Liquid furtilizer containing humic acid multi nutritive element and mfg. method thereof

A technology of liquid fertilizer and manufacturing method, applied in the directions of organic fertilizers, fertilizer mixtures, fertilization devices, etc., can solve the problems of high cost, low concentration of nutrients, difficult to accept, etc., achieve good drought resistance and stress resistance, rich nutritional value, Improve the effect of fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The manufacture of humic acid multi-nutrient element liquid fertilizer with Huolinhe weathered coal is carried out according to the following procedures;

[0032] (1) Manufacture humic acid serum

[0033] Take Huolinhe weathered coal (humic acid content > 50%), grind the particle size above 60 mesh, weigh 10Kg; KOH 1.2Kg, urea 30Kg, potassium sulfite 0.4Kg, water 100Kg into the stirring tank, the temperature is controlled at 100± 5°C, react for 3 hours. Then through centrifugation or natural precipitation for 20 hours, the supernatant was transferred to the reactor.

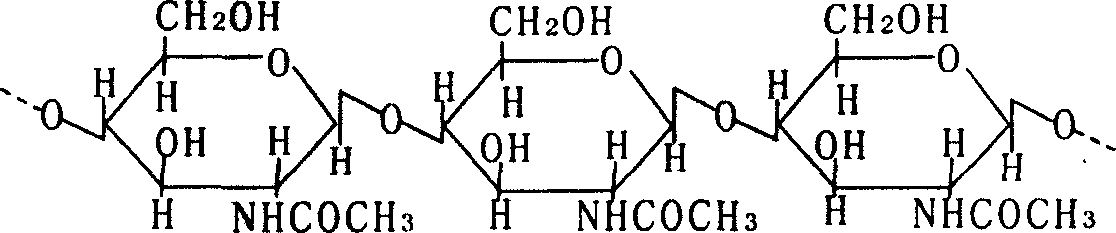

[0034] (2) Manufacture of soluble chitin

[0035] Put 1000 grams of chitin white translucent powder into 20Kg of 40wt% NaOH solution, stir and keep warm at 60°C for 24 hours, the solution is slightly yellow, then add 2wt% CH 3 COOH is made into soluble chitin (ie chitin) solution.

[0036] (3) Manufacture humic acid multi-nutrient liquid fertilizer

[0037] According to the following ratio (weight rat...

Embodiment 2

[0047] Implement the present invention as raw material with lignite, and its technology is as follows:

[0048] (1) Manufacture humic acid serum

[0049] The lignite with humic acid content of about 40% is crushed to more than 100 mesh, weighing 15Kg; NaOH (or Na 2 CO 3 ) 1.0Kg, 45Kg of urea, 0.2Kg of sodium sulfite, and 180Kg of water were put into a stirred tank at 80°C, and reacted for 5 hours. After precipitation, centrifuge to remove solid impurities or insoluble matter, and transfer the clear liquid into the reaction kettle.

[0050] (2) Manufacture of soluble chitin

[0051] Put 500 grams of chitin powder into 20Kg of 40wt% NaOH solution, react at a temperature of 140°C for 1 hour to obtain a yellow-brown liquid and then put it into 2wt% CH 3 COOH solution for later use.

[0052] (3) Manufacture humic acid multi-nutrient liquid fertilizer

[0053] Based on the humic acid clear liquid as 100Kg, add the following raw materials:

Embodiment 3

[0062] The peat containing 30wt% humic acid is used as the raw material. Because the peat has many impurities, it must be crushed and removed before it can be used.

[0063] (1) Manufacture humic acid serum

[0064] After removing impurities, the peat containing about 30% humic acid is crushed to 120 mesh, weighing 25Kg; Na 2 CO 3 2Kg, (NH4 ) SO 3 Add 3Kg of urea and 75Kg of urea into 300Kg of water and put them into the stirring tank together, react at a temperature of 90°C for 4 hours, and after 24 hours of precipitation, the part of the clear liquid is drawn out and transferred into the reactor.

[0065] (2) Manufacture of soluble chitin

[0066] Put 500 grams of chitin powder into 8Kg of 40wt% NaOH solution, react at 100°C for 3 hours to obtain light yellow liquid, then add 22Kg of 2wt% acetic acid solution to it for later use.

[0067] (3) Manufacture humic acid multi-nutrient liquid fertilizer

[0068] Based on the humic acid clear liquid as 100Kg, add the follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com