Assistant hot-pressed packing method for polymethylmethacrylate microflow controlled chip solvent

A polymethyl methacrylate, microfluidic chip technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of easy cracking of the chip, large deformation of the microfluidic channel, easy blockage, etc., and achieve the sample dosage. The effect of less, easy operation and high analysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

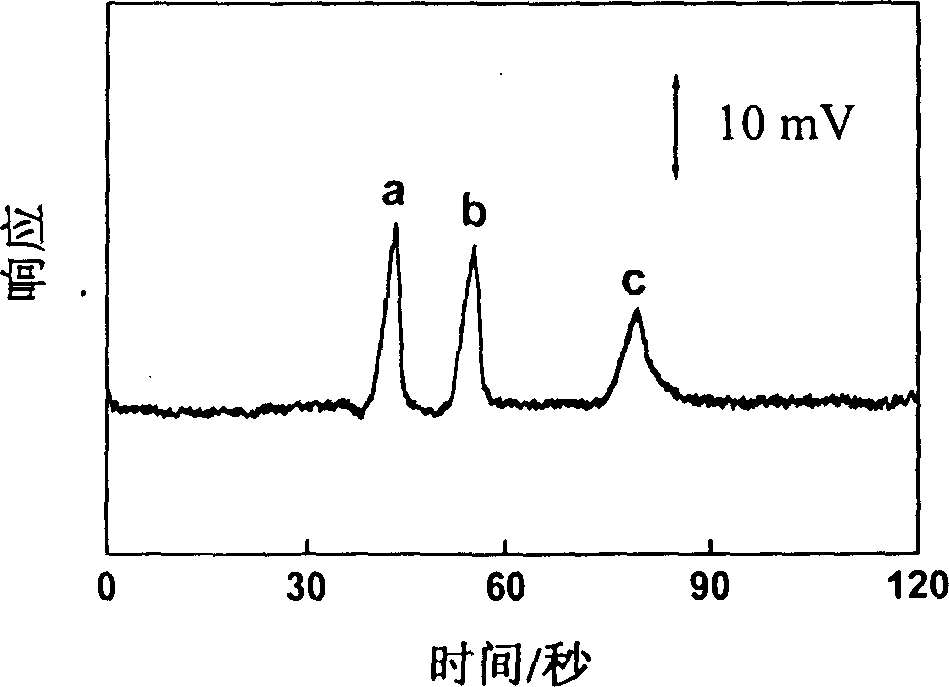

[0021] Further describe the present invention below by embodiment and accompanying drawing:

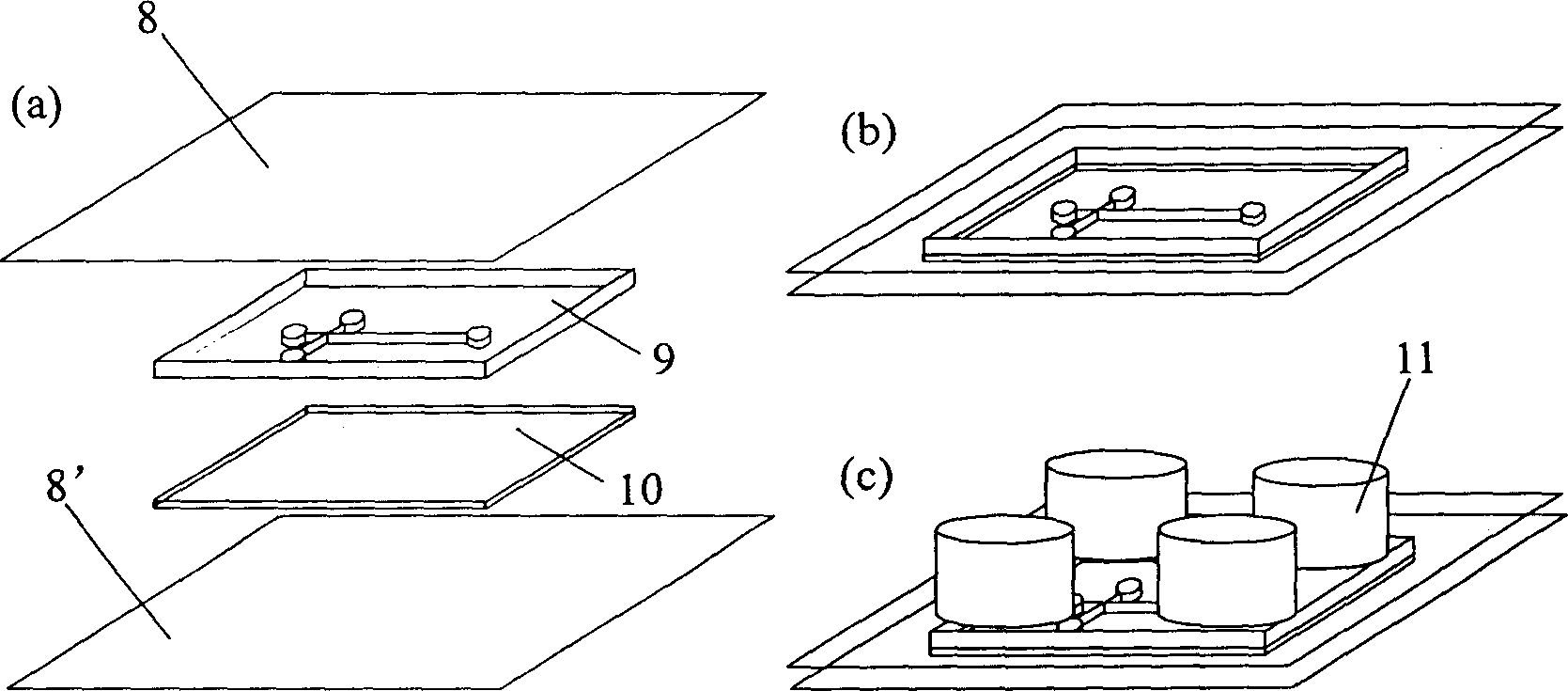

[0022] 1. Cyclopentanone-assisted hot-press packaging of polymethyl methacrylate microfluidic chips

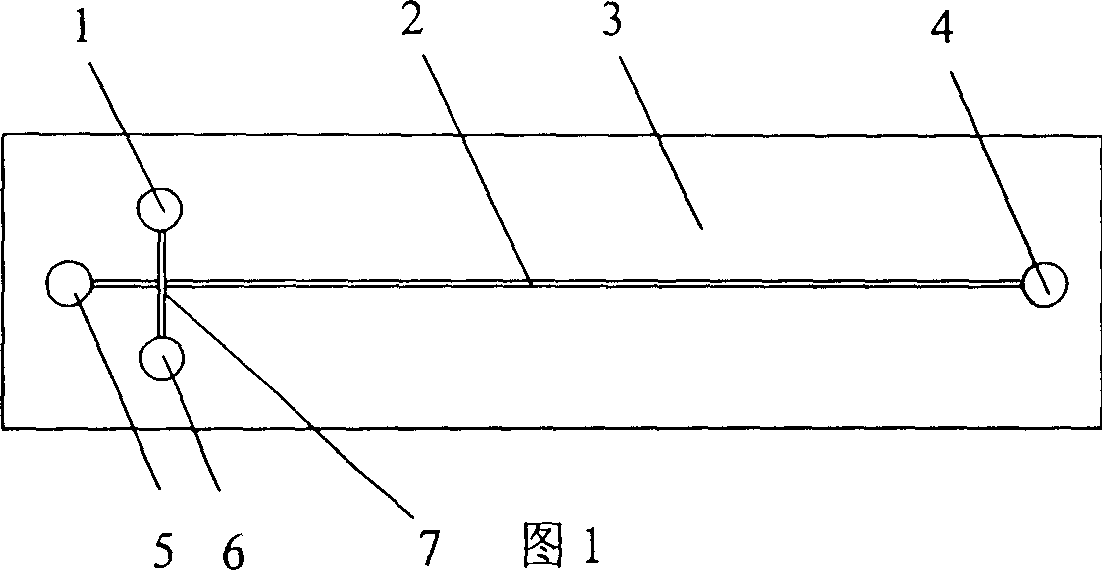

[0023] (A) The design of the microfluidic chip uses Adobe Illustrator 10.0 software to design the microfluidic channels and solution connection holes of the chip, and uses a high-resolution (3600dpi) laser phototypesetting system to print a mask negative on a polyester transparent film. The width of the microfluidic channel is 50 μm, and the solution connection hole is a circular hole with a diameter of 2 mm, in which the microfluidic channel (separation capillary 2 and sampling capillary 7) and solution holes 1, 4, 5 and 6 (Fig. 1) are transparent, and the remaining Part is black. The positive image of the microfluidic chip is shown in Figure 1. The separation microfluidic channel 2 is 5.0 cm long, and the sampling microfluidic channel 7 is 0.5 cm long, and the distance from the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com