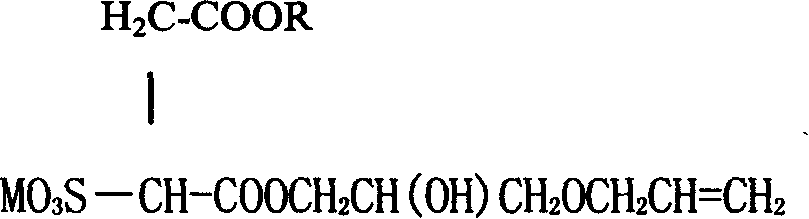

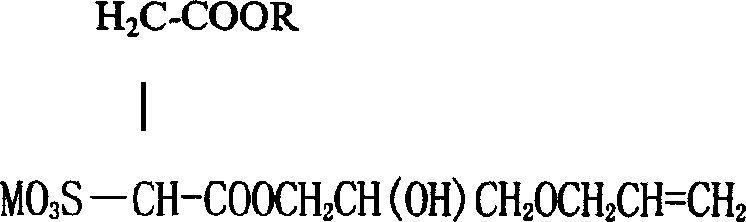

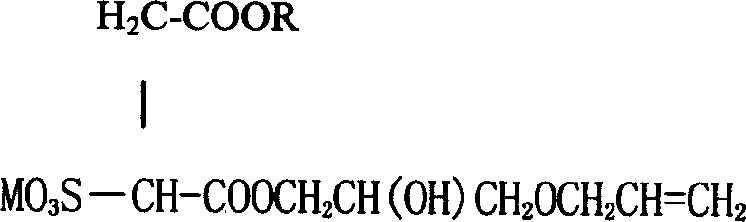

Method used

Image

Examples

Embodiment 1

[0080] Embodiment 1 Prepare 1# cold-resistant self-adhesive latex as follows:

[0081] (1) First put 400Kg octyl acrylate and 0.5Kg benzoyl peroxide into the stainless steel tank of the fast stirring emulsifying machine to dissolve;

[0082] (2) 10Kg solid content is 100% natural rosin denatured phenolic resin R-100 and puts into the stainless steel tank of the fast stirring emulsifying machine and immerses in dissolving;

[0083] (3) Stir and dissolve the natural rosin denatured phenolic resin with a 3600 R.P.M fast stirring emulsifier, take a sample after about 30 minutes, clamp the test solution with 2 transparent glass test pieces, check whether the solution is completely dissolved, until it is completely dissolved and there are no particles;

[0084] (4) Put 10Kg of reactive emulsifier ELEMINOL JS-2 with a solid content of 40%, and then stir it with a 3600 R.P.M fast mixer for 30 minutes, then take a sample and clamp the test solution with a transparent glass test piece t...

Embodiment 2

[0089] Embodiment 2 Prepare 2# cold-resistant self-adhesive latex as follows:

[0090] (1) First put 500Kg octyl acrylate and 0.75Kg benzoyl peroxide into the stainless steel tank of the fast stirring emulsifying machine to dissolve;

[0091] (2) Put 15Kg of reactive emulsifier LATEMUL S-180 with a solid content of 40%, and then stir it with a 3600 R.P.M fast mixer for 30 minutes, then take a sample and clamp the test solution with a transparent glass test piece to check whether it is completely emulsified Uniformly until there are no particles;

[0092] (3) Put 5Kg of methyl methacrylate, 5Kg of methacrylic acid, 25Kg of acrylic acid and 155Kg of pure water into a stainless steel bucket to mix with the emulsion formed in the previous steps, then stir with a 3600 R.P.M fast stirring emulsifier for 30 minutes and then take a sample for inspection Whether it is uniform, store it in the middle tank after being uniform, and prepare for the dropping point;

[0093] (4) Put 2Kg of...

Embodiment 3

[0096] Embodiment 3 Prepare 3# cold-resistant self-adhesive latex as follows:

[0097] (1) Put 300Kg butyl acrylate into the stainless steel barrel of the fast stirring emulsifying machine to dissolve;

[0098] (2) 30Kg of natural rosin modified phenolic resin Tamanole-102 with a solid content of 50% is put into the stainless steel barrel of a fast stirring emulsifying machine and immersed in it for dissolution;

[0099] (3) Stir and dissolve the natural rosin denatured phenolic resin with a 3600 R.P.M fast stirring emulsifier, take a sample after about 30 minutes, clamp the test solution with 2 transparent glass test pieces, check whether the solution is completely dissolved, until it is completely dissolved and there are no particles;

[0100] (4) Put 8Kg of reactive emulsifier LATEMUL S-180A with a solid content of 40%, and then stir it with a 3600 R.P.M fast mixer for 30 minutes, then take a sample and clamp the test solution with a transparent glass test piece to check wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com