Multi-channel nerve rehabilitating tube, its preparation process and dedicated mold

A nerve repair and multi-channel technology, applied in the field of preparation of multi-channel nerve repair catheters, can solve problems such as easy separation, unfavorable axons passing through the catheter, complicated operation, etc., achieve stable performance, easy popularization and application, and simple operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) First utilize conventional methods, such as the method of Chinese patent application ZL 02149086.4, to prepare chitosan round tubes with an inner diameter of 1 to 5 mm and a wall thickness of 0.2 to 1.0 mm;

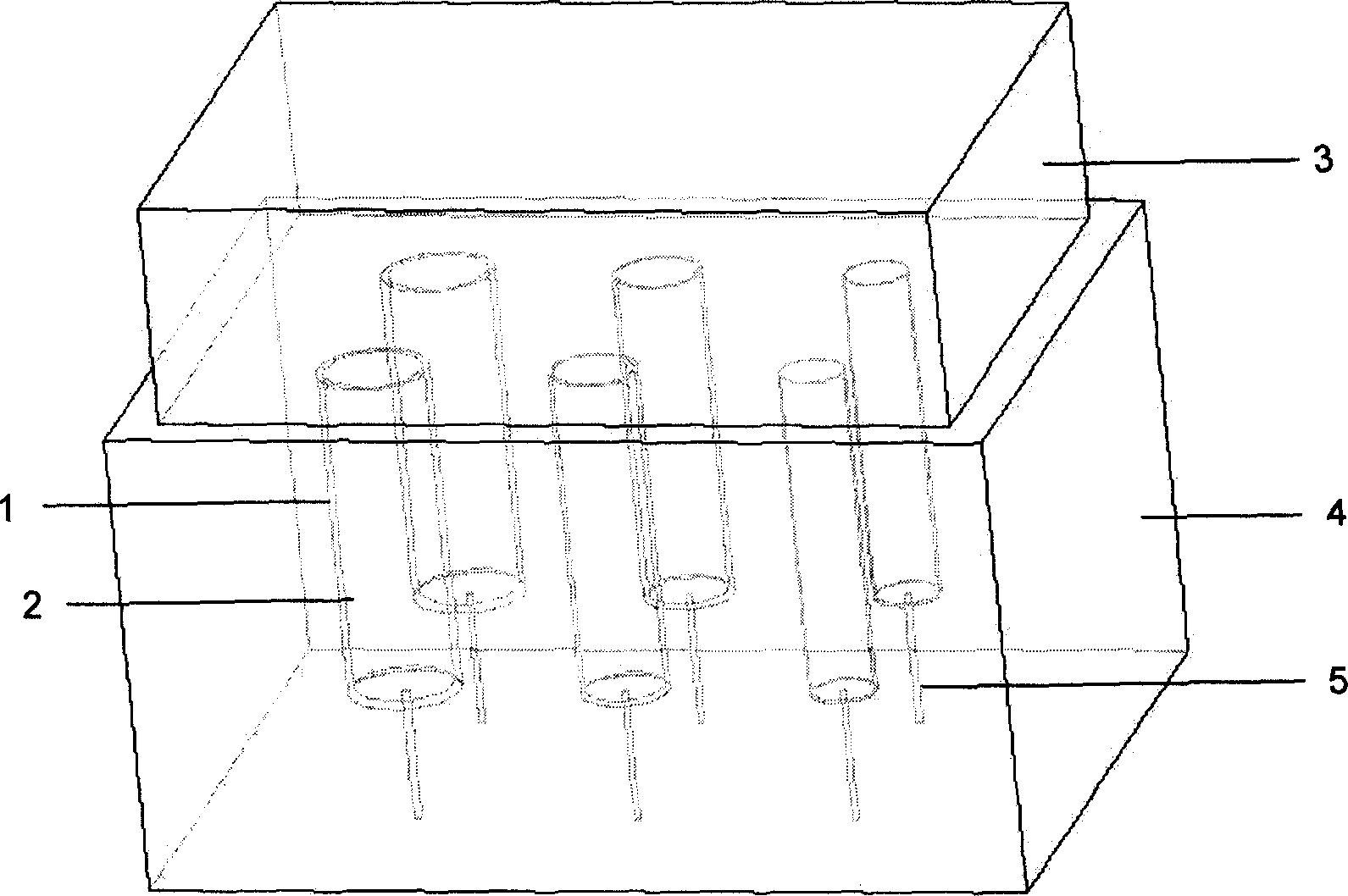

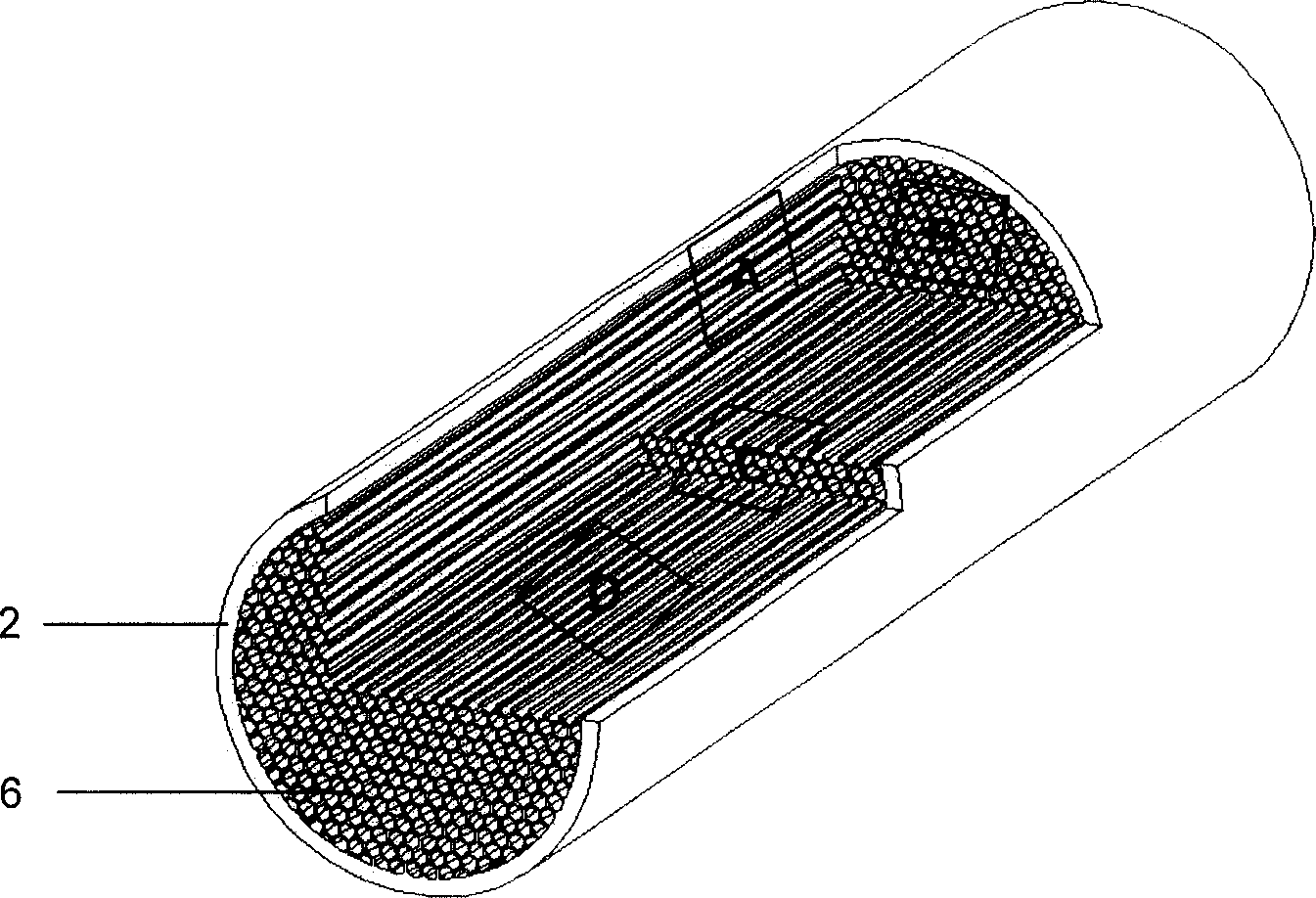

[0022] 2) As attached figure 1 As shown, the chitosan round tube 2 of 5 cm long different diameters is inserted in the hole 1 of corresponding diameter on the mold base 4, injects 4% (w / v) chitosan solution (with 0.2mol / L acetic acid solution). Quickly cover the -20°C pre-cooled stainless steel cover plate 3 on it, put it in the -20°C refrigerator for more than 12 hours, then remove the stainless steel cover plate 3, take out the round tube containing the ice crystal column, put it in a low-temperature container, and freeze-dry Freeze-dry in the machine (the main temperature is about -40 ℃) for more than 24 hours;

[0023] 3) Soak the freeze-dried specimen in step 2) in an aqueous sodium hydroxide solution with a concentration of 2% (w / v) for 30 minutes, take ...

Embodiment 2

[0026] 1) First utilize conventional methods, such as the method of Chinese patent application ZL 02149086.4, to prepare chitosan round tubes with an inner diameter of 1 to 5 mm and a wall thickness of 0.2 to 1.0 mm;

[0027] 2) As attached figure 1As shown, the chitosan round pipe 2 of different diameters with 3cm length is inserted in the hole 1 of corresponding diameter on the mold base 4, then in the chitosan round pipe, inject 4% (w / v) chitosan solution (with 0.2 mol / L acetic acid solution) and 10% gelatin aqueous solution, the mass ratio of the two is 1:1. Quickly cover the -80°C pre-cooled stainless steel cover plate 3 on it, put it in the -80°C refrigerator for more than 12 hours, then remove the stainless steel cover plate 3, take out the round tube containing the ice crystal column, put it in a low-temperature container, and freeze-dry Freeze-dry in the machine (the main temperature is about -40 ℃) for more than 24 hours;

[0028] 3) Soak the freeze-dried specimen ...

Embodiment 3

[0031] 1) First utilize conventional methods, such as the method of Chinese patent application ZL 02149086.4, to prepare chitosan round tubes with an inner diameter of 1 to 5 mm and a wall thickness of 0.2 to 1.0 mm;

[0032] 2) As attached figure 1 As shown, 1 cm long chitosan round tubes 2 of different diameters were inserted into holes 1 of corresponding diameters on the mold base 4, and then injected into the chitosan round tubes 2 in combination with bFGF (20 μg / L), VEGF (20 μg / L ) mixed solution gel of heparin and chitosan, the final concentration of heparin is 1%, and the final concentration of chitosan is 3%. Quickly cover the -80°C pre-cooled stainless steel cover plate 3 on it, put it in the -80°C refrigerator for more than 12 hours, then remove the stainless steel cover plate 3, take out the round tube containing the ice crystal column, put it in a low-temperature container, and freeze-dry Freeze-dry in the machine (the main temperature is about -40 ℃) for more tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com