Preparation of chitin oligose compound

A technology of chitooligosaccharides and compounds, which is applied in the field of preparation of chitooligosaccharides, can solve the problems of reducing the action point of degradation, prolonging the reaction time, and reducing the reaction speed, so as to achieve short degradation reaction time, reduce losses and Effects of waste and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

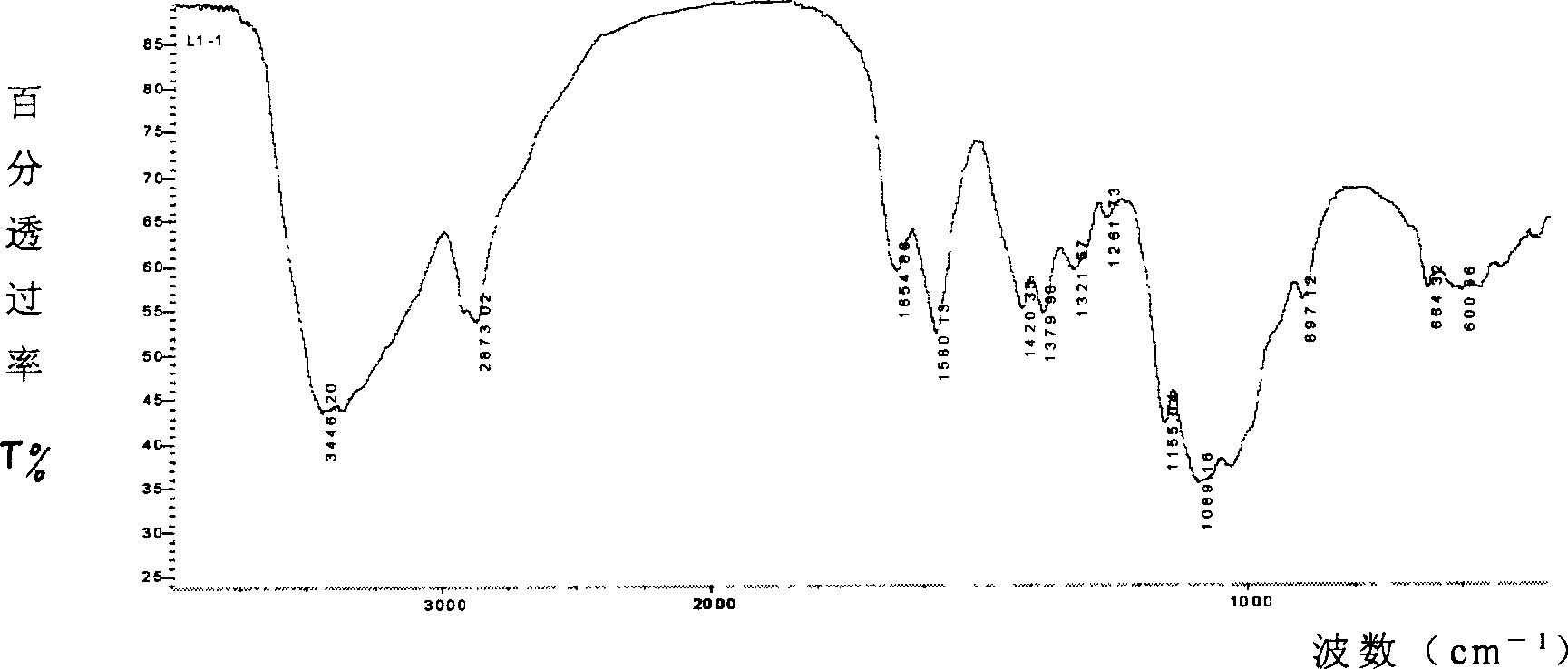

Embodiment 1

[0019] Weigh an appropriate amount of polysaccharide powder of the shell, dissolve it into a viscous solution with 15 times its weight and 4% (V / V) acetic acid, stir evenly, keep the temperature at 50°C, and add a concentration of 30% (V / V ) hydrogen peroxide solution, make R=1, react for 2 hours, then add 10mol / L potassium hydroxide solution, adjust the pH value of the reaction medium to 7, continue to react for 1 hour, cool to room temperature, and use solution volume 3 times Precipitate with ethanol, centrifuge, and dry the obtained precipitate at 40°C to obtain the chitooligosaccharide compound. Grind the dried product to 20 mesh, and measure its molecular weight with an Ubbelohde viscometer to be 8.70×10 3 , and its yield was 62.1%.

Embodiment 2

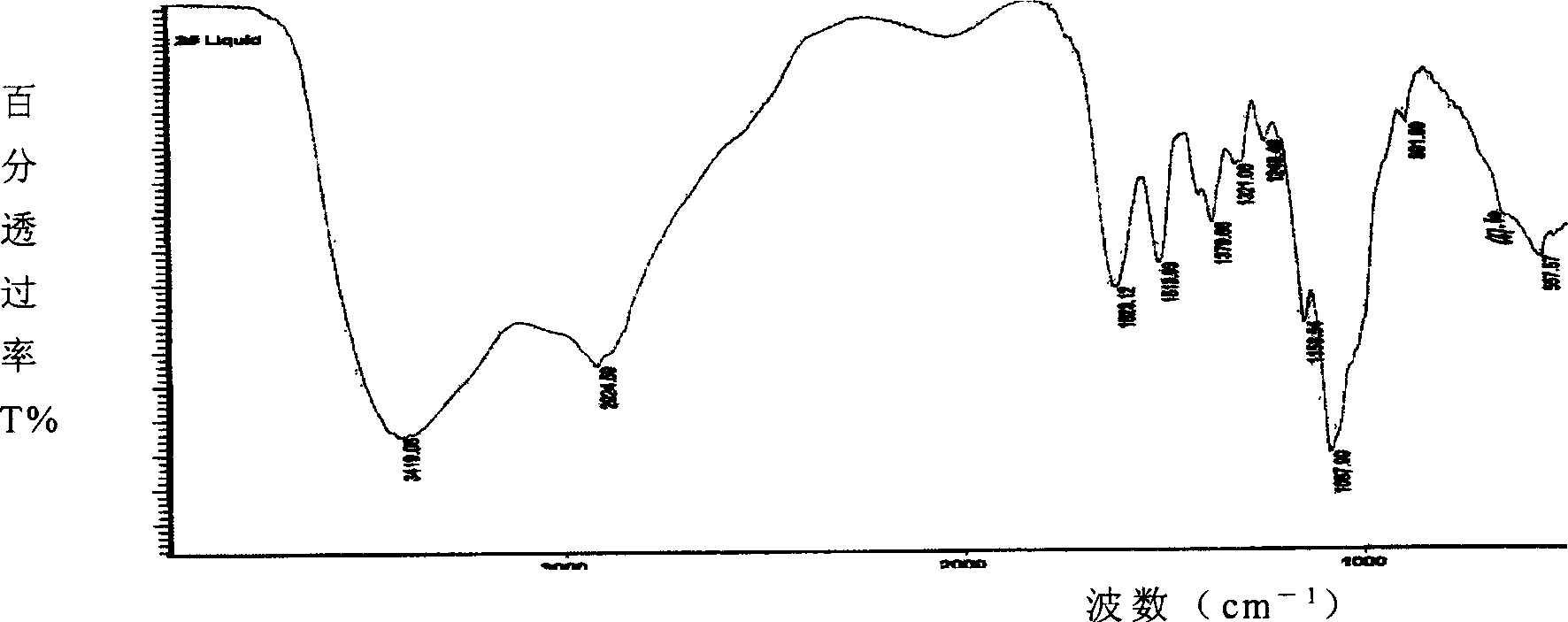

[0021] Take an appropriate amount of chitosan powder, dissolve it into a viscous solution with 20 times its weight and 5% (V / V) acetic acid, stir evenly, and add a concentration of 30% (V / V) at a constant temperature of 60°C. ) hydrogen peroxide solution, make R=1, react for 4 hours, then add 8mol / L sodium hydroxide solution, adjust the pH value of the reaction medium to be 8, continue to react for 2 hours, after the reaction is completed, part of the water is evaporated under reduced pressure , the volume of the solution is concentrated to about 40% of the original volume, cooled to room temperature, precipitated with ethanol 5 times the volume of the remaining solution, centrifuged, and the resulting precipitate is vacuum-dried at room temperature to obtain the chitooligosaccharide compound. Grind the dried product to 60 mesh, and measure its molecular weight with an Ubbelohde viscometer to be 9.74×10 3 , and its yield was 61%.

Embodiment 3

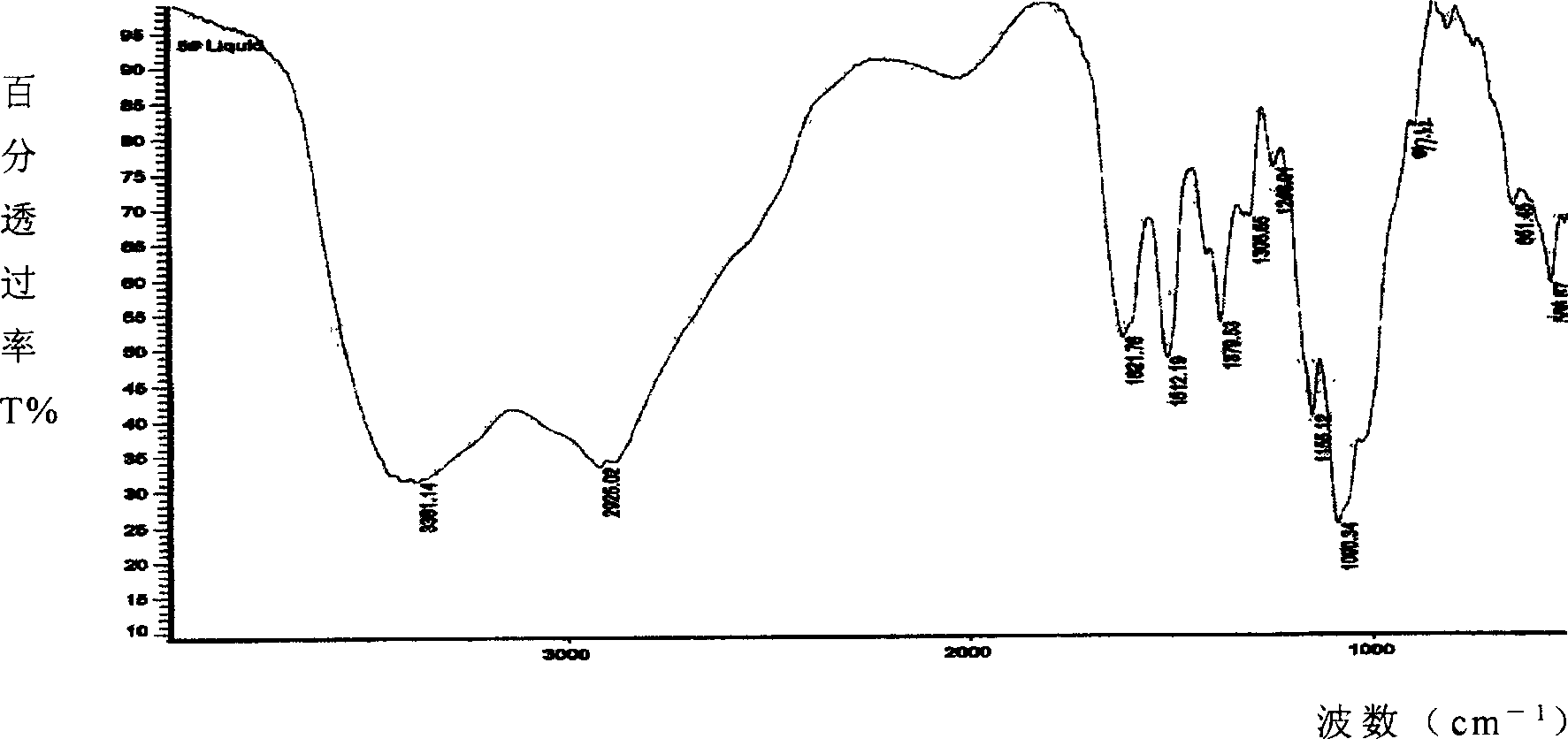

[0023] Take an appropriate amount of chitosan powder, dissolve it into a viscous solution with hydrochloric acid 25 times its weight and a concentration of 3% (V / V), stir evenly, keep the temperature at 80°C, and add a concentration of 30% (V / V) ) hydrogen peroxide solution, make R=1, react for 6 hours, then add 5mol / L sodium hydroxide solution, adjust the pH value of the reaction medium to be 10, continue to react for 3 hours, after the reaction is completed, part of the water is evaporated under reduced pressure , the volume of the solution was concentrated to about 60% of the original volume, cooled to room temperature, precipitated with ethanol 10 times the volume of the remaining solution, centrifuged, and the resulting precipitate was dried at 60°C to obtain the chitooligosaccharide compound. Grind the dried product to 100 mesh, and measure its molecular weight with an Ubbelohde viscometer to be 4.48×10 3 , and its yield was 38.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com