Hafnium-containing material for film formation, method for producing the same, and method for producing hafnium-containing thin film using the same

一种制造方法、铪膜的技术,应用在化学仪器和方法、金属材料涂层工艺、半导体/固态器件制造等方向,能够解决再现性差、成膜温度高等问题,达到抑制气化特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

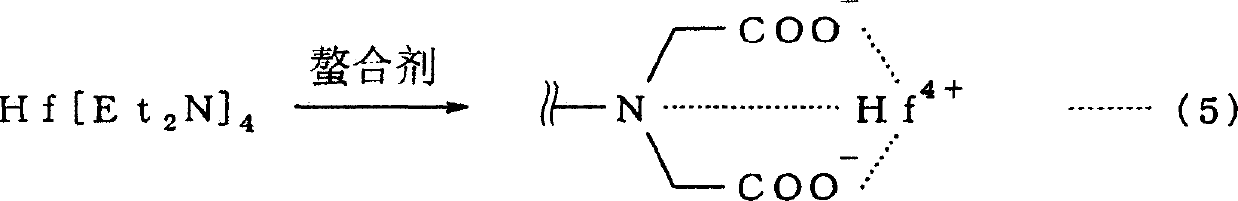

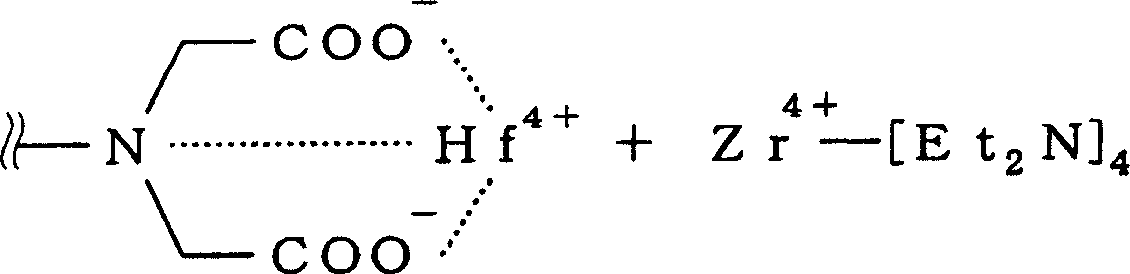

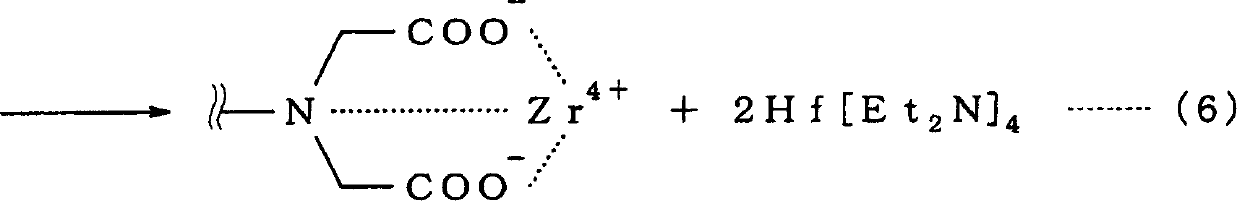

Method used

Image

Examples

Embodiment 1

[0115] First, commercially available hafnium tetrachloride and toluene containing more than 1000 ppm of zirconium element were prepared respectively, and hafnium tetrachloride was suspended in toluene to prepare a suspension. In addition, prepare 3-chloro-hexafluoroacetylacetone and 3-chloro-2,4-pentanedione respectively, mix these compounds at a weight ratio of 1:10, and then dilute the mixture with diethyl ether as a solvent to prepare a diluent , so that 80% of the total ratio is solvent. The suspension and the diluent are mixed to form a reaction solution of hafnium tetrachloride.

[0116] Then, a toluene solvent is added to alkali metals such as lithium metal, sodium metal or potassium metal, and heated to 50° C. to react. The obtained supernatant reaction solution was slowly added dropwise to the hafnium tetrachloride reaction solution under ice cooling. Next, the hafnium tetrachloride reaction liquid to which the supernatant reaction liquid was added dropwise was filt...

Embodiment 2

[0120] Except repeatedly carrying out 15 petroleum ether extractions, prepare Hf (Et 2 N) 4 . The obtained Hf(Et 2 N) 4 The Zr content contained in is measured by UV-VIS absorption spectrometry and is 100 ppm. The Zr content is 100ppm of Hf (Et 2 N) 4 As a hafnium-containing film-forming material.

Embodiment 3

[0122] Except repeatedly carrying out 18 petroleum ether extractions, prepare Hf (E t N) 4 . The obtained Hf(Et 2 N) 4 The Zr content contained in is measured by UV-VIS absorption spectrometry and is 50 ppm. The Zr content is 50ppm of Hf (Et 2 N) 4 As a hafnium-containing film-forming material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com