Chinese medicine preparation and set of apparatuses thereof

A technology for preparation process and complete set of equipment, which is applied in pharmaceutical formulations, medical preparations containing active ingredients, unknown raw materials, etc., can solve the problems of uneven drying, difficult to extract products, insufficient sterilization, etc., and achieves slag removal and It is convenient to clean the tank, reduce the loss of drug efficacy, and retain the effect of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

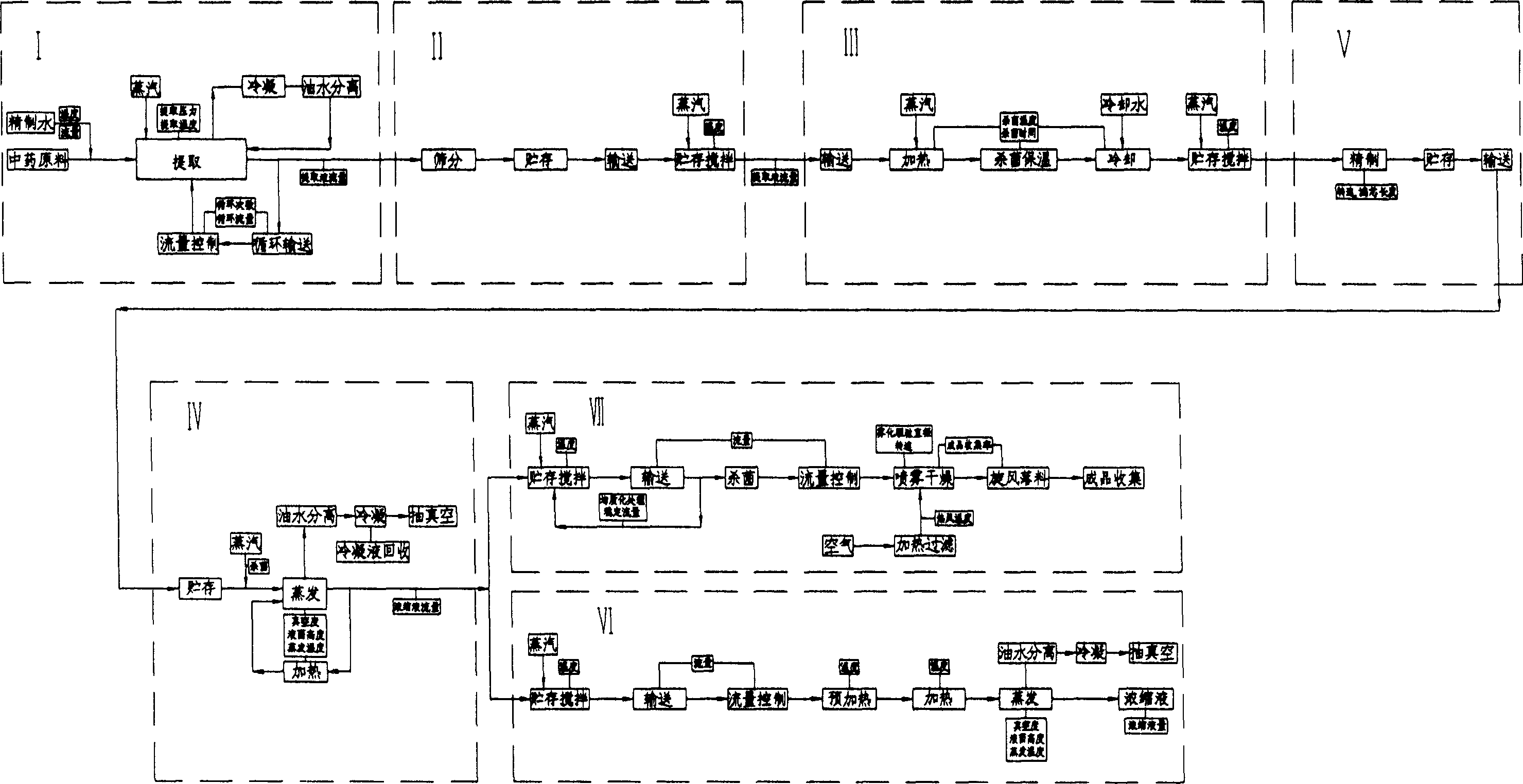

[0015] Such as figure 1 As shown, the process of the present invention includes extraction I, solid-liquid separation II, heat sterilization III, refining V and vacuum concentration IV carried out in sequence. Concentrate VI, if dry finished material is to be produced, spray-dry VI after the vacuum concentration treatment of the liquid medicine.

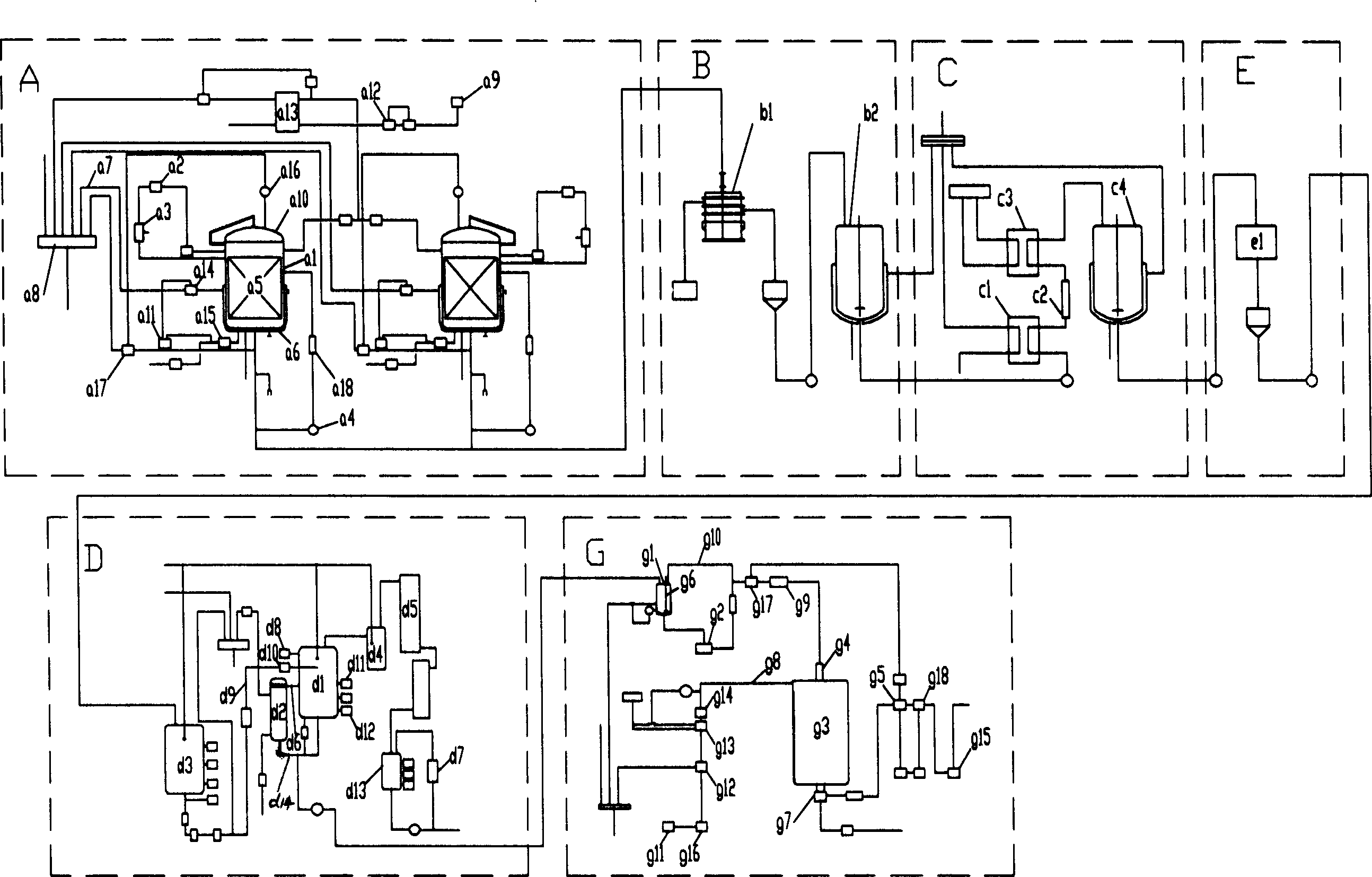

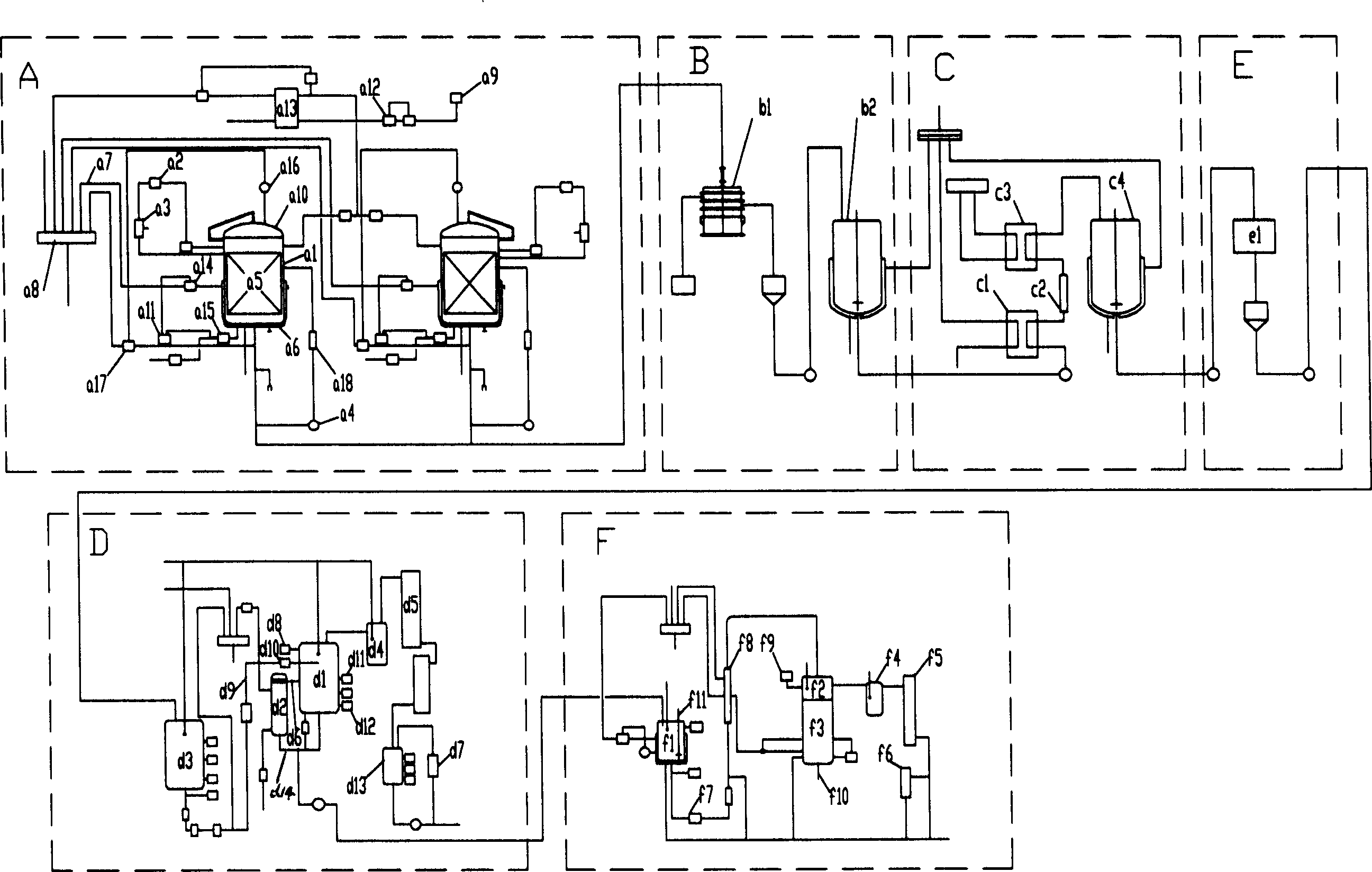

[0016] Such as figure 2 As shown, the equipment for preparing the thick paste finished product of the present invention includes extraction equipment A, solid-liquid separation device B, sterilization device C, refining device E, vacuum concentration device D and secondary concentration device sequentially connected through a liquid supply pipeline. Such as image 3 As shown, the equipment for preparing dry finished materials includes extraction equipment A, solid-liquid separation equipment B, sterilization equipment C, refining equipment E, vacuum concentration equipment D and spray drying equipment G connected in sequence throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com