Doped group III-V nitride materials, and microelectronic devices and device precursor structures comprising same

A technology of microelectronic device and device structure, applied in the field of doped III-V group nitride materials, can solve problems such as no satisfactory solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0129] δ-doped HEMT device structure

[0130] In hydrogen (H 2 ) under a pressure of 100 mbar in an environment, heating the sapphire substrate to 1170° C. for ten minutes. Keeping the pressure constant for the remainder of the delta-doped structure growth, the reactor was cooled to 500°C, and then a low-temperature aluminum nitride (AlN) nucleation buffer layer was deposited in a conventional manner. After the buffer layer is deposited on the sapphire substrate, in 2.5slm ammonia (NH 3 ) and 20slm hydrogen (H 2 ) to a susceptor temperature of 1220° C. and hold this temperature for 2 minutes.

[0131] Trimethylgallium (TMG) was introduced into the reactor at a flow rate sufficient to provide a growth rate of approximately 2.0 μm / hr for 90 minutes, thereby depositing a 3 μm thick gallium nitride (GaN) layer. Trimethylaluminum (TMA) was introduced for 5.5 seconds to grow aluminum gallium nitride (Al 0.25 Ga 0.75 N) Separate layer.

[0132] In the next step, the pre-susp...

example 2

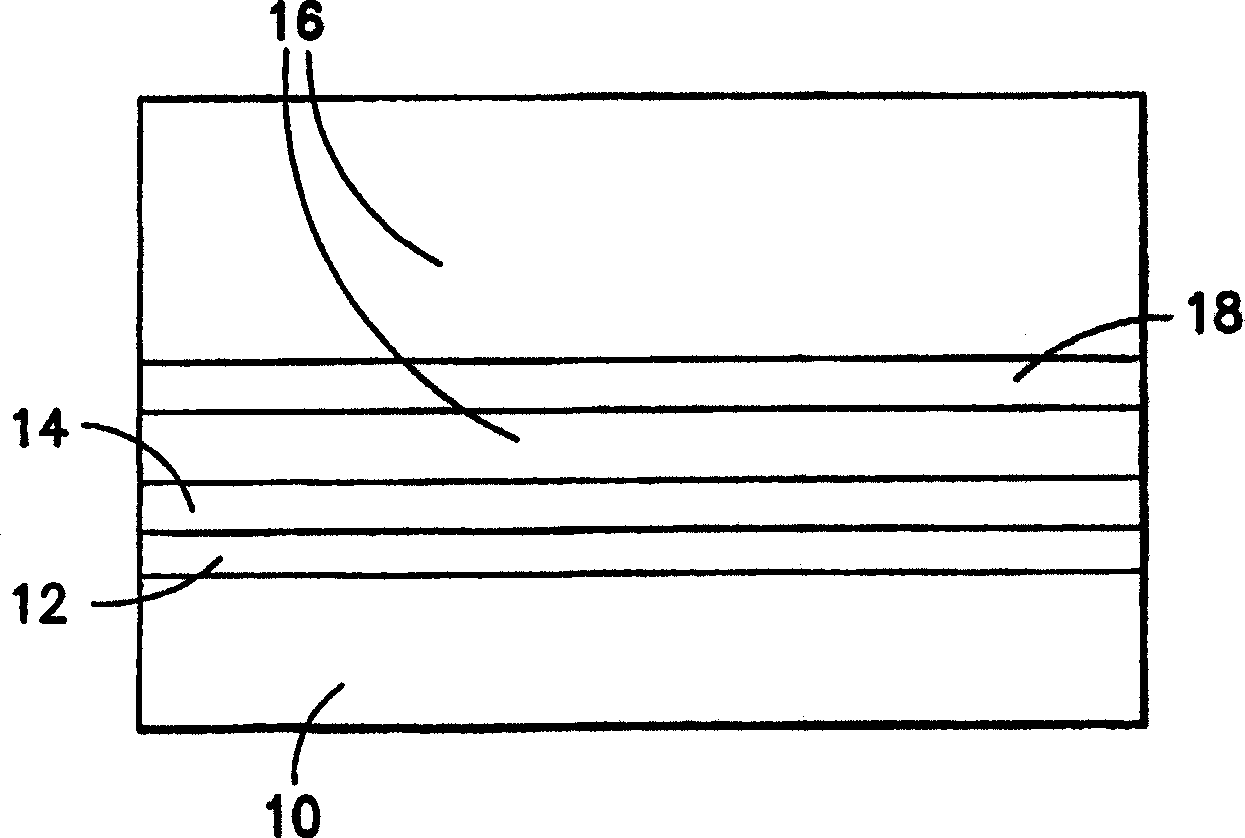

[0135] δ-doped superlattice structure

[0136] In hydrogen (H 2 ) under a pressure of 100 mbar in an environment, heating the sapphire substrate to 1170° C. for ten minutes. Keeping the pressure constant for the remainder of the delta-doped structure growth, the reactor was cooled to 500°C, and then a low-temperature aluminum nitride (AlN) nucleation buffer layer was deposited in a conventional manner. After the buffer layer is deposited on the sapphire substrate, in 2.5slm ammonia (NH 3 ) and 20slm hydrogen (H 2 ) to a susceptor temperature of 1220° C. and hold this temperature for 2 minutes.

[0137] Trimethylgallium (TMG) was introduced into the reactor at a suitable flow rate to provide a growth rate of approximately 2.0 μm / hr for 90 minutes, thereby depositing a 3 μm thick gallium nitride (GaN) layer. Trimethylaluminum (TMA) was introduced at an appropriate flow rate to grow AlGaN (Al 0.2 Ga 0.8 N) layer.

[0138] In the next step, the pre-suspension step was ini...

example 3

[0142] Photocathode structure

[0143] In hydrogen (H 2 ) environment and under a pressure of 100 mbar, the sapphire substrate was heated to 1170° C. for ten minutes. Keeping the pressure constant for the remainder of the delta-doped structure growth, the reactor was cooled to 500°C, and then a low-temperature aluminum nitride (AlN) nucleation buffer layer was deposited in a conventional manner. After the AlN buffer layer was deposited on the sapphire substrate, ammonia (NH 3 ) and hydrogen at a flow rate of 20slm (H 2 ) to a susceptor temperature of 1220° C. and hold this temperature for 2 minutes. Trimethylgallium (TMG) and trimethylaluminum (TMA) were introduced into the reactor to grow AlGaN (Al 0.3 Ga 0.7 N) layer. In the next step, the pre-suspension step was initiated by turning off TMG and TMA entering the reactor, placing the interface at a susceptor temperature of 1220 °C under ammonia gas (NH 3 ) and hydrogen (H 2 )Environment. Steps last 10 seconds befor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com