Synthesis method of monodispersed nano-mesopore silicon dioxide material

A nano-mesoporous, silica technology, applied in chemical instruments and methods, molecular sieves and base exchange compounds, inorganic chemistry, etc., can solve the problems of aggregates affecting performance and application, restricting applications, easy agglomeration, etc., to achieve orderly Good performance, high specific surface area, high specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 6.0g of hexadecyltrimethylammonium bromide and 10.56g of F127 (PEO-PPO-PEO, average molecular weight 11000) in 600g of ammonia solution (36.96g of ammonia water), fully stir at 35°C, and wait until After the surfactant is completely dissolved, add 20g of tetraethyl orthosilicate, stir continuously at room temperature for 2 hours to obtain a transparent sol, transfer it to a constant temperature drying oven, dry the water at 100°C to obtain a white powder, and roast at a high temperature of 550°C for 6 hours. The final monodisperse nanometer mesoporous silica material is obtained.

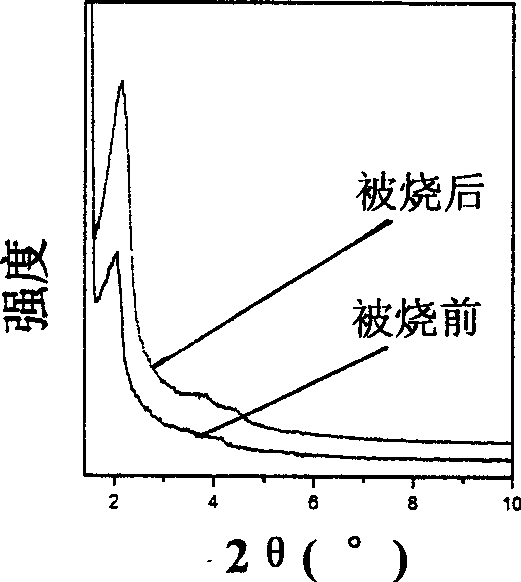

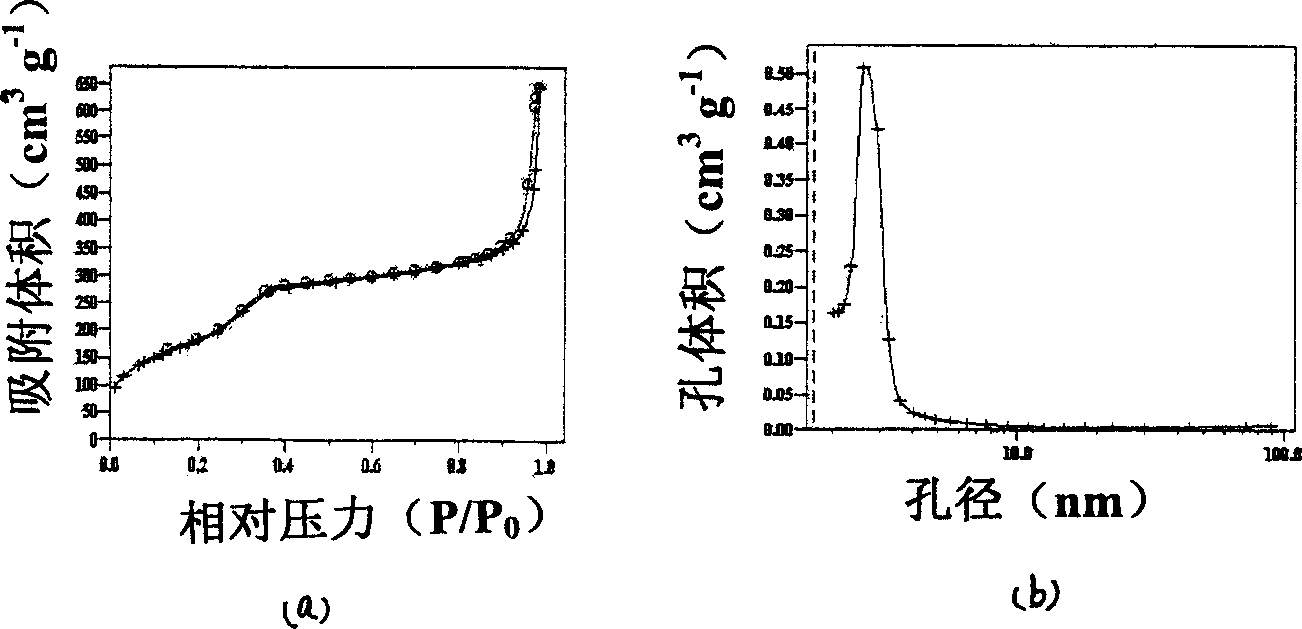

[0025] figure 1 (b) is the particle transmission electron microscope photo of the sample. The transmission electron microscope photo shows monodisperse uniform spherical particles with a particle size of 70-80nm, and the XRD spectrum shows an ordered hexagonal mesoporous structure. image 3 (a) and image 3 (b) is the nitrogen adsorption-desorption curve and the pore distribution c...

Embodiment 2

[0027] Dissolve 5.2g of dodecyltrimethylammonium bromide and 10.56g of F127 (PEO-PPO-PEO, average molecular weight 11000) in 600g of ammonia solution (61.60g of ammonia water), fully stir at 30°C, and wait until After the surfactant is completely dissolved, add 20g of tetraethyl orthosilicate, stir continuously at 30°C for 4 hours to obtain a transparent sol, transfer it to a constant temperature drying oven, dry the water at 80°C to obtain a white powder, and roast at 550°C for 6 hours , to obtain the final monodisperse nanometer mesoporous silica material.

[0028] The transmission electron microscope photos show monodisperse uniform spherical particles with a particle size of about 100nm, the XRD spectrum shows an ordered hexagonal mesoporous structure, the nitrogen adsorption and desorption spectrum shows a mesoporous structure with uniform pore size distribution, and the specific surface area is 900m 2 / g or so, the pore size is 2-3nm.

Embodiment 3

[0030] Dissolve 6.0g cetyltrimethylammonium bromide and 5.28g F127 (PEO-PPO-PEO, average molecular weight 11000) in 1500g sodium hydroxide solution (2M sodium hydroxide 14.5ml), at 80°C Stir thoroughly, after the surfactant is completely dissolved, add 20g of tetraethyl orthosilicate, and stir continuously at 40°C for 1 hour to obtain a transparent sol, transfer it to a constant temperature drying oven, dry the water at 80°C to obtain a white powder, and store at 550°C Calcined at high temperature for 10 hours to obtain the final monodisperse nanometer mesoporous silica material.

[0031] figure 1 (a) is the transmission electron microscope photo of the particle, the transmission electron microscope photo shows monodisperse uniform spherical particles with a particle size of 50-60nm, the XRD spectrum shows an ordered hexagonal mesoporous structure, and the nitrogen adsorption and desorption spectrum shows the pore size Uniformly distributed mesoporous structure with a specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com