Method for synthesizing LiCoxMn2-xO4 as anode material of lithium-ion secondary battery

A technology for secondary batteries and positive electrode materials, applied in battery electrodes, electrode manufacturing, electrode heat treatment, etc., can solve problems such as poor cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

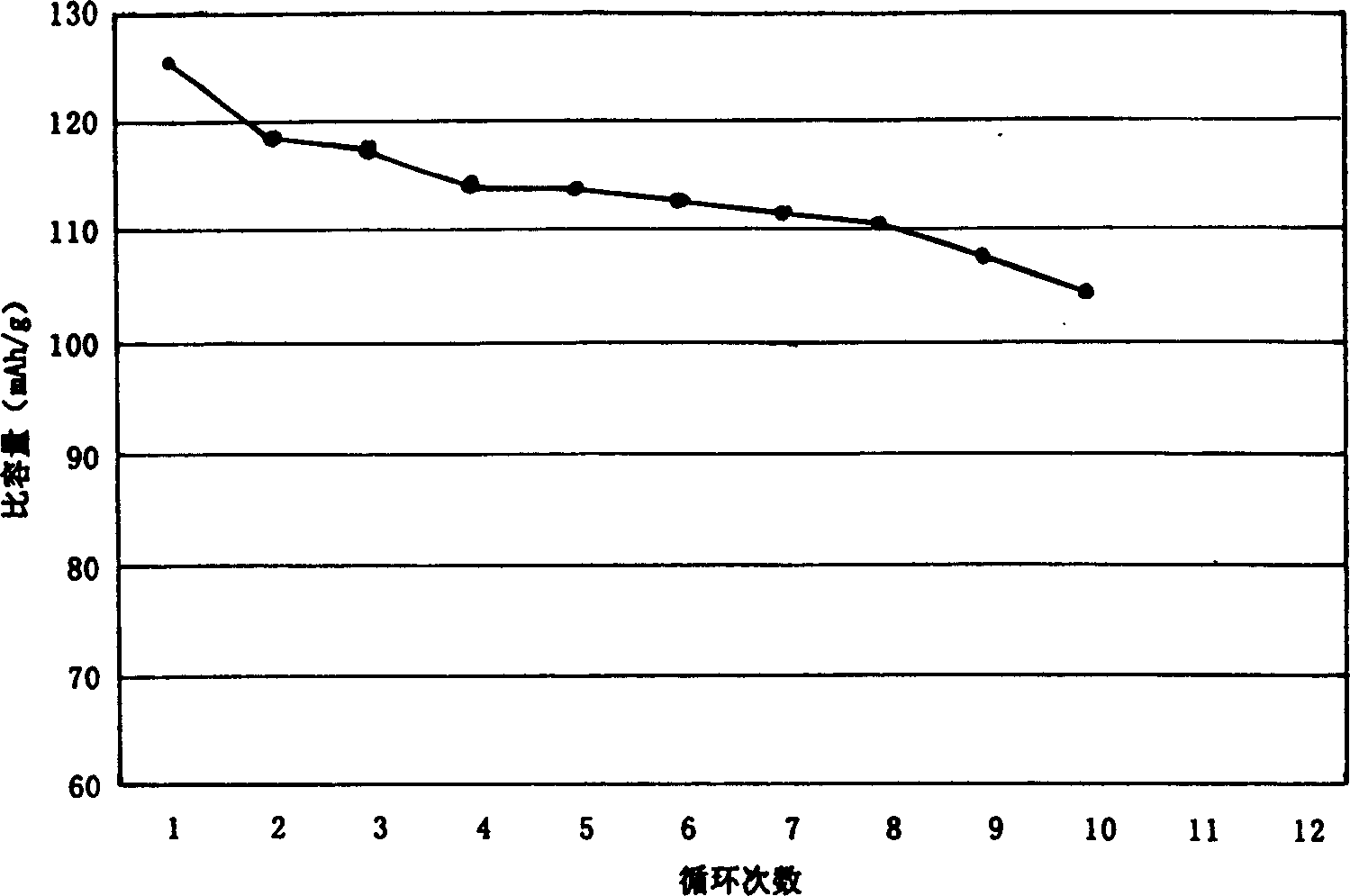

Embodiment 1

[0014] LiOH-H 2 O and manganese dioxide are mixed according to the ratio of Li:Mn=1:2 (atomic ratio), the mixture is put into a crucible, placed in flowing air at 450°C for 9 hours, ground after cooling, and then heated at 800°C Keep warm for 30 hours, grind and sieve the product and make a battery according to the above ratio for charge and discharge test. The voltage range is 4.20-3.15V, and the charge and discharge rate is 0.5C. figure 1 Curves of specific capacity (mAh / g) versus cycle times.

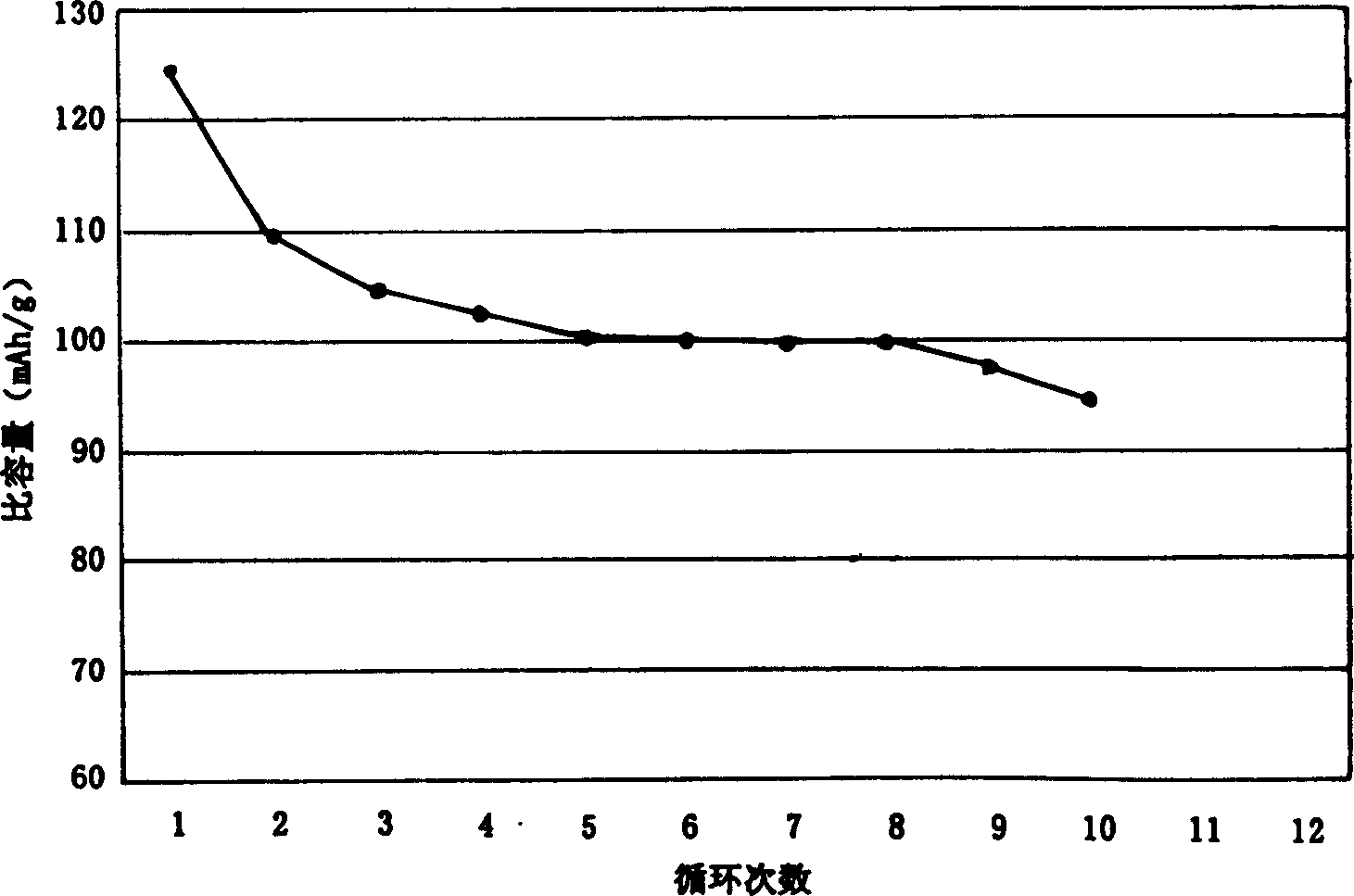

Embodiment 2

[0016] LiOH-H 2 O, electrolytic manganese dioxide (EMD) and Co 3 o 4 Mix according to the ratio of Li:Mn:Co=1:(2-x):x (atomic ratio), put the mixture into a crucible, pretreat it in flowing air at 450°C for 9 hours, grind it after cooling, and then put it in Keep warm at 800°C for 30 hours, grind and sieve the product and make a battery according to the above ratio for charge and discharge test. The voltage range is 4.20-3.15V, and the charge and discharge rate is 0.5C. figure 2 Curves of specific capacity (mAh / g) versus cycle times.

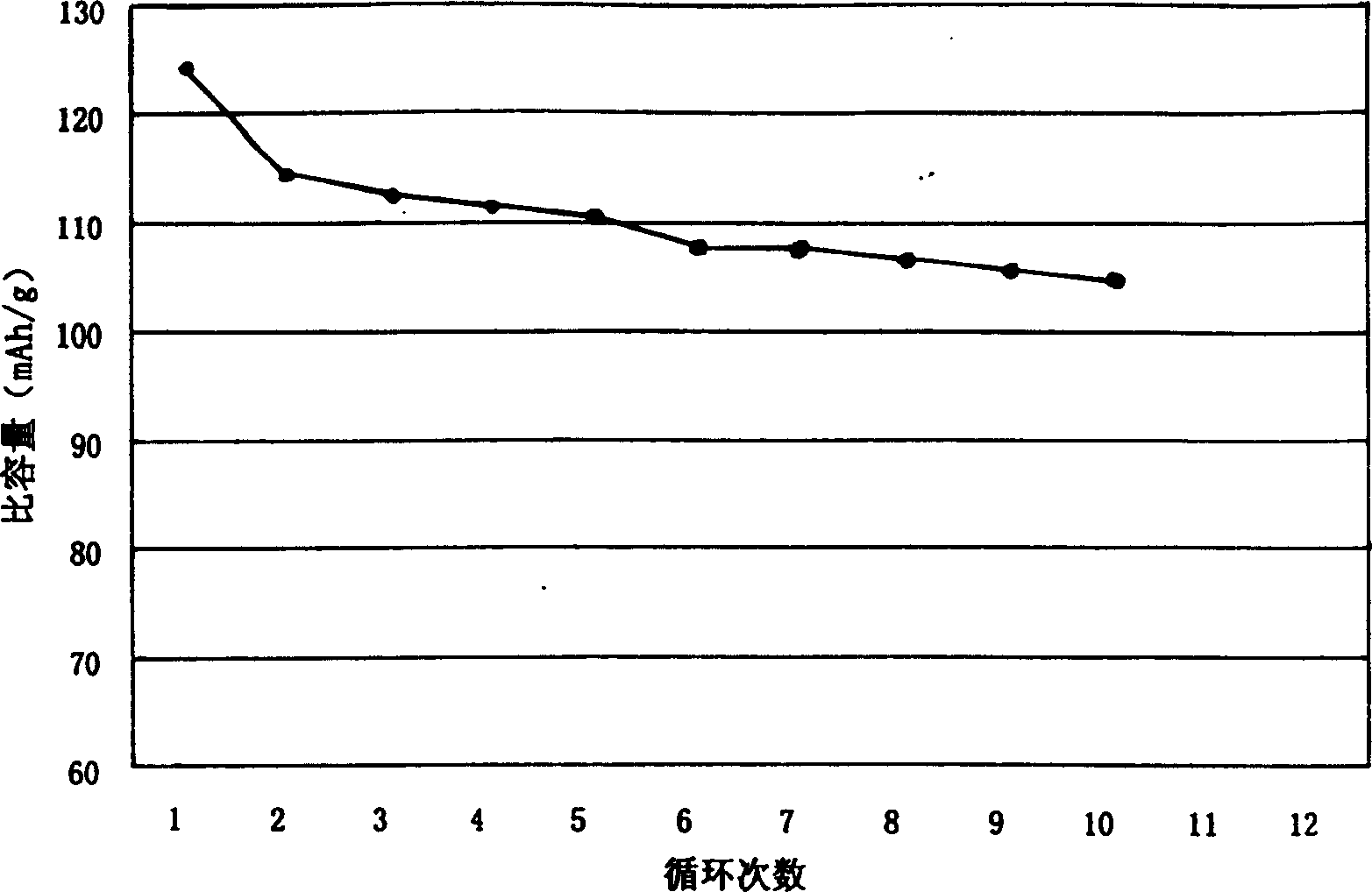

Embodiment 3

[0018] LiOH-H 2 O, manganese trioxide (Mn 2 o 3 ) and Co 3 o 4 Mix according to the ratio of Li:Mn:Co=1:(2-x):x (atomic ratio), put the mixture into a crucible, pretreat it in flowing air at 450°C for 9 hours, grind it after cooling, and then put it in Keep warm at 800°C for 30 hours, grind and sieve the product and make a battery according to the above ratio for charge and discharge test. The voltage range is 4.20-3.15V, and the charge and discharge rate is 0.5C. image 3 Curves of specific capacity (mAh / g) versus cycle times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com