Method for producing manganese-zinc ferrite particle material and mixed carbonate utilizing waste dry battery

A technology of manganese-zinc ferrite and waste dry batteries, which is applied in the direction of battery recycling, recycling technology, and regeneration of useful parts, and can solve problems such as complex separation process, low recovery rate, and high added value of manganese-zinc ferrite particles , to achieve high economic benefits and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

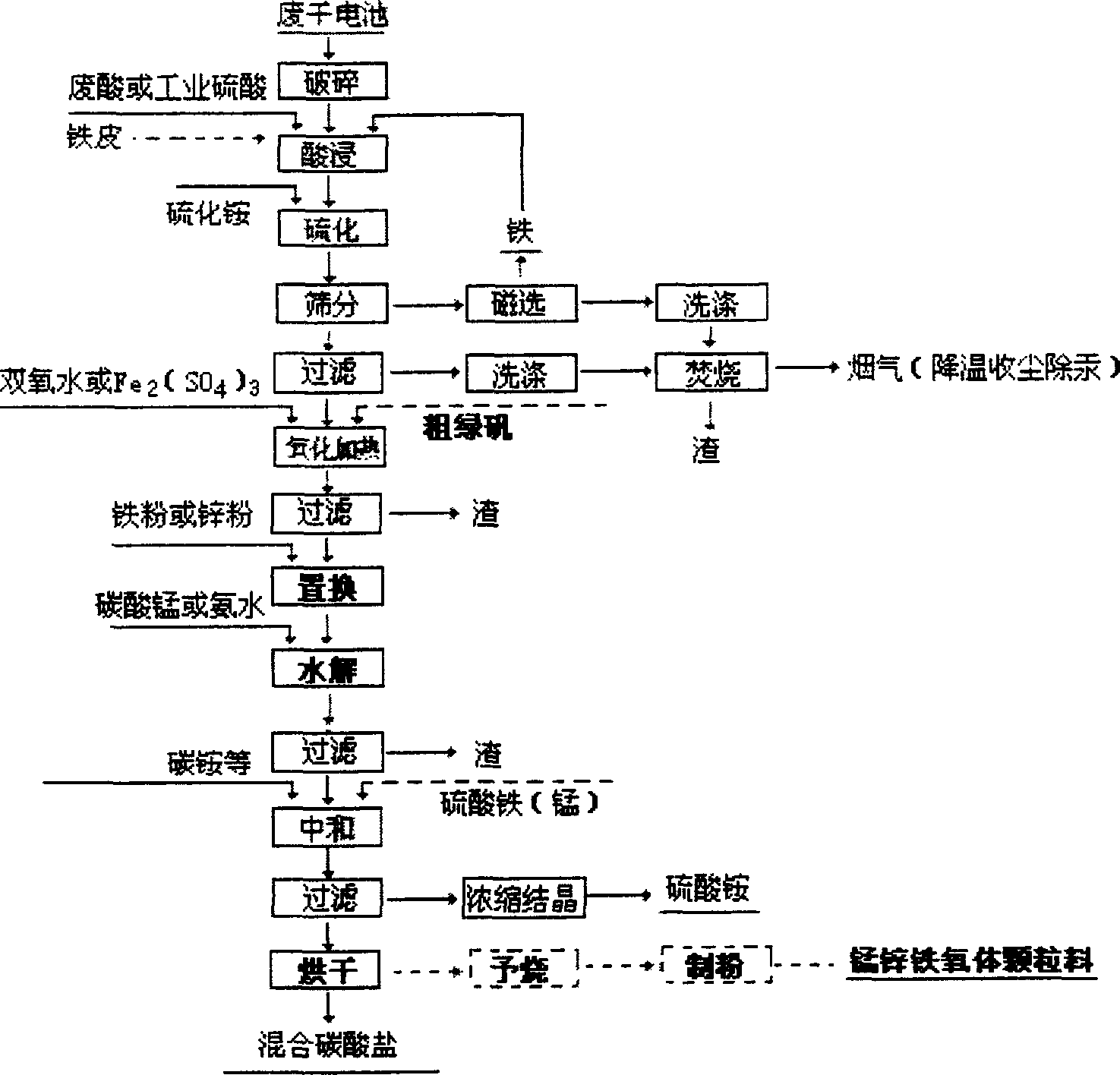

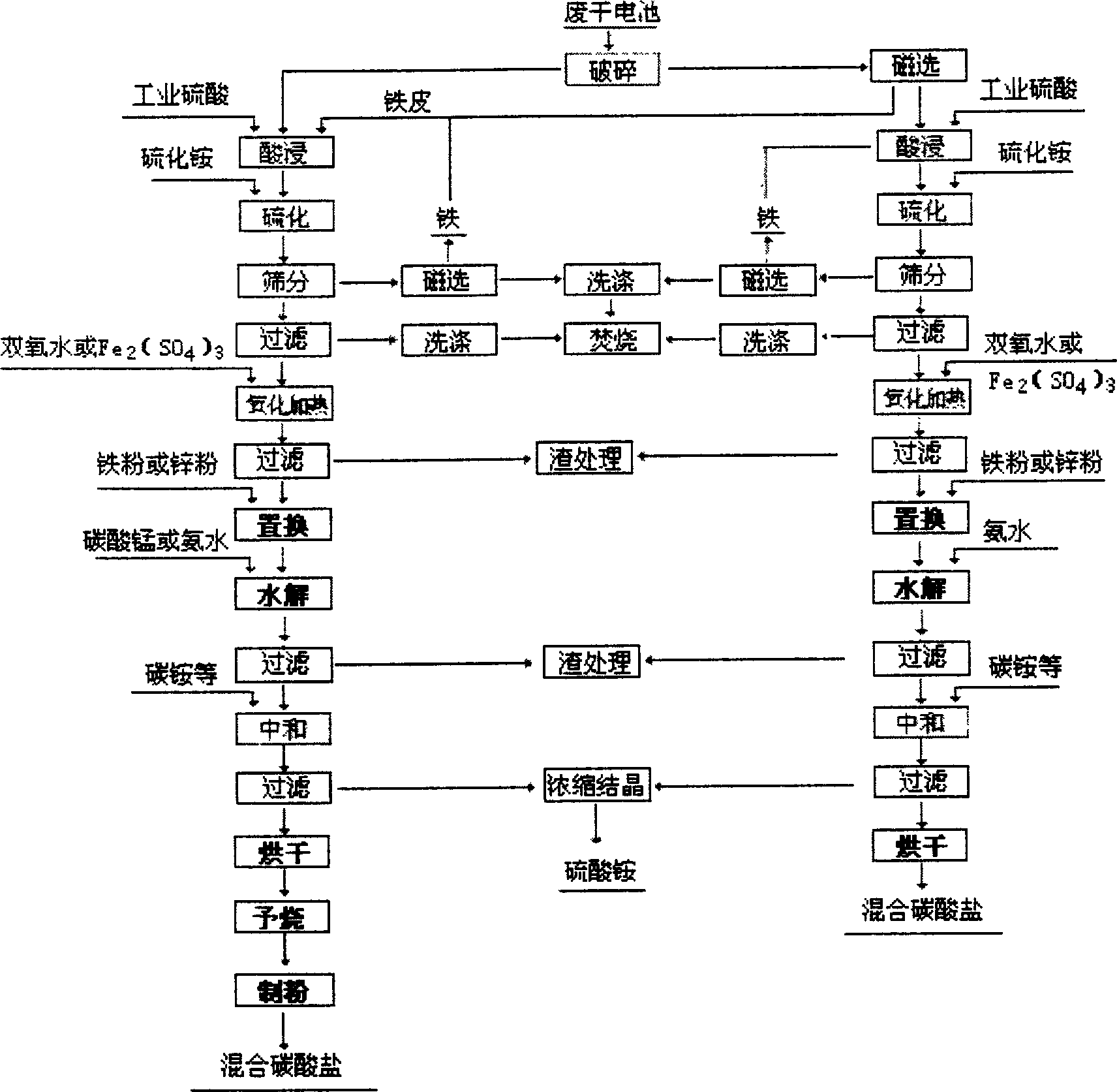

Method used

Image

Examples

Embodiment 1

[0026] Take two parts of 4 kg of broken waste dry batteries, wash them twice with demineralized water, separate and wash the water after sedimentation, add 25 liters of waste sulfuric acid (containing 180g / l of sulfuric acid) from a titanium dioxide factory to one part, and add 25 liters of industrial sulfuric acid to the other part. liters (containing sulfuric acid 180g / l), and then heating and leaching, the leaching temperature is 80-85°C, and the leaching time is 4 hours. After the reaction is completed, the pH value of the solution is about 1, and 60 milliliters of 8% ammonium sulfide solution is added dropwise and stirred for 2 hours, and then the large particles are sieved out and then filtered. The filtrate is about 22 liters, and the mercury content is less than 0.05 mg / liter. Add Fe containing 100 grams of iron in the filtrate 2 (SO 4 ) 3solution, heated to a reaction temperature of 90-95° C., and a reaction time of 3 hours, then filtered after cooling down. Add 30...

Embodiment 2

[0028] Take 4 kg of broken waste dry batteries, wash them twice with demineralized water, separate and wash the water after sedimentation, add 52 liters of industrial sulfuric acid (containing 180 g / l of sulfuric acid), and then add 2.8 kg of iron sheets magnetically separated from waste dry batteries, and then heat and leach , the leaching temperature is 80-85°C, and the leaching time is 4 hours. After the reaction is completed, the pH value of the solution is about 1, and 60 milliliters of 8% ammonium sulfide solution is added dropwise and stirred for 2 hours, and then the large particles are sieved out and then filtered. The filtrate is about 50 liters, and the mercury content is less than 0.05 mg / liter. Add 100 grams of Fe containing iron in the filtrate 2 (SO 4 ) 3 solution, heated to a reaction temperature of 90-95° C., and a reaction time of 3 hours, then filtered after cooling down. Add 30 grams of iron powder to the filtrate for replacement, and then add 15 grams o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com