Microwave depolymerization equipment for medical refuse treatment

A technology for medical waste and treatment equipment, applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve problems such as harm to human health, emission of toxic gases, secondary environmental pollution, etc., to avoid secondary pollution, avoid fuel cost, the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

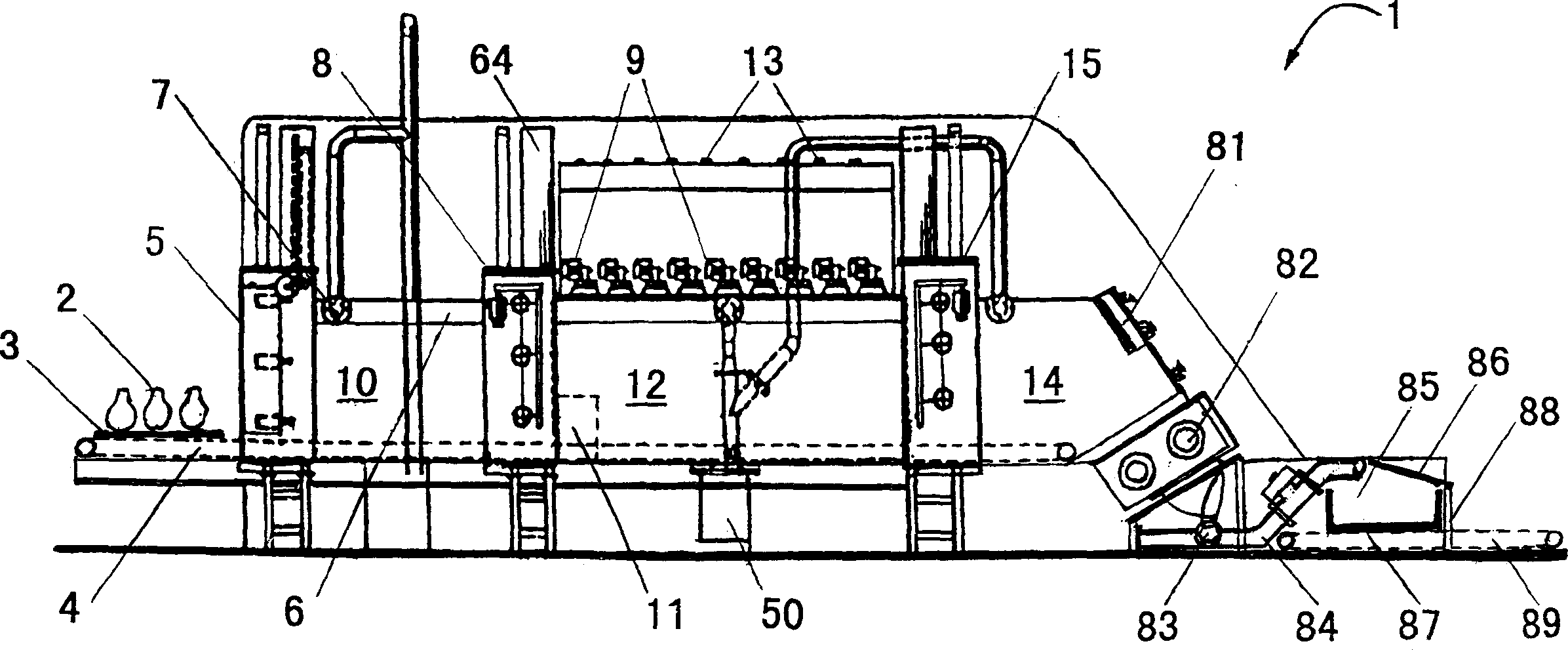

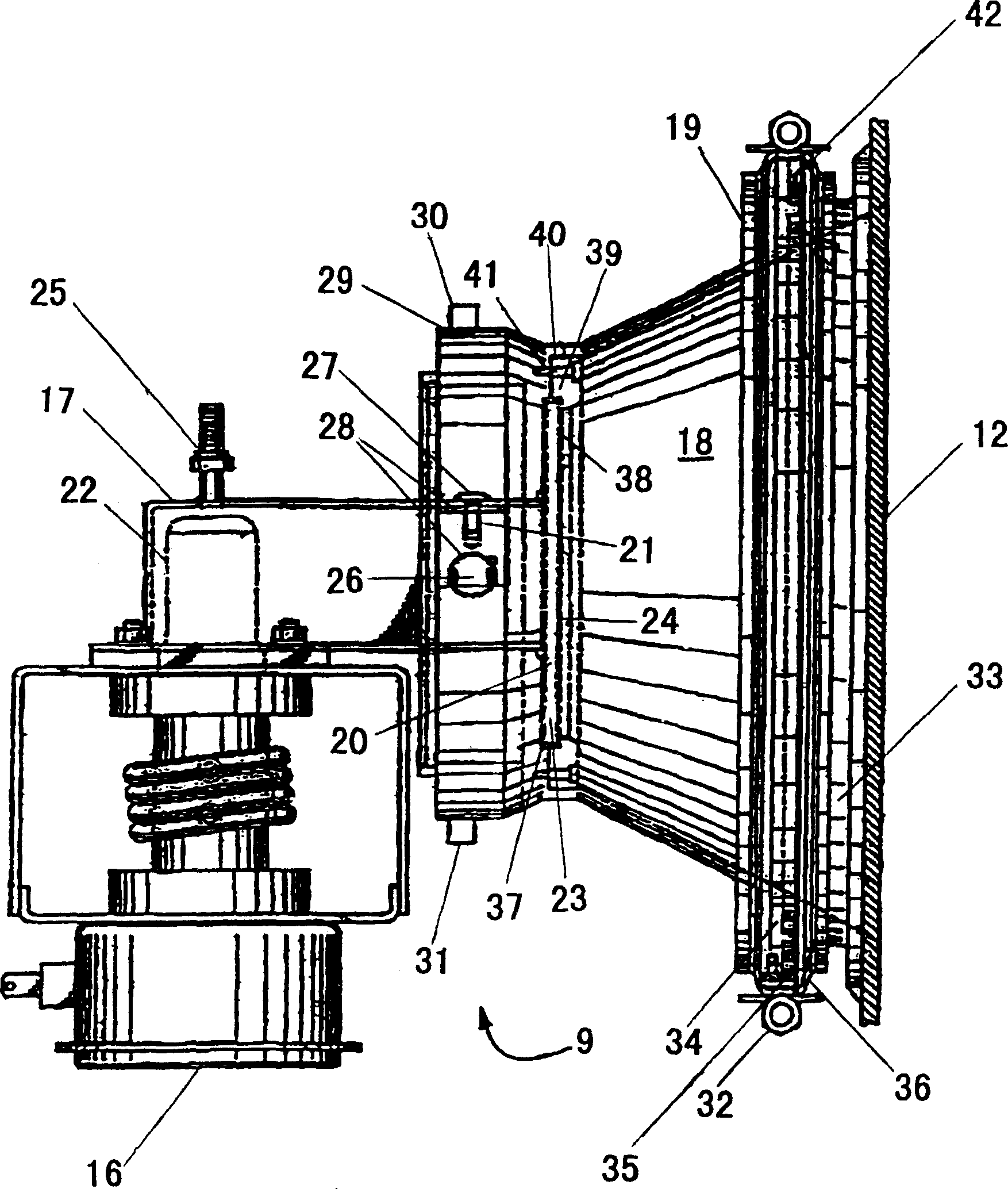

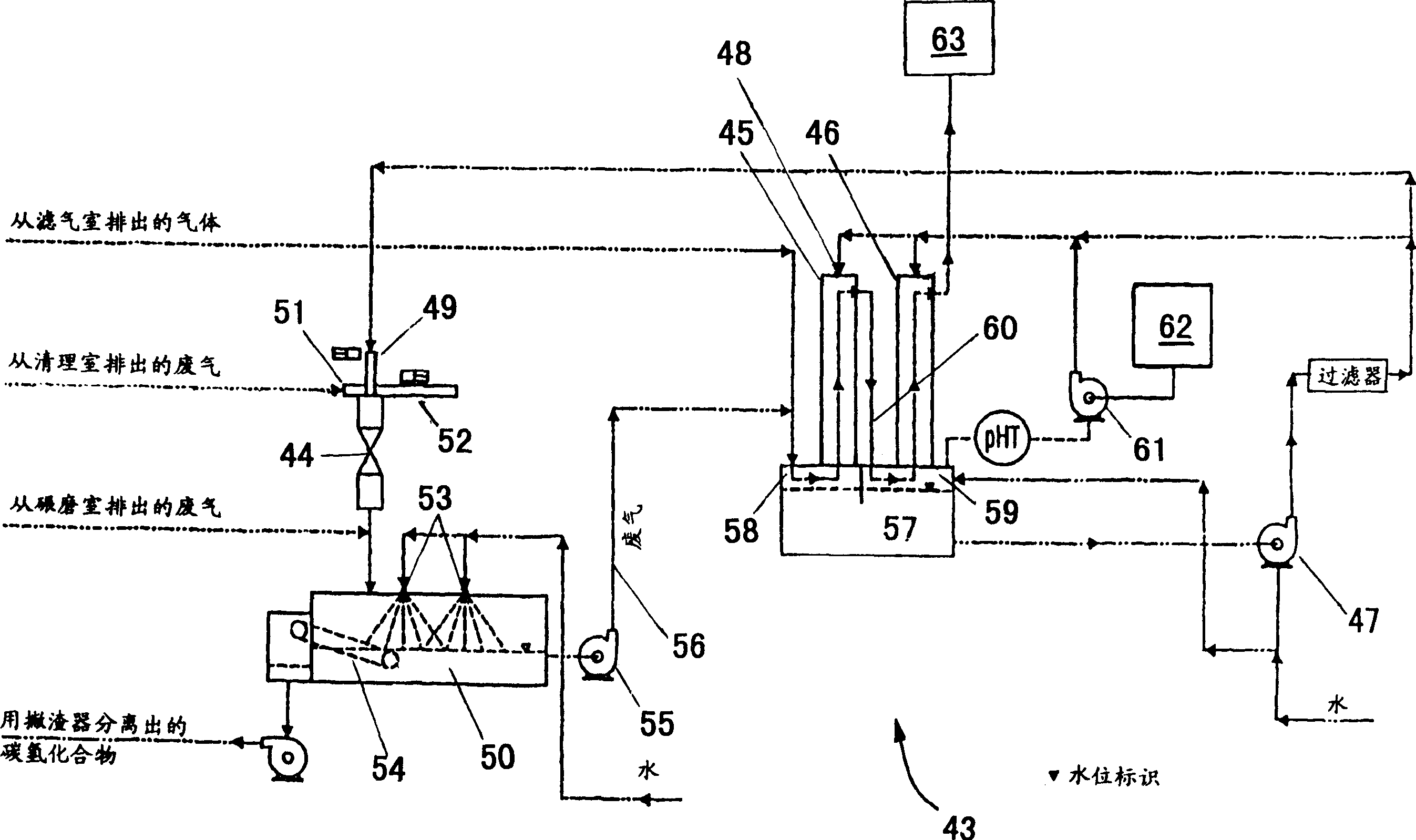

[0027] The entire waste treatment process includes four steps of air filtration, depolymerization, grinding and recycling, which are carried out in four chambers of the medical waste treatment equipment 1 respectively. The air filter chamber 10 is responsible for removing oxygen in the equipment, the cleaning chamber 12 is responsible for using microwaves to depolymerize, disinfect and clean medical waste, the grinding chamber 14 is responsible for cooling, grinding and final treatment of the waste, and the recovery chamber 85 is responsible for centralized treatment The final rubbish is shredded and transported out of the medical waste disposal equipment 1.

[0028] The medical waste 2 is collected in bags or boxes and placed on a cardboard tray 3 , and transported into the medical waste treatment system 1 by a conveyor 4 . Cardboard trays 3 are primarily used to carry waste that may leak out of bags or boxes. The surface of the conveyor 4 is velvet to seal the gap between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com