Method for melting and forming micro lens array utilizing halftone mask photo etching

A technology of half-tone mask and microlens array, applied in the field of forming microlens array, to achieve the effects of expanding the processing depth range, simplifying the process, and expanding the processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

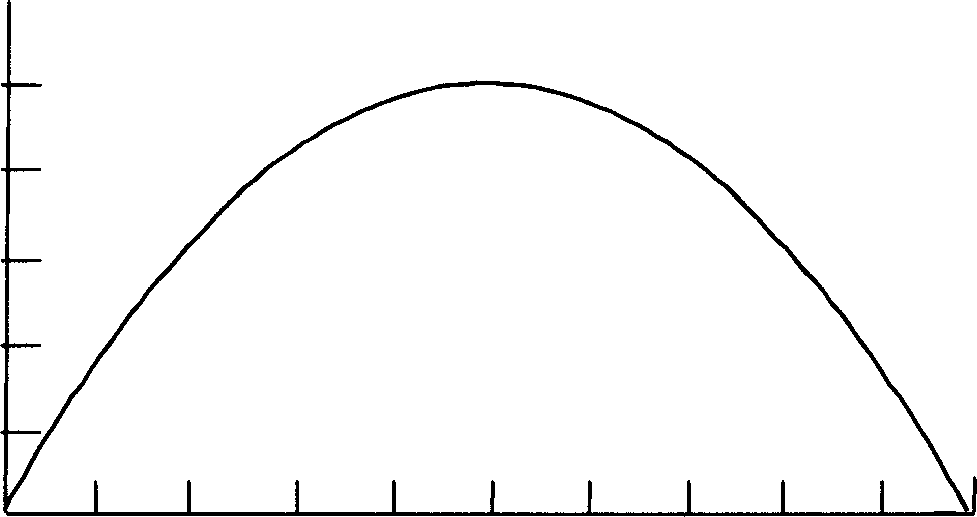

[0022] Embodiment 1 is a continuous deep-relief microlens array with an aperture of =1500 μm and an etching depth of h=5 μm manufactured by the method of the present invention. Positive photoresist is used as photoresist material. Its production process is as follows:

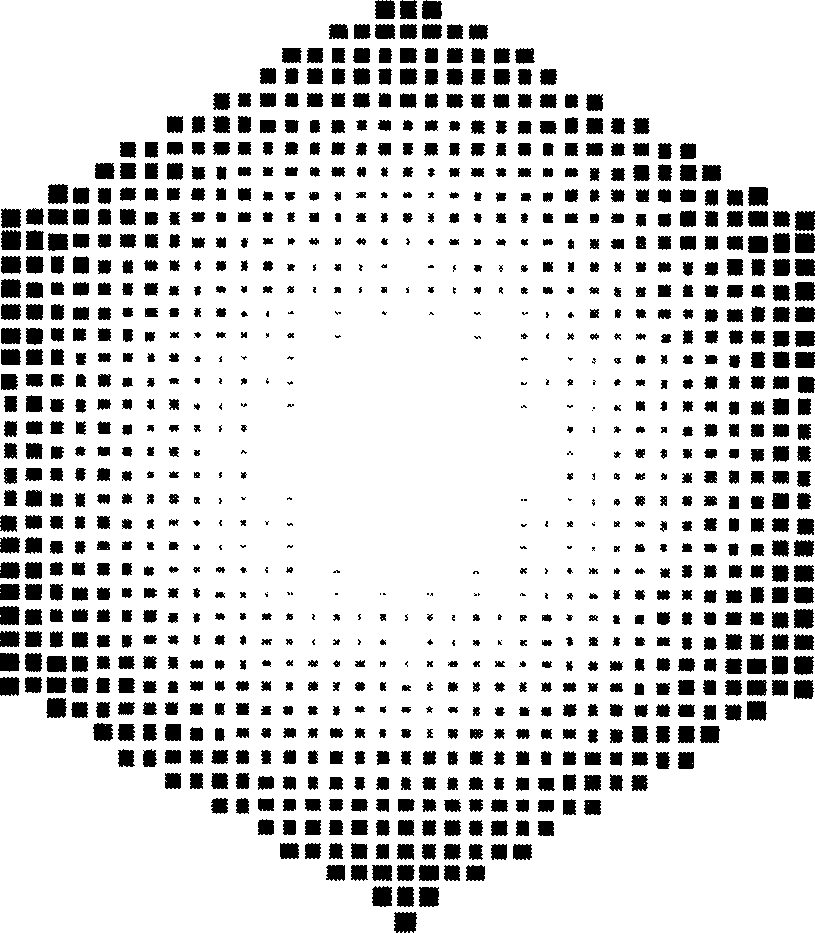

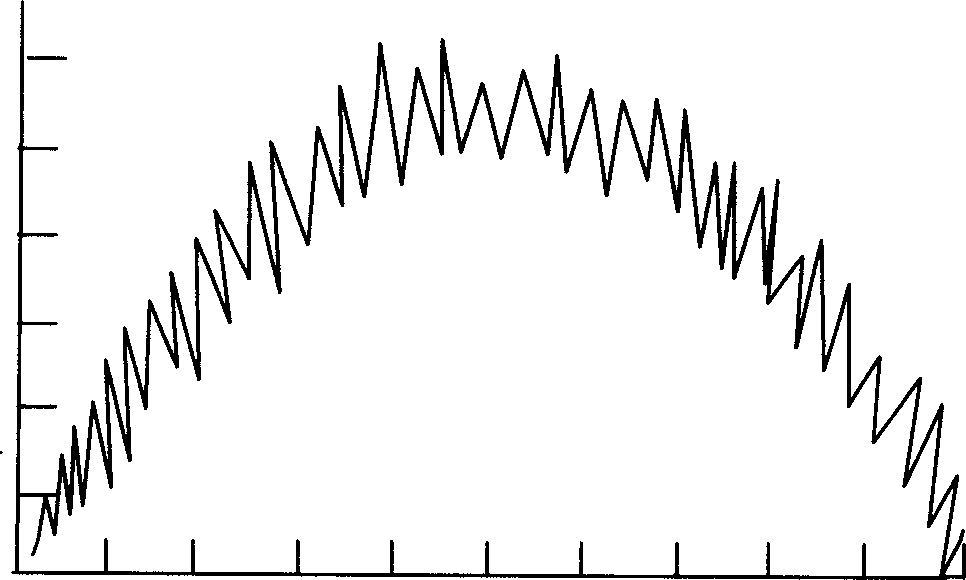

[0023] (1) First, design and manufacture a halftone photolithography mask according to the structural parameters and surface shape of the target microlens array, such as figure 1 shown. According to the radius of curvature of the target microlens and the relationship between the expected surface finish of the target microlens and the quantization accuracy of the halftone mask. It is calculated that in order to obtain a microstructure with a surface finish of less than 20 microns, the quantization accuracy of the mask needs to be 10.3 microns, and 10 microns is used in the experiment. And use this size as the quantization unit, convert the undulation of the target micro-relief into the density function of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com