Method for producing low molecular polyamide from tung oi

A low-molecular polyamide and tung oil technology, which is applied in the field of low-molecular polyamide prepared from tung oil, can solve the problems of unsatisfactory mechanical properties of tensile strength and tensile shear strength, low heat distortion temperature, low hardness, etc., and achieve good mechanical properties. Effects of performance, consumption reduction, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of Methyl Caryonate

[0025] In a 500ml three-neck flask equipped with a constant temperature oil bath, a stirring device, a thermometer, and a reflux condenser, add 298 grams of tung oil, heat to 120 ° C, dehydrate under reduced pressure for 1 to 2 hours, cool to 50 ° C, add 260 grams of methanol, 5 gram of potassium hydroxide, reacted at 60-70°C for 4 hours, recovered excess methanol, and cooled to room temperature. Glycerol was separated, and after washing to remove the catalyst, free water was distilled off to obtain 280 grams of methyl lyceate.

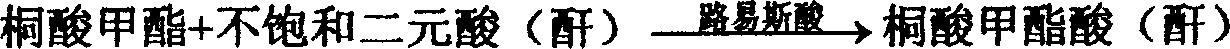

[0026] (2) Preparation of Methyl Caryonate Anhydride Adduct

[0027] In a 500ml three-necked flask equipped with a constant temperature oil bath, a stirring device, a thermometer, and a distillation device, add 298 grams of methyl laurate, 120 grams of maleic anhydride, and 8.5 grams of aluminum trichloride, and heat to 80°C. After -9 hours, the unreacted maleic anhydride was distilled off under negative ...

Embodiment 2

[0031] (1) Preparation of Methyl Caryonate

[0032] In a 500ml three-neck flask equipped with a constant temperature oil bath, a stirring device, a thermometer, and a reflux condenser, add 298 grams of tung oil, heat to 120 ° C, dehydrate under reduced pressure for 1 to 2 hours, cool to 50 ° C, add 260 grams of methanol, 5 gram of potassium hydroxide, reacted at 60-70°C for 4 hours, recovered excess methanol, and cooled to room temperature. Glycerol was separated, and after washing to remove the catalyst, free water was distilled off to obtain 280 grams of methyl lyceate.

[0033] (2) Preparation of Methyl Caryonate Acid (Anhydride) Adduct

[0034] In a 500ml three-necked flask equipped with a constant temperature oil bath, a stirring device, a thermometer, and a distillation device, add 298 grams of methyl laurate, 120 grams of maleic anhydride, and 8.5 grams of aluminum trichloride, and heat to 80°C. After -9 hours, the unreacted maleic anhydride was distilled off under ne...

Embodiment 3

[0038] (1) Preparation of Methyl Caryonate

[0039] In a 500ml three-neck flask equipped with a constant temperature oil bath, a stirring device, a thermometer, and a reflux condenser, add 298 grams of tung oil, heat to 120 ° C, dehydrate under reduced pressure for 1 to 2 hours, cool to 50 ° C, add 260 grams of methanol, 5 gram of potassium hydroxide, reacted at 60-70°C for 4 hours, recovered excess methanol, and cooled to room temperature. Glycerol was separated, and after washing to remove the catalyst, free water was distilled off to obtain 280 grams of methyl lyceate.

[0040] (2) Preparation of Methyl Caryonate Acid (Anhydride) Adduct

[0041] In a 500ml three-necked flask equipped with a constant temperature oil bath, a stirring device, a thermometer, and a distillation device, add 298 grams of methyl laurate, 120 grams of maleic anhydride, and 8.5 grams of aluminum trichloride, and heat to 80°C. After -9 hours, the unreacted maleic anhydride was distilled off under ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com