Method for analyzing composition of alcohol-containing gasoline and alcohol adsorption material used thereby

An adsorption material and gasoline technology, which is applied in the field of analyzing the composition of alcohol-containing gasoline, and can solve problems such as complex operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

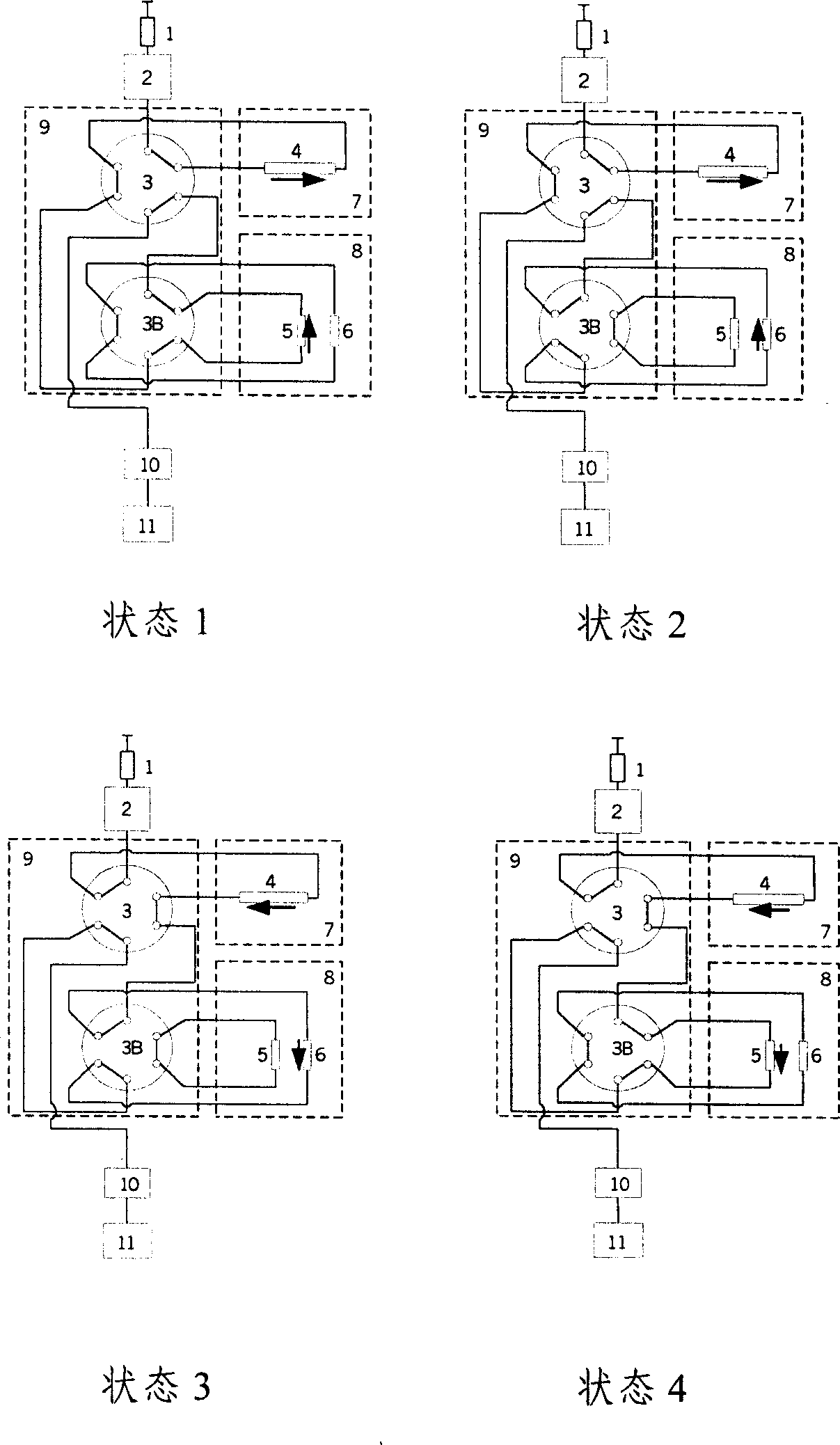

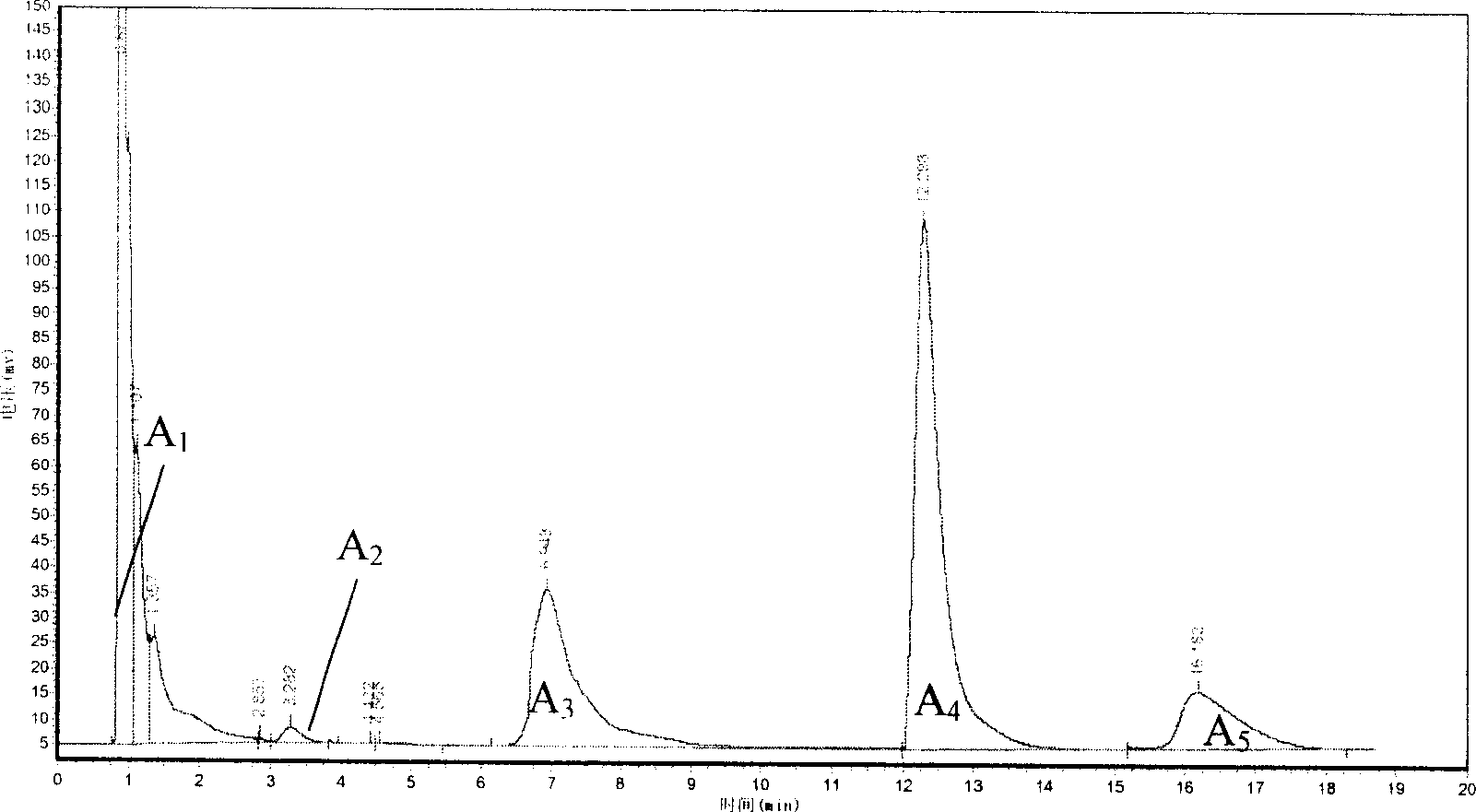

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the alcohol adsorption material of the present invention is: mix diatomite powder with an appropriate amount of water, the mass ratio of water to diatomite is 0.5-6.5:1, stir evenly, and make block or other shapes, such as making Form into pellets, strips, granules, and then dry at a temperature of 20-120°C. After drying, it is calcined at 500-1000°C, preferably 600-900°C. The calcined block diatomite is pulverized into particles of 0.18-0.30 mm to obtain the carrier.

[0021] The above carrier is impregnated with anhydrous calcium chloride aqueous solution, the impregnation temperature is 20-100°C, preferably 20-50°C, the time is preferably 0.5-3.0 hours, the concentration of the calcium chloride aqueous solution used for impregnation is 1.0-40% by mass, during impregnation The liquid / solid volume ratio of the impregnation liquid to the carrier is 0.9-2.0:1, preferably 0.9-1.2:1. After impregnation, the solid is dried at 80-180° C. for prefe...

example 1

[0031] Preparation of the support for the alcohol trap used in the method of the invention.

[0032] Mix diatomite raw ore powder (produced by Shanwang Chemical Co., Ltd. in Linqu, Shandong) and deionized water at a mass ratio of 1:1, dry at 110°C for 5 hours, roast at 900°C for 7 hours, and place in the deionized water while it is hot. Cool in sub water. Filter, dry at 110°C for 5 hours, pulverize with a ball mill, sieve into particles of 0.18-0.3 mm, wash with deionized water until no powder appears, and dry at 120°C for 5 hours to obtain carrier Z 1 , and its physical and chemical properties are listed in Table 1. The pore diameter, pore volume, and pore distribution in Table 1 were measured by mercury intrusion porosimetry, and the specific surface area was measured by low-temperature nitrogen adsorption method.

example 2

[0034] Prepare carrier Z by the method for example 1 2 , the difference is that the calcination temperature is 950°C, and the prepared carrier Z 2 The physical and chemical properties are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com