Radiation-curing composition, method for storing same, method for forming cured film, method for forming pattern, method for using pattern, electronic component, and optical waveguide

A curable composition and radiation technology, applied in the direction of photosensitive materials, optics, and optomechanical equipment used in optomechanical equipment, to achieve the effect of excellent pattern accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

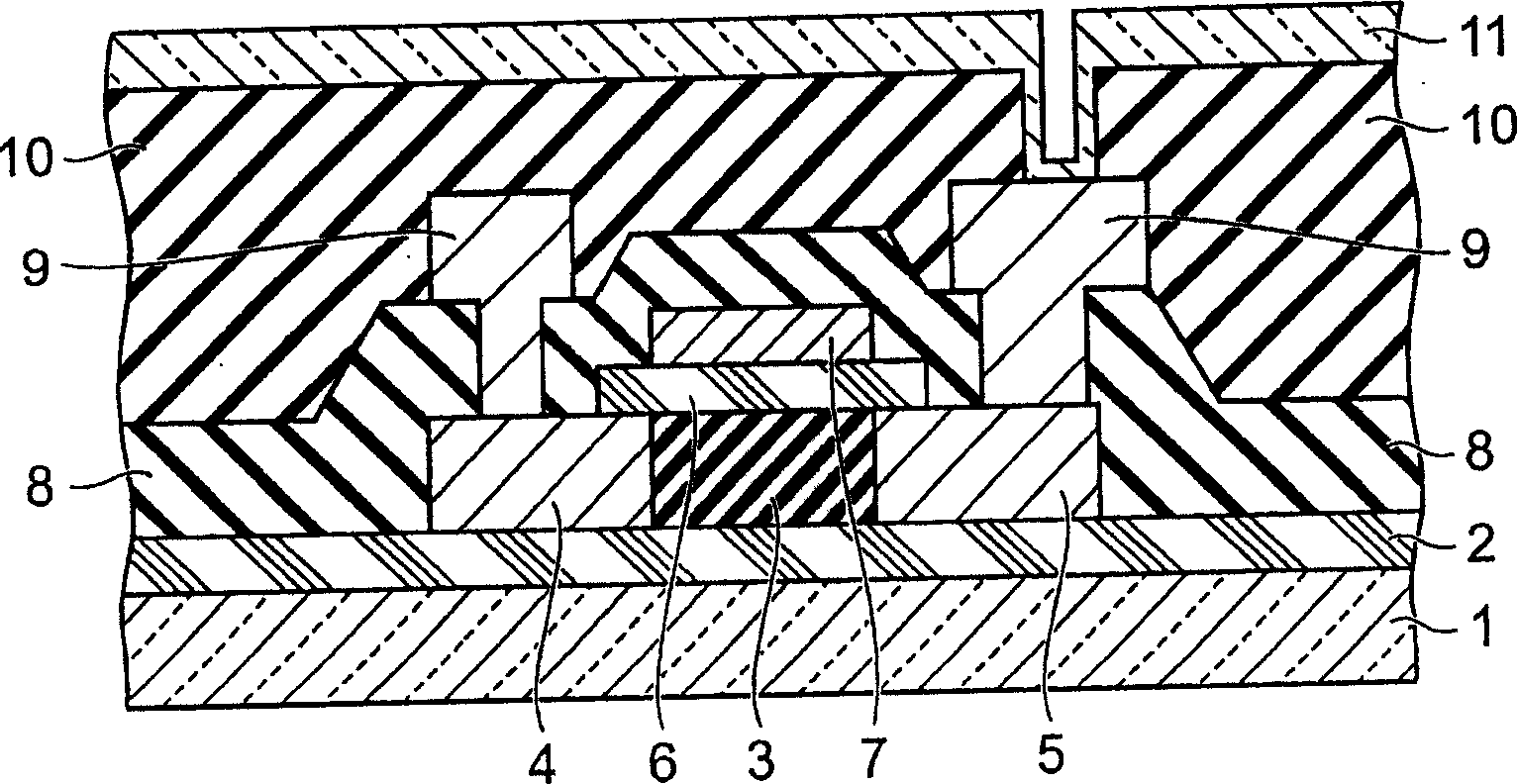

Image

Examples

Embodiment 1

[0163] To a solution in which 317.9 g of tetraethoxysilane and 247.9 g of methyltriethoxysilane were dissolved in 1116.7 g of diglyme, 167.5 g of nitric acid adjusted to 0.644% by weight was added dropwise over 30 minutes while stirring. After completion of the dropwise addition, the reaction was carried out for 3 hours, and a part of ethanol and diglyme were distilled off in a warm bath under reduced pressure to obtain 1077.0 g of a polysiloxane solution. To 525.1 g of this polysiloxane solution, 53.0 g of diglyme, 2.38% by weight of tetramethylammonium nitrate aqueous solution (pH 3.6) and 3.0 g of water were added. Stirring and dissolution were performed for 30 minutes to obtain a polysiloxane solution for a radiation curable composition. The weight average molecular weight of polysiloxane measured by GPC method was 830. 0.193 g of a photoacid generator (PAI-1001, manufactured by Midori Chemical Co., Ltd.) was mixed with 10.0 g of this polysiloxane solution for a radiation...

Embodiment 2

[0166] In the solution that dissolves 96.13g of tetraethoxysilane and 165.44g of methyltriethoxysilane in 562.99g of propylene glycol methyl ether acetate, 75.47g of nitric acid adjusted to 0.644% by weight and 18.9 g of 2.38 weight% tetramethylammonium nitrate aqueous solution (pH 3.6) was prepared. After completion of the dropwise addition, the reaction was carried out for 3 hours, and a part of ethanol and propylene glycol methyl ether acetate generated were distilled off in a warm bath under reduced pressure to obtain 359.94 g of a polysiloxane solution. Propylene glycol methyl ether acetate was added thereto to obtain 450.02 g of a polysiloxane solution for a radiation curable composition. The weight average molecular weight of the polysiloxane measured by the GPC method was 1110. 0.080 g of a photoacid generator (PAI-101, manufactured by Midori Chemical Co., Ltd.) was mixed with 20.0 g of this polysiloxane solution for a radiation curable composition to prepare a radiat...

Embodiment 3

[0169] 0.040 g of a photobase generator (NBC-101, manufactured by Midori Chemical Co., Ltd.) was mixed with 10.0 g of the polysiloxane solution for a radiation-curable composition obtained in Example 2 to prepare a radiation-curable composition. In addition, the usage-amount of (a) component is 20 weight% with respect to the radiation curable composition whole quantity. (b) The usage-amount of a component is 0.4 weight% with respect to the radiation curable composition whole quantity. (d) The usage-amount of a component is 0.1 weight% with respect to the radiation curable composition whole quantity.

[0170] 2 mL of the radiation-curable composition was dropped at the center of a 6-inch silicon wafer, and a coating film was formed on the wafer by spin coating (700 r / min for 30 seconds), and dried for 30 seconds with a 100° C. hot plate. Thereafter, the dried coating film was passed through a mask for a linear pattern negative film with a minimum line width of 2 μm, and was ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com