L-leucine high-yield bacterium and fermentation method using the same for L-leucine production

A technology of Leucine and Corynebacterium glutamicum, applied in the field of bioengineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

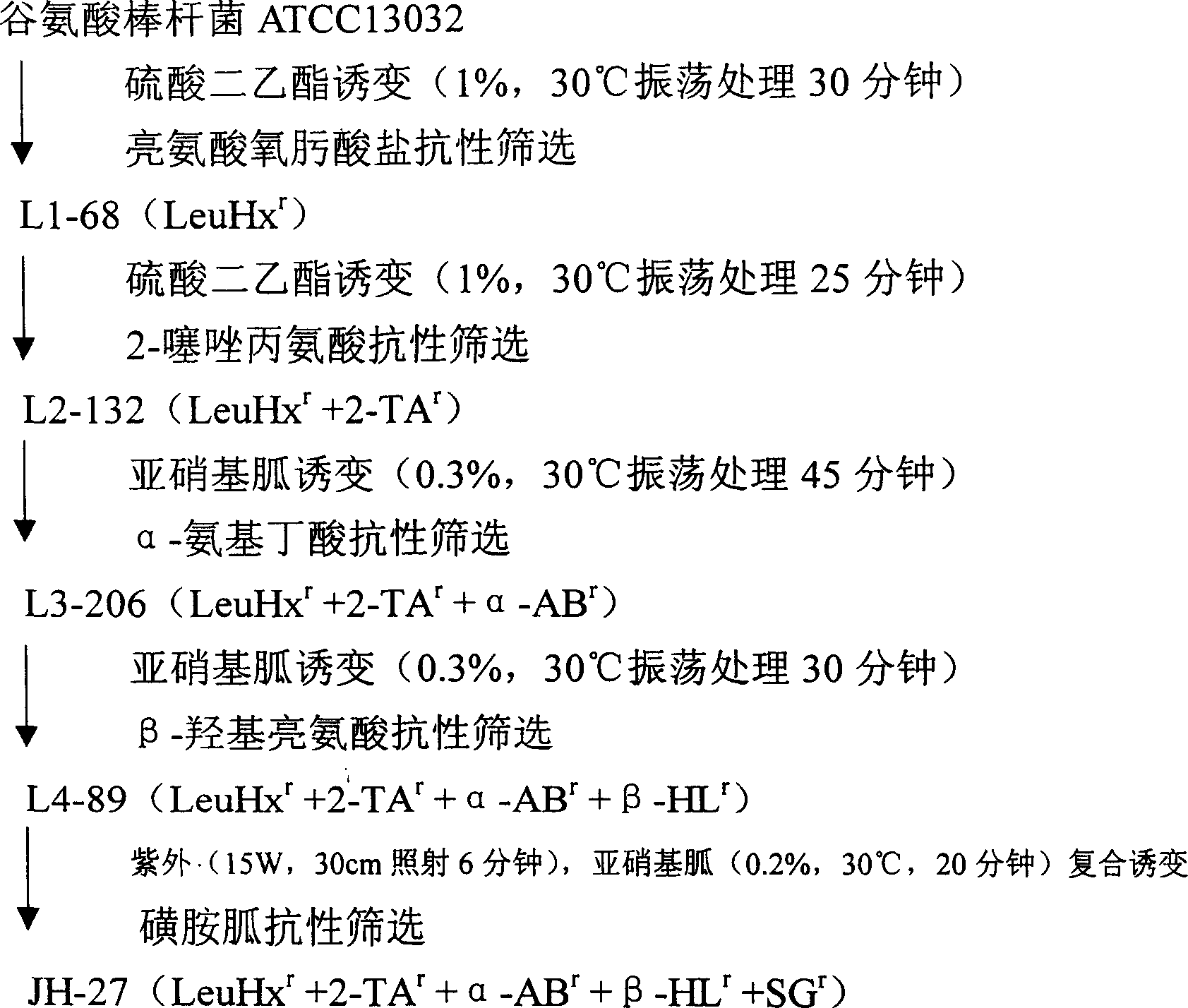

[0019] Example 1 Preparation of mutant strains resistant to leucine hydroxamate.

[0020] The starting strain Corynebacterium glutamicum (Corynebacterium glutamicum) ATCC 13032 was subjected to routine mutagenesis treatment with diethyl sulfate (1%, 30°C, 30 minutes), and then coated with 5-10g / L leucine oxygen On the basic medium of hydroxamate, culture at 30°C for 2 to 4 days, pick the colony grown on this medium as a mutant strain resistant to leucine hydroxamate, and then carry out L-leucine Acid fermentation test, among these mutants, the mutant with the highest L-leucine production is called Corynebacterium glutamicum L1-68, and its L-leucine production is 8.9 g / L.

Embodiment 2

[0021] Example 2 Preparation of mutants resistant to 2-thiazolealanine.

[0022] Corynebacterium glutamicum (Corynebacterium glutamicum) L1-68 obtained in Example 1 was subjected to routine mutagenesis treatment with diethyl sulfate (1%, 30° C., 25 minutes), and then coated in a solution containing 5-10 g / L On the basic medium of 2-thiazolealanine, culture at 30°C for 2 to 4 days, pick the colonies grown on this medium as mutants resistant to 2-thiazolealanine, and then carry out L- Leucine fermentation test, among these mutants, the mutant with the highest L-leucine production is called Corynebacterium glutamicum L2-132, and its L-leucine production is 13 g / L.

Embodiment 3

[0023] Example 3 Preparation of mutant strains resistant to α-aminobutyric acid.

[0024] The Corynebacterium glutamicum (Corynebacterium glutamicum) L2-132 obtained in Example 2 was subjected to routine mutagenesis treatment with nitrosoguanidine (0.3%, 30° C., 45 minutes), and then coated in a solution containing 20-40 g / L On the basic medium of α-aminobutyric acid, culture at 30°C for 2 to 4 days, pick the colonies grown on this medium as mutants resistant to α-aminobutyric acid, and then carry out L-leucine Acid fermentation test, among these mutant strains, the mutant strain with the highest L-leucine production is called Corynebacterium glutamicum L3-206, and its L-leucine production is 18 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com