Process for extracting tea polyphenol, caffeine as a byproduct thereof and tea polysaccharide from tea

A technology of caffeine and tea polyphenols, which is applied in the field of extracting tea polyphenols by-products of caffeine and tea polysaccharides, can solve the problems of toxic solvent residues, etc., and achieve the effects of improving extraction rate, significant effect, and increasing diffusion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

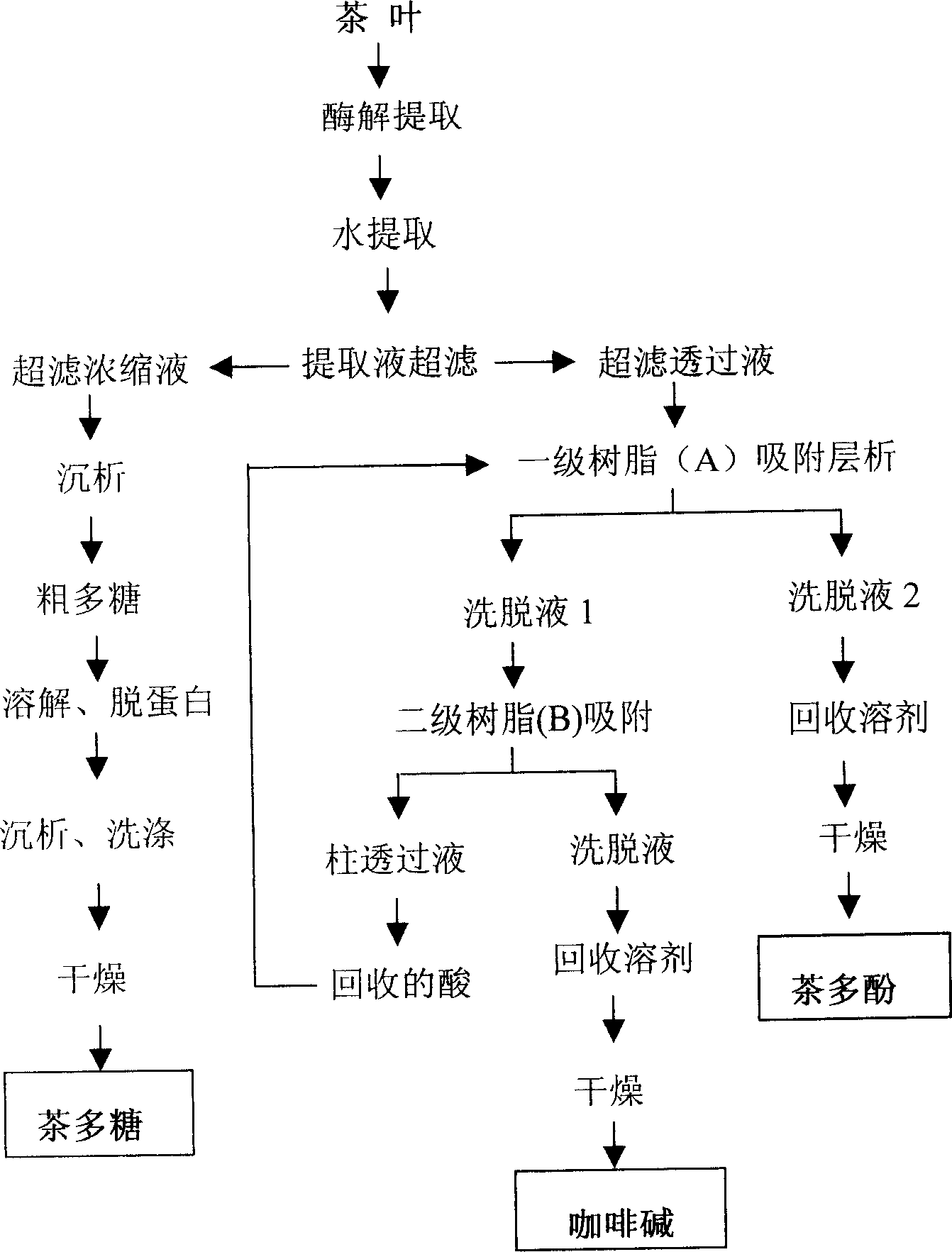

Image

Examples

Embodiment 1

[0051] 1) Add 1kg of tea leaves, add 20L of water, heat up to 40°C, adjust the pH range to 4.5, add 0.8g of compound enzyme solution, and extract for 60 minutes; add 15L of water to the filtered filter residue, temperature 60°C, pH value of 6, and extract for 40 minutes .

[0052] 2) Combine the extracts twice, filter with a polysulfone hollow fiber ultrafiltration membrane with a molecular weight cut-off of 30kD, and precipitate the membrane concentrate to obtain crude tea polysaccharides. Trichloroacetic acid precipitates protein, and the filtrate after filtering protein is subjected to alcohol precipitation, filtration, washing and drying to obtain tea polysaccharide. The sugar content of tea polysaccharide is 50.5%, and the yield accounts for 2.5% of the dry weight of tea leaves.

[0053] 3) The XAD7 resin column on the membrane permeate absorbs tea polyphenols and caffeine. In the resin column after adsorption, the first stage uses 8BV (BV value is the resin bed volume)...

Embodiment 2

[0056] 1) Add 30L of water to 1kg of tea leaves, raise the temperature to 50°C, adjust the pH value to 5.5, add 2.0g of compound enzyme solution, and extract for 70 minutes. Add 10 L of water to the filtered filter residue at a temperature of 50° C. and a pH value of 6, and extract for 30 minutes.

[0057] 2) Combine the extracts twice, filter with a polysulfone hollow fiber ultrafiltration membrane with a molecular weight cut-off of 50kD, the membrane concentrate is precipitated by ethanol to obtain crude tea polysaccharides, and after dissolving the crude polysaccharides in water, add 1 / 10 volume of 5% trichloride Acetic acid precipitation and deproteinization, and the filtered filtrate is subjected to alcohol precipitation, filtration, washing and drying to obtain tea polysaccharide. The sugar content of tea polysaccharide is 53.2%, and the yield accounts for 2.4% of the dry weight of tea leaves.

[0058] 3) HP on membrane permeate 2 The MG resin column adsorbs tea polyph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com