Sweet potato and its production technology

A technology of sweet potato protein and production technology, which is applied in plant protein processing, food preparation, food science, etc., and can solve problems hindering the development and application of sweet potato protein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment takes red winter sweet potato as an example to describe the preparation method of sweet potato protein extract in detail.

[0020] a. Cut the washed sweet potatoes into 2cm square pieces, and put them into 0.5g / Kg sodium bisulfite ice solution to prevent browning of the potato pieces.

[0021] b. Beat the potato cubes into a slurry with a grinder, and filter.

[0022] c. Centrifuge the filtrate at room temperature for 30 minutes at 3000 g (centrifuge model: LXY-IIB, Shanghai Anting Scientific Instrument Factory), so that the starch in the filtrate is fully precipitated.

[0023] d. Adjust the pH of the supernatant to 4 with 2N hydrochloric acid (analytical grade).

[0024] e. Centrifuge at room temperature for 30 minutes at 3000 g (the centrifuge model is the same as above).

[0025] f. Pour off the supernatant, dilute the precipitate with 10 times of 5% sodium chloride solution, and adjust to neutrality with 2N sodium hydroxide.

[0026] g. Freeze-dr...

Embodiment 2

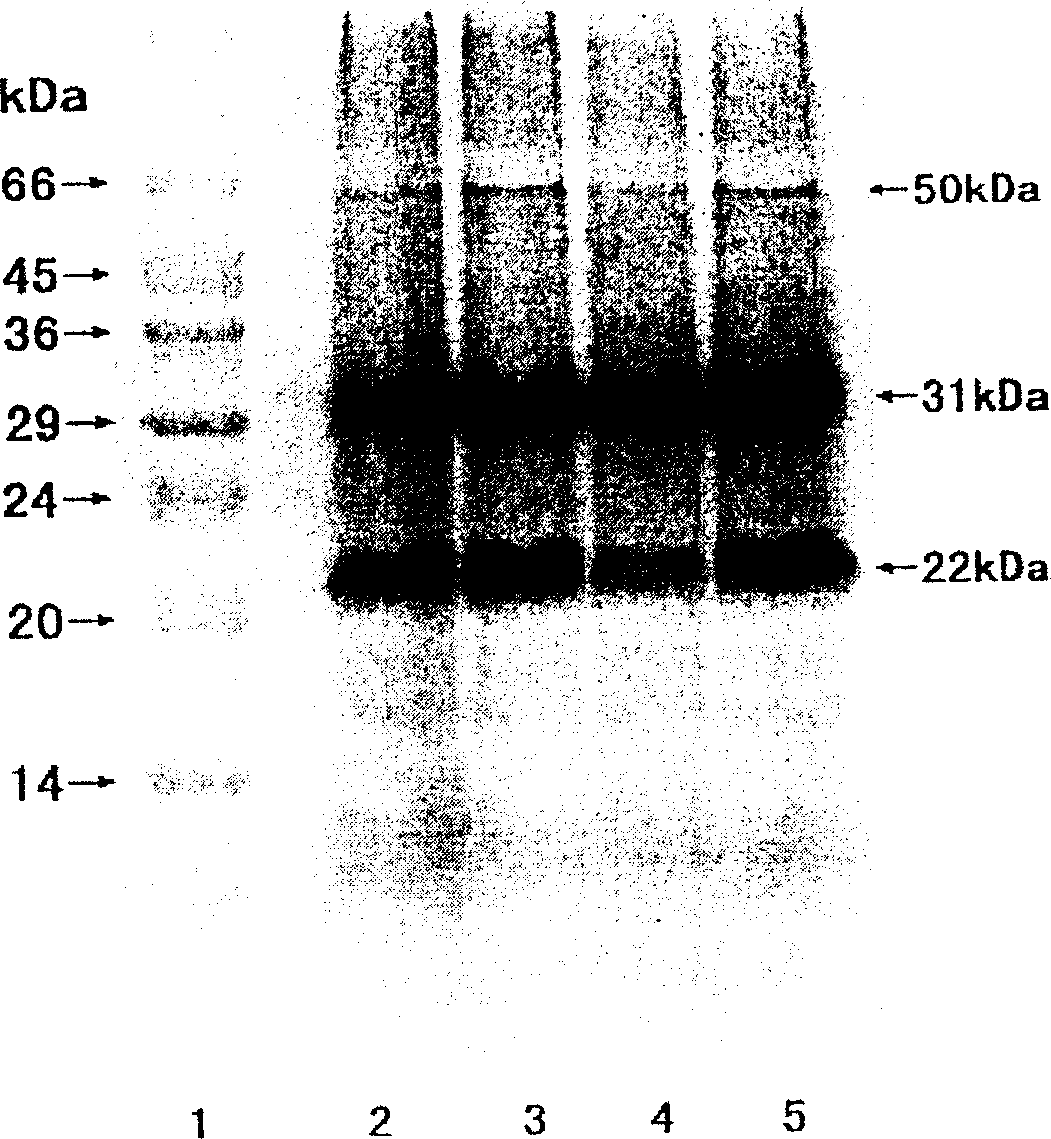

[0028] This example takes Yufeng sweet potato as an example to illustrate the effect of dialysis treatment on the protein content in the product during the extraction process.

[0029] Divide the filtrate of Yufeng sweet potato after starch removal into two parts, one part is adjusted to pH 4 with hydrochloric acid, the other part is adjusted to pH 4.5, and the precipitate after centrifugation is diluted with 10 times of distilled water, and then divided into two parts, one part of the solution Freeze-drying is directly carried out, and another part of the solution is put into about 30 times distilled water for dialysis, and then freeze-dried to obtain respective dry extracts. The protein content of these extracts was determined by the protein quantification methods of Markwell et al [Markwell M.A.K. Anal. Biochem. , protein standard sample bovine serum was purchased from Sigma, USA. Result (see table 1) shows that no matter pH 4 or pH 4.5, protein content in the sample after...

Embodiment 3

[0032] In this embodiment, in order to screen the most suitable sweet potato varieties, the protein content of different sweet potato varieties was determined by the Kjeldahl method. Result (table 2) shows that protein content is obviously different among different kinds of sweet potatoes, and protein content is the highest in red winter sweet potato, which is 2.64 times of Yufeng sweet potato. Therefore, when preparing sweet potato protein extract, the sweet potato variety with high protein content is selected. very important.

[0033] The specific experimental method is as follows: Weigh 2 g of sweet potato and place it in a digestion tube, add 12 ml of concentrated sulfuric acid, digest at 420° C., and take 1.5 hours to measure the protein content in sweet potato with a Kjeldahl nitrogen analyzer (KIELTECANALYSISER Kjeldahl nitrogen analyzer from Foss, Sweden). ).

[0034] Variety name and source

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com