Method for producing semiconductor device

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of high temperature, decrease in electrostatic capacitance of capacitive elements, increase in leakage current of capacitive elements, etc., and achieve high electrostatic capacitance. , to achieve the effect of electrostatic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

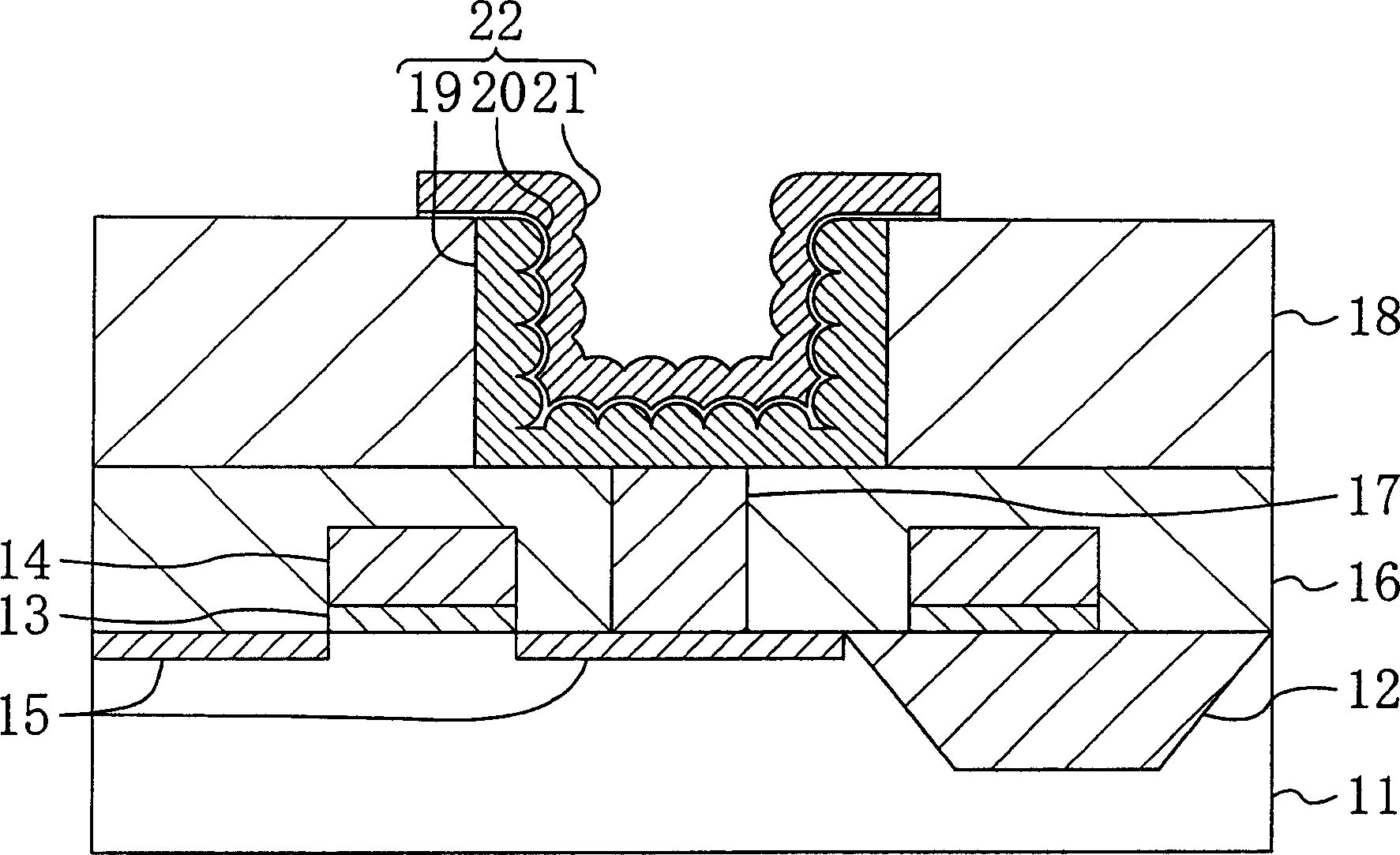

[0080] figure 1 The cross-sectional structure of the main part of the semiconductor device having the capacitor element according to the first embodiment of the present invention is shown. like figure 1 As shown, a semiconductor substrate 11 made of silicon (Si) is divided into element formation regions by an element isolation insulating film 12, and in the divided element formation regions, a gate electrode 14 with a gate insulating film 13 interposed therebetween is formed on the semiconductor substrate. The gate electrodes 14 in the regions on both sides of the gate electrode 14 in 11 constitute an access transistor.

[0081] A first interlayer insulating film 16 is formed on the semiconductor substrate 11 so as to cover the gate electrode 14 and the upper surface is planarized, and a source / drain region 15 of the first interlayer insulating film 16 is formed over one side of the source / drain region 15 and made of conductive polycrystalline silicon. contact plug 17.

...

Embodiment 2

[0111] Next, Embodiment 2 of the present invention will be described with reference to the accompanying drawings.

[0112] Figure 4 A cross-sectional structure of a main part of a semiconductor device having a capacitor element according to Embodiment 2 of the present invention is shown. exist Figure 4 , by for and figure 1 The same constituent members as shown are assigned the same reference numerals, and the description thereof will be omitted.

[0113] Example 2 is different from Example 1 in that the structure of the interface layer between the lower electrode 19 and the capacitor insulating film 20 is different, so a method for manufacturing the capacitor element 22 will be described.

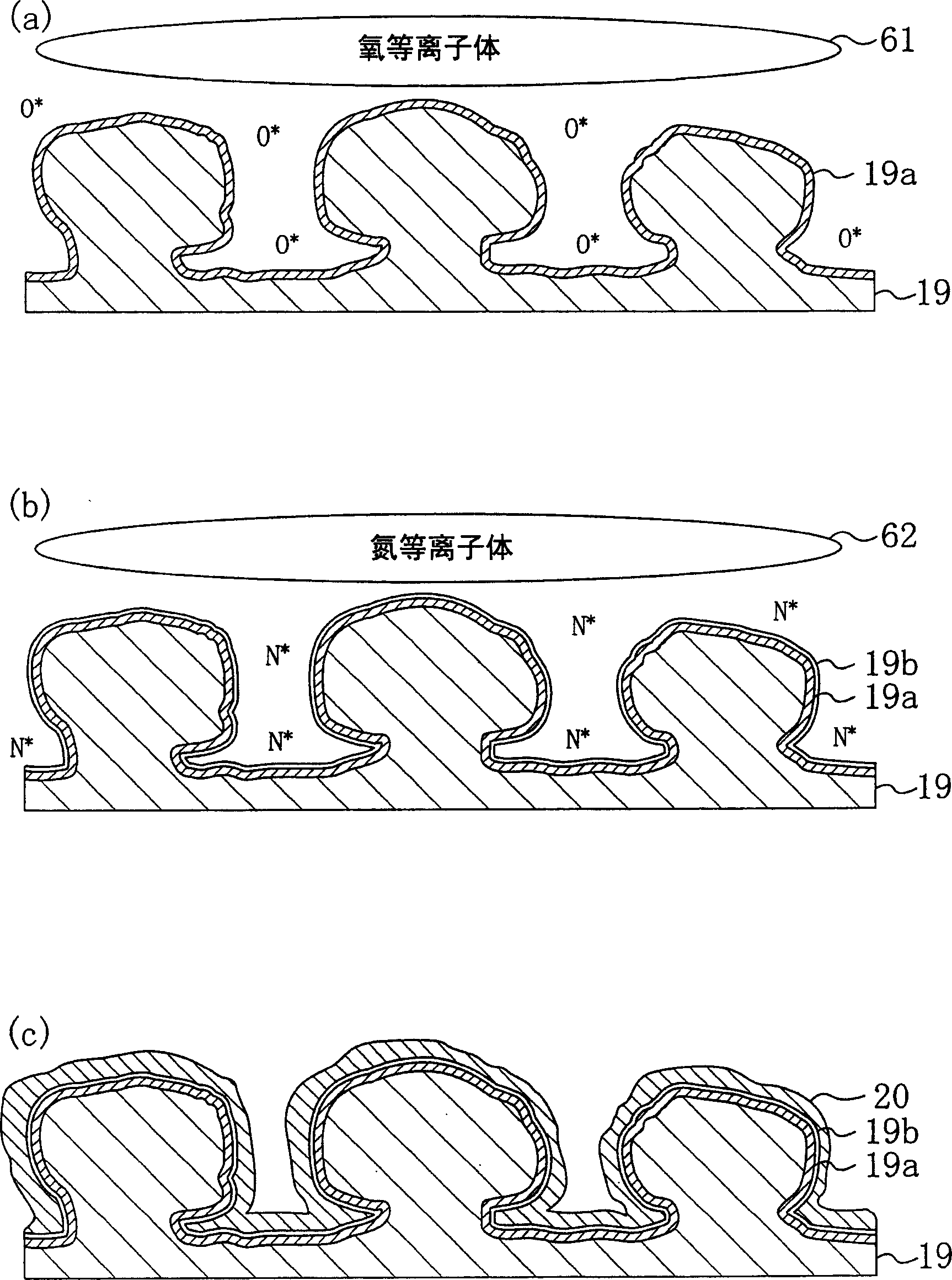

[0114] Figure 5 (a) to (c) and Image 6 (a) and (b) are the manufacturing method of the semiconductor device according to the second embodiment of the present invention, that is, part of the amplifying capacitive element, and show the cross-sectional structure of the sequence of s...

Embodiment 3

[0137] Next, Embodiment 3 of the present invention will be described with reference to the accompanying drawings.

[0138] Figure 7 A cross-sectional structure of a main part of a semiconductor device having a capacitor element according to Embodiment 3 of the present invention is shown. exist Figure 7 , for and figure 1 The same constituent members as shown are assigned the same reference numerals, and the description thereof will be omitted.

[0139] Example 3 is different from Example 1 in that the capacitor insulating film 20 has a laminated structure, and therefore, a method for manufacturing the capacitor element 22 will be described.

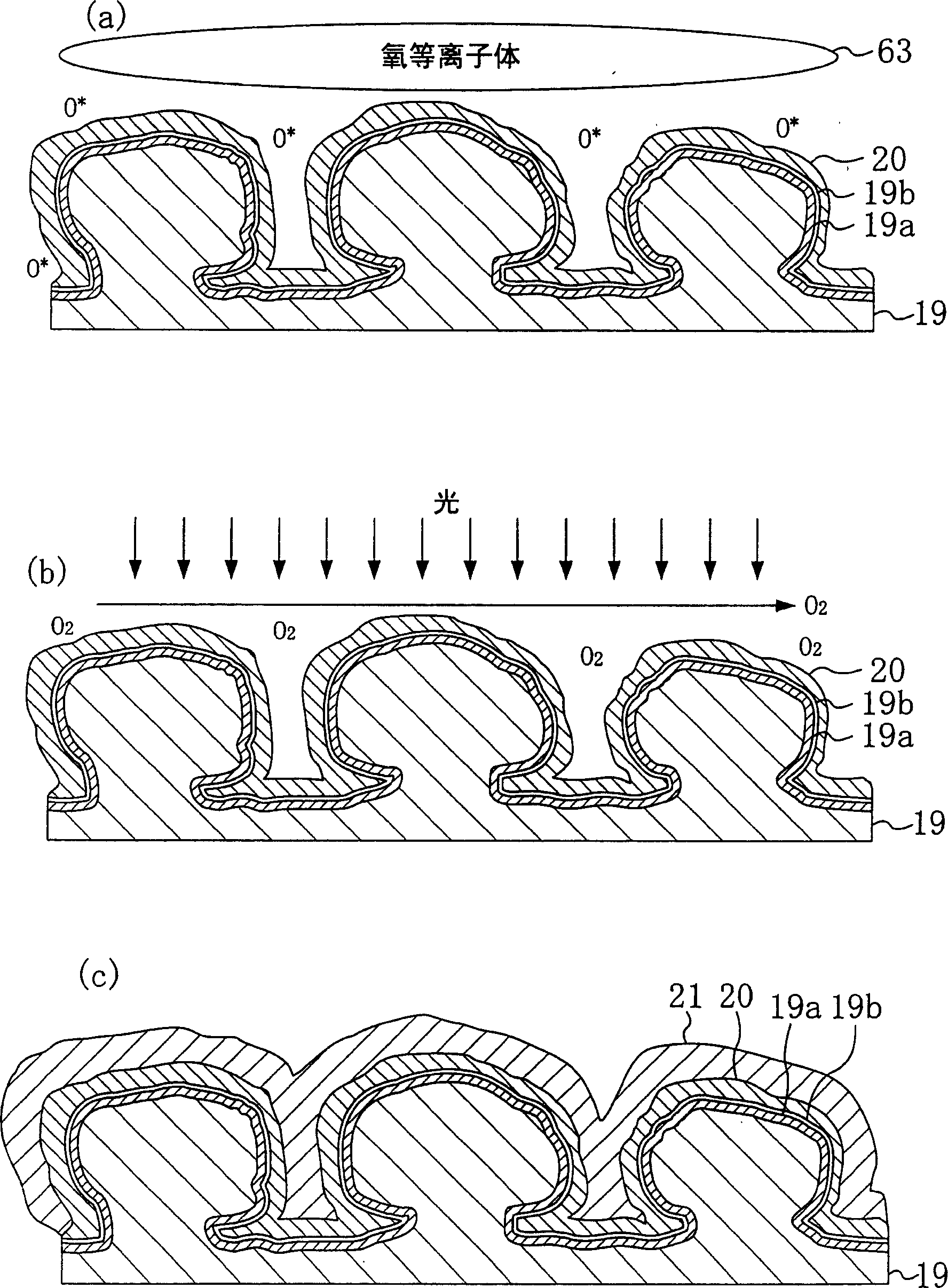

[0140] Figure 8 (a)~(d), Figure 9 (a) to (c) are cross-sectional structures showing the order of steps of a part of the manufacturing method of the semiconductor device according to Embodiment 3 of the present invention, that is, a part of the amplifying capacitive element.

[0141] First, the lower electrode 19 made of polycry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com