Process for extracting alantin

An extraction process, the technology of inulin, applied in the field of inulin extraction process, can solve the problems of regular replacement, difficult storage, high production cost, etc., and achieve the effect of improving taste, not easy to agglomerate and clot, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

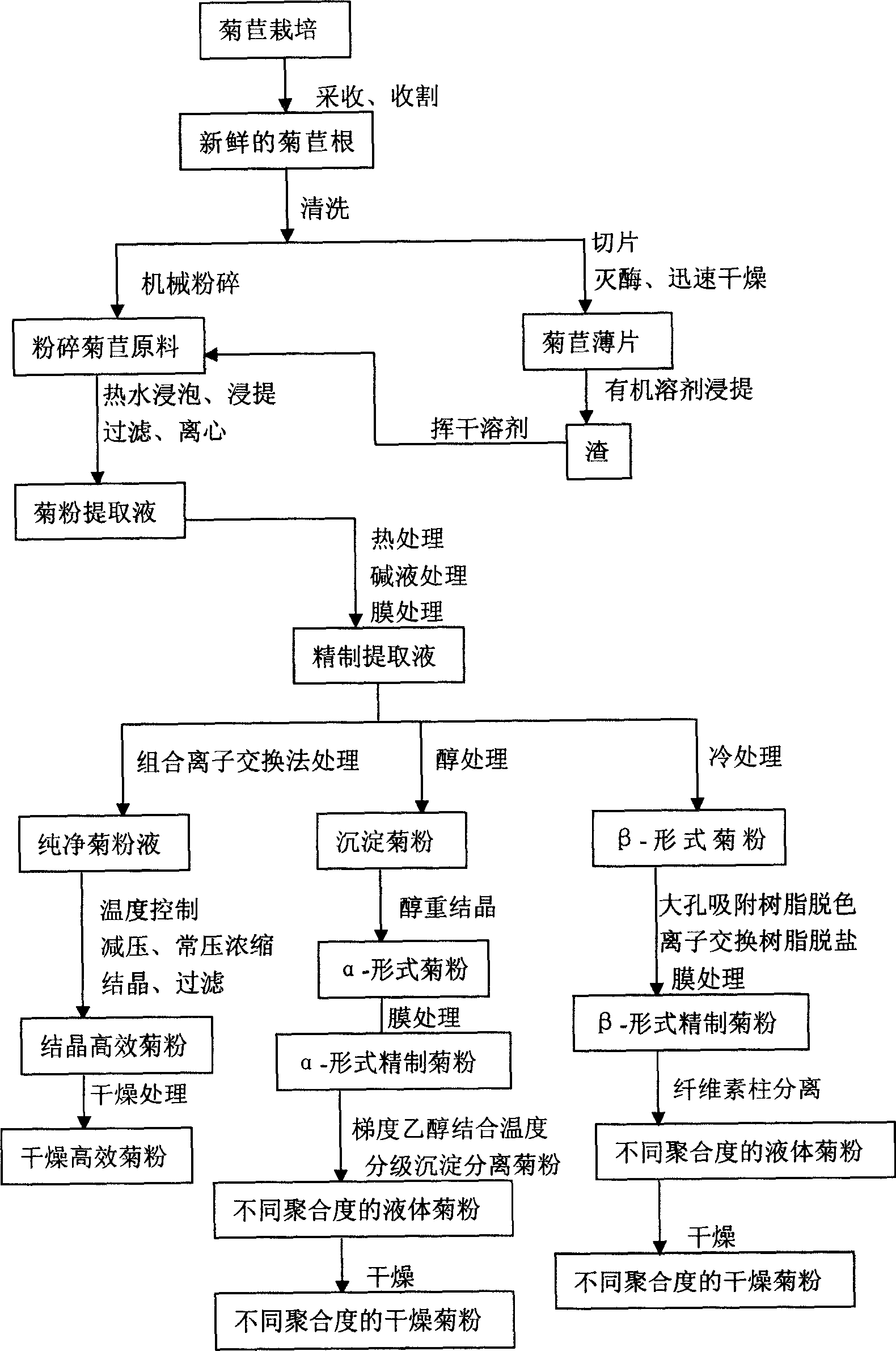

Method used

Image

Examples

preparation example Construction

[0047] (2) Preparation of α-form inulin: long-chain inulin can be precipitated and filtered out in high-concentration organic solvents. The organic solvents are preferably ethanol, methanol, and isopropanol. The method is to concentrate the water extract rich in inulin to less than 1 / 2 of the original extract, then add 1-5 times the amount of 95% alcohol (V / V), after adding the alcohol, the alcohol content of the solution is not less than 60 % (V / V), let stand for 2-5h, suction filtration or centrifugation, recover the alcohol from the solution, dissolve the precipitate with a small amount of water, recrystallize the alcohol several times, evaporate the solvent to obtain α-form inulin. Inulin obtained by this method is not as soluble in cold water as the β-form of inulin.

[0048] (3) β-form inulin: β-form inulin can be obtained by directly cooling the inulin extract at 0-3°C for 24-48 hours, and collecting the precipitate; a small amount of inulin seeds can be added during th...

Embodiment 1

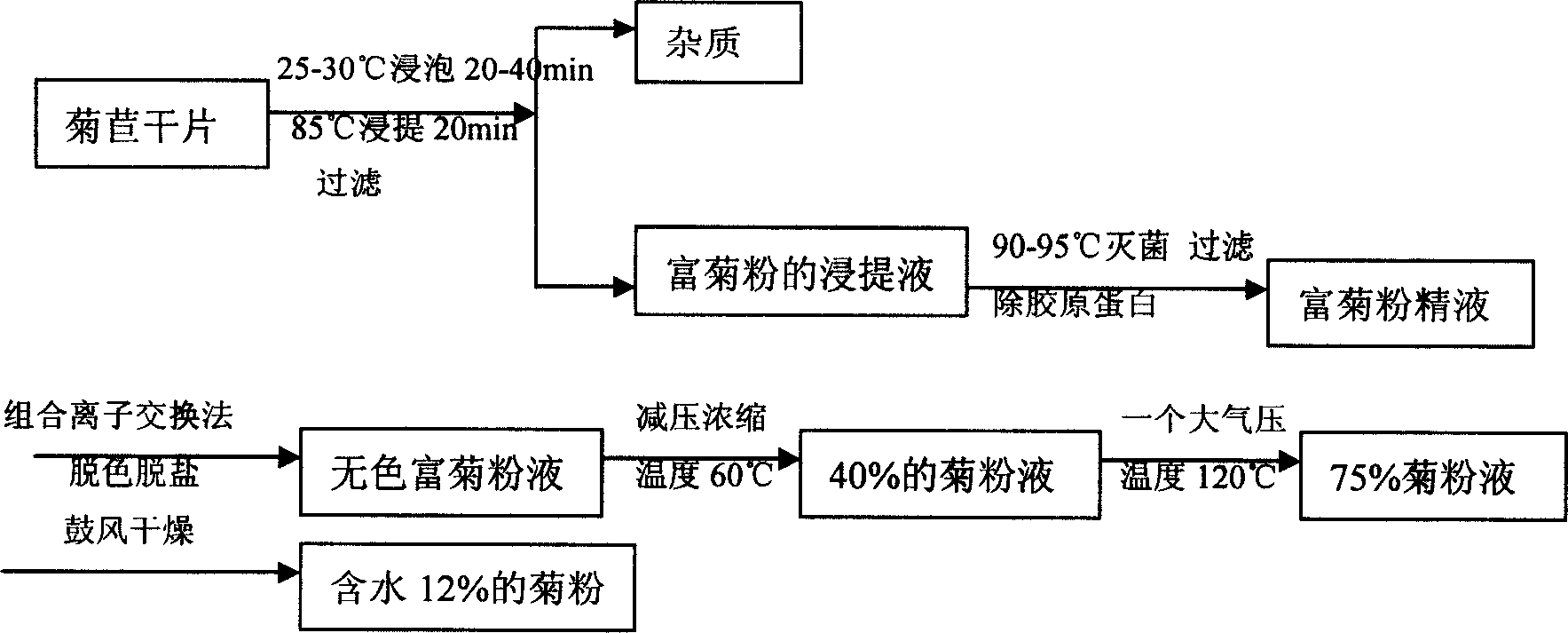

[0064] Embodiment 1: produce efficient inulin

[0065] see figure 210kg dried chicory root slices were soaked at 25-30°C for 20-40min, extracted at 85°C, filtered to remove impurities, sterilized at 90-95°C, filtered to remove collagen, and rich The inulin-containing semen is decolorized and desalted with strong acid resin, strong basic resin and weak acid resin combined ion exchange method to obtain a colorless and transparent inulin-rich liquid, which is quickly concentrated under reduced pressure at a temperature of 60°C. When the inulin concentration reaches 40%, it can be stopped, and it is immediately subjected to the second stage of processing: normal pressure, 120°C, rapid concentration, and stops when the inulin concentration reaches 75%. The obtained inulin polymerization degree DP of 10-40 accounts for 75% at this moment. This inulin liquid was dried by blast drying method to obtain 4.324 kg of inulin with a water content of 12%.

Embodiment 2

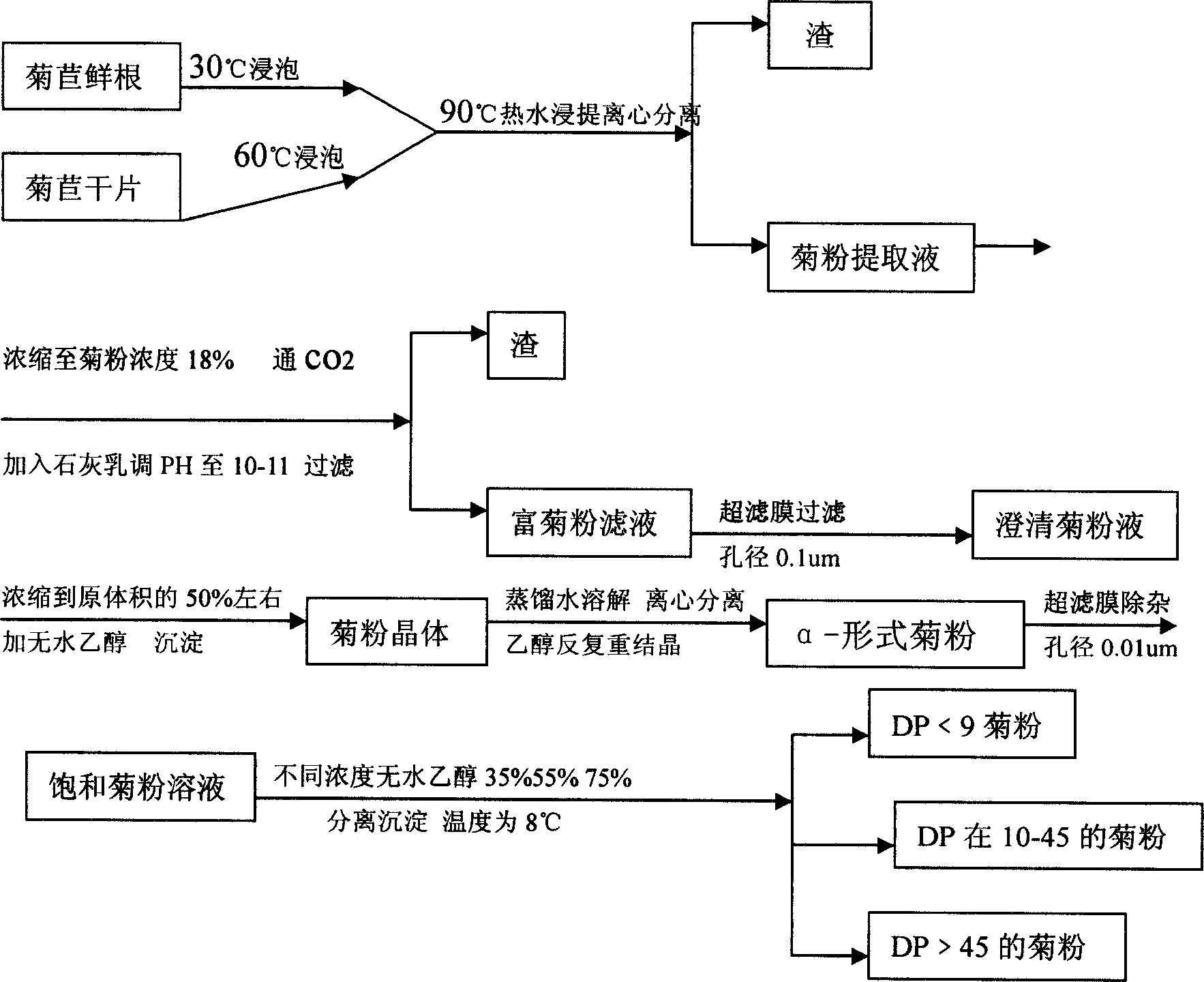

[0066] Example 2: Preparation and separation of α-form inulin

[0067] See the specific process image 3 10kg of fresh chicory root, soaked at 30°C for 20min, or 10kg of dry chicory root slices, soaked at 60°C for 30min and mixed, then heated to 90°C for hot water extraction, centrifuged, and the residue was removed to obtain an inulin extract, and the above-mentioned inulin was extracted Liquid concentrated to inulin concentration 18%, through co 2 Add milk of lime to adjust the pH to 10-11, filter and discard the residue to obtain the inulin-rich filtrate, filter through an ultrafiltration membrane (pore size 0.1 μm) to obtain a clarified inulin liquid, and then concentrate it to about 50% of the original volume. Precipitate with water and ethanol to obtain inulin crystals; dissolve in distilled water, centrifuge and separate ethanol for repeated crystallization to obtain α-form inulin, and remove impurities from the α-form inulin ultrafiltration membrane (pore size 0.01 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com