Method for structuring field effect transistor in multiple channels from Nano carbon tubes

A technology of field-effect transistors and carbon nanotubes, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting transistor performance, large source-drain electrode size, and inability to form ohmic contacts, etc., to achieve good structural stability performance, the effect of good switching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

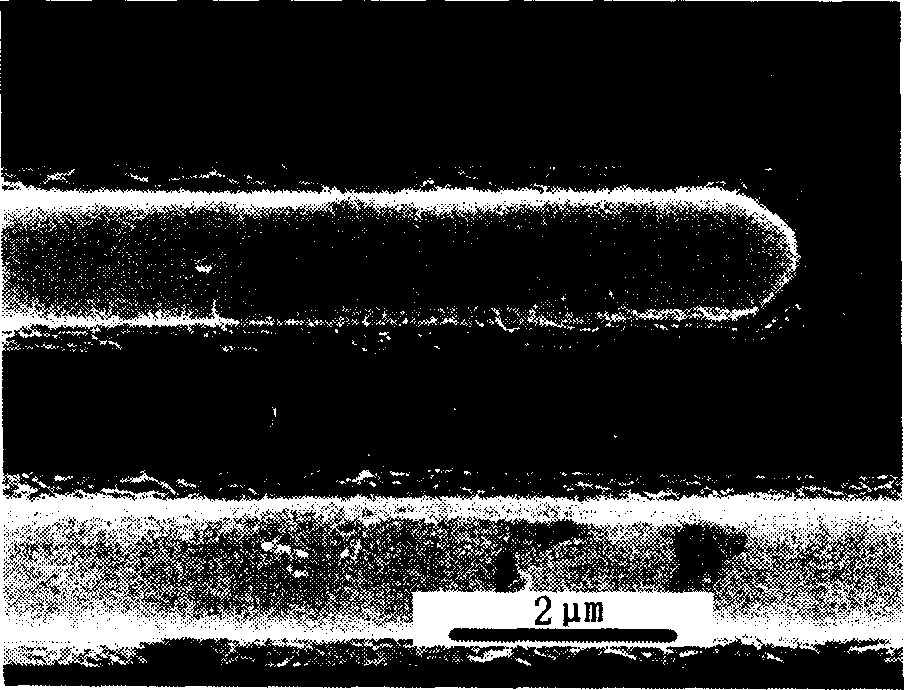

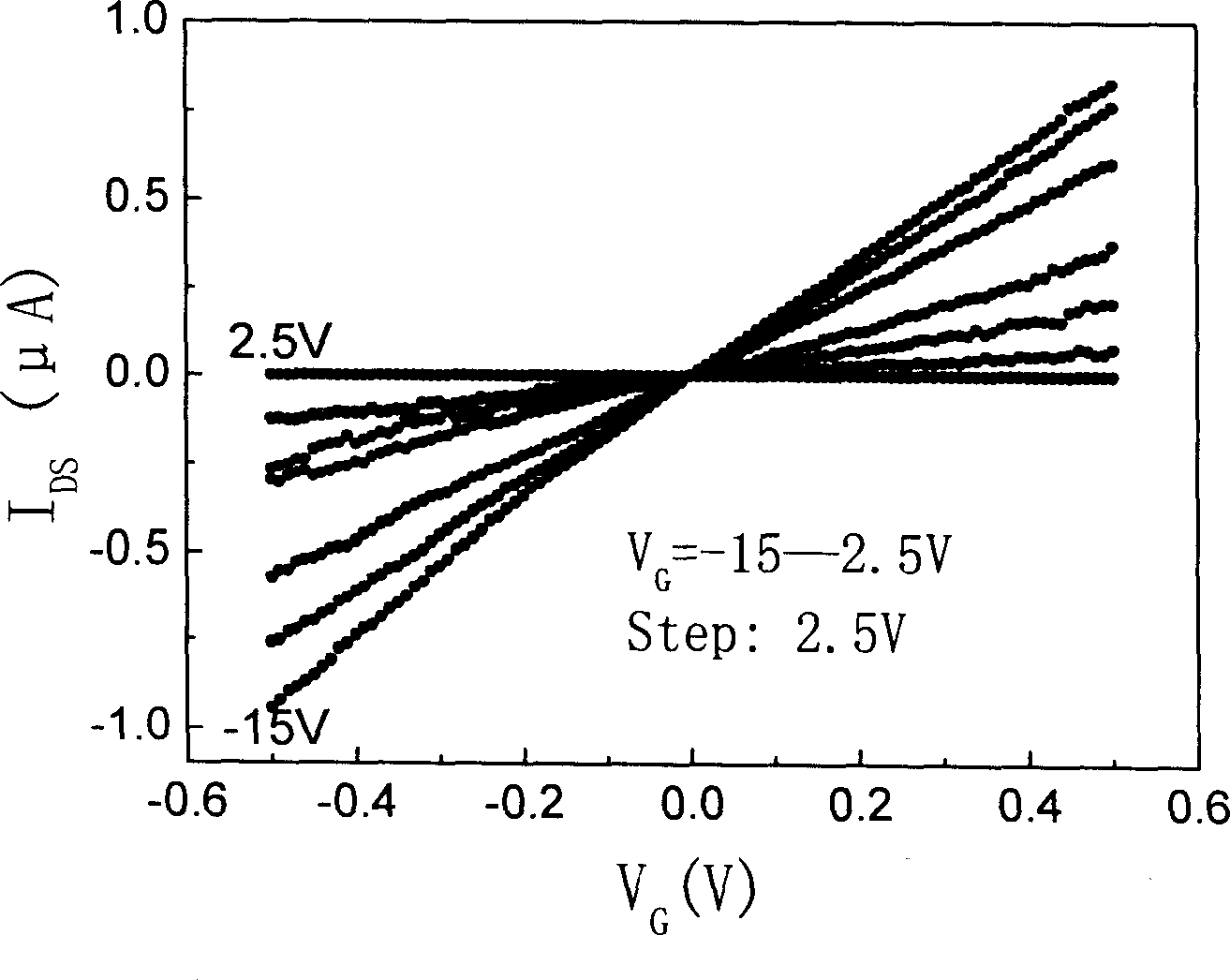

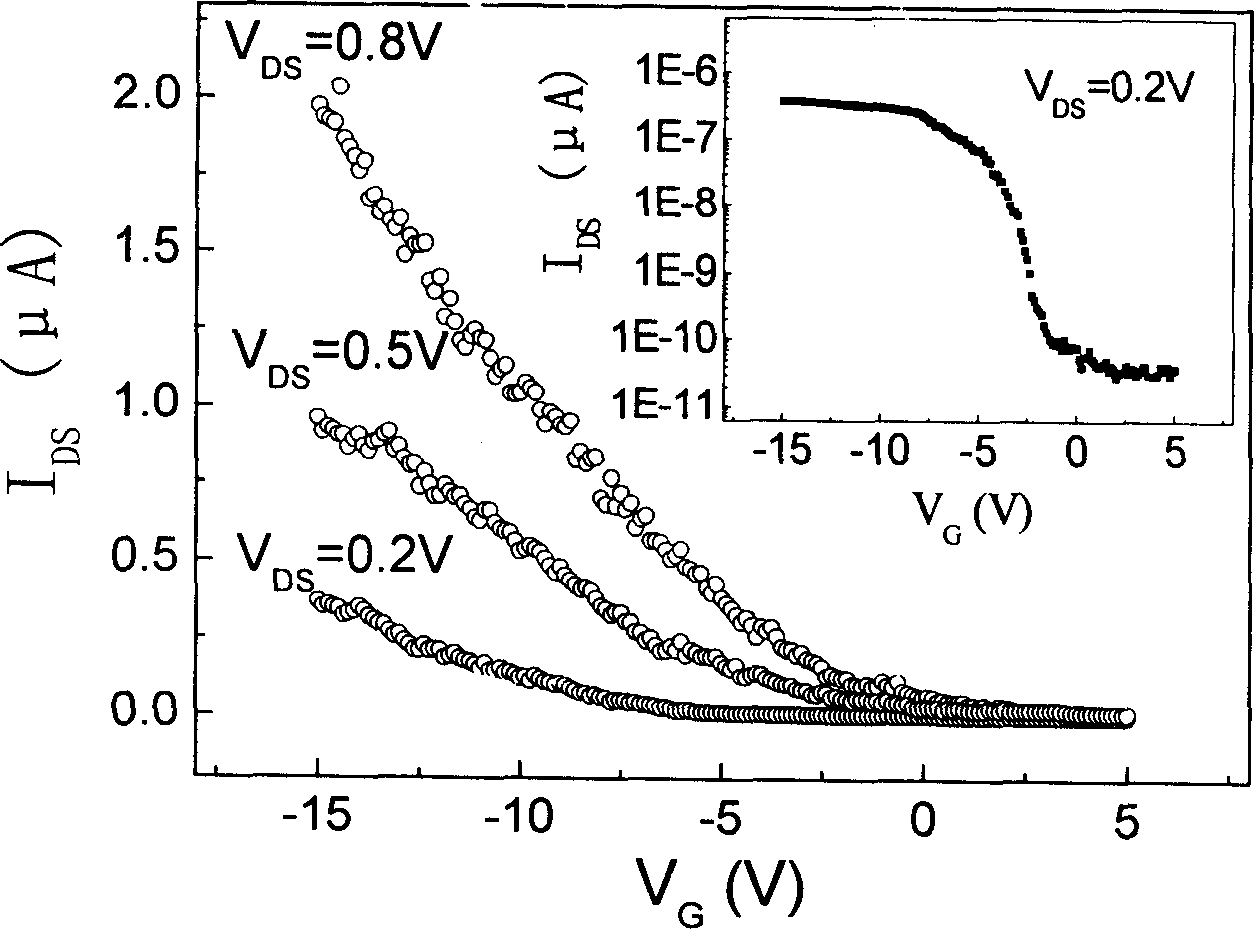

[0031] In this embodiment, a multi-channel field-effect transistor is prepared by directional arrangement of carbon nanotubes chemically modified by surface functional molecules in an alternating electric field. Firstly, the carbon nanotubes are subjected to surface activation treatment, and the carbon nanotubes are refluxed at 100° C. for 30 minutes in a mixed acid prepared by a ratio of 3:1 of concentrated sulfuric acid (concentration: 98%) and concentrated nitric acid (concentration: 68%). Active carboxyl groups are generated on the surface of carbon nanotubes to facilitate the grafting of octadecylamine or DNA molecules on the surface of carbon nanotubes. The surface-activated carbon nanotubes were reacted with octadecylamine and N,N'-dicyclohexylcarbodiimide (DCC) in a ratio of 1:100:30 (mass ratio), at 60°C React for 24 hours to graft octadecylamine on the surface of carbon nanotubes; use a filter membrane with a pore size of 2 μm for suction filtration when cleaning, an...

Embodiment 2

[0035] In this embodiment, a multi-channel field-effect transistor is prepared by directional arrangement of carbon nanotubes chemically modified by surface functional molecules in an alternating electric field. Firstly, the carbon nanotubes are subjected to surface activation treatment, and the carbon nanotubes are refluxed at 140° C. for 30 minutes in a mixed acid prepared by a ratio of 3:1 of concentrated sulfuric acid (concentration: 98%) and concentrated nitric acid (concentration: 68%). Active carboxyl groups are generated on the surface of carbon nanotubes to facilitate the grafting of octadecylamine or DNA molecules on the surface of carbon nanotubes. The carbon nanotubes after the surface activation treatment were reacted with octadecylamine and N, N'-dicyclohexylcarbodiimide (DCC) in a ratio of 1:100:30 (mass ratio), at 110°C The carbon nanotubes were reacted for 24 hours to graft octadecylamine on the surface of the carbon nanotubes; the filter membrane with a pore ...

Embodiment 3

[0038] In this embodiment, a multi-channel field-effect transistor is prepared by directional arrangement of carbon nanotubes chemically modified by surface functional molecules in an alternating electric field. Firstly, the carbon nanotubes are subjected to surface activation treatment, and the carbon nanotubes are refluxed at 120° C. for 30 minutes in a mixed acid prepared by a ratio of 3:1 of concentrated sulfuric acid (concentration: 98%) and concentrated nitric acid (concentration: 68%). Active carboxyl groups are generated on the surface of carbon nanotubes to facilitate the grafting of octadecylamine or DNA molecules on the surface of carbon nanotubes. The carbon nanotubes after the surface activation treatment were reacted with octadecylamine and N,N'-dicyclohexylcarbodiimide (DCC) in a ratio of 1:100:30 (mass ratio), at 90°C The carbon nanotubes were reacted for 24 hours to graft octadecylamine on the surface of the carbon nanotubes; the filter membrane with a pore si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com