Self-ignite preparation method of spherical nanometer Yttrium europium silicate fluorescent powder

A technology of yttrium silicate and phosphor powder, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of unreported self-combustion method, and achieve the effects of small particle size distribution, high bulk density and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

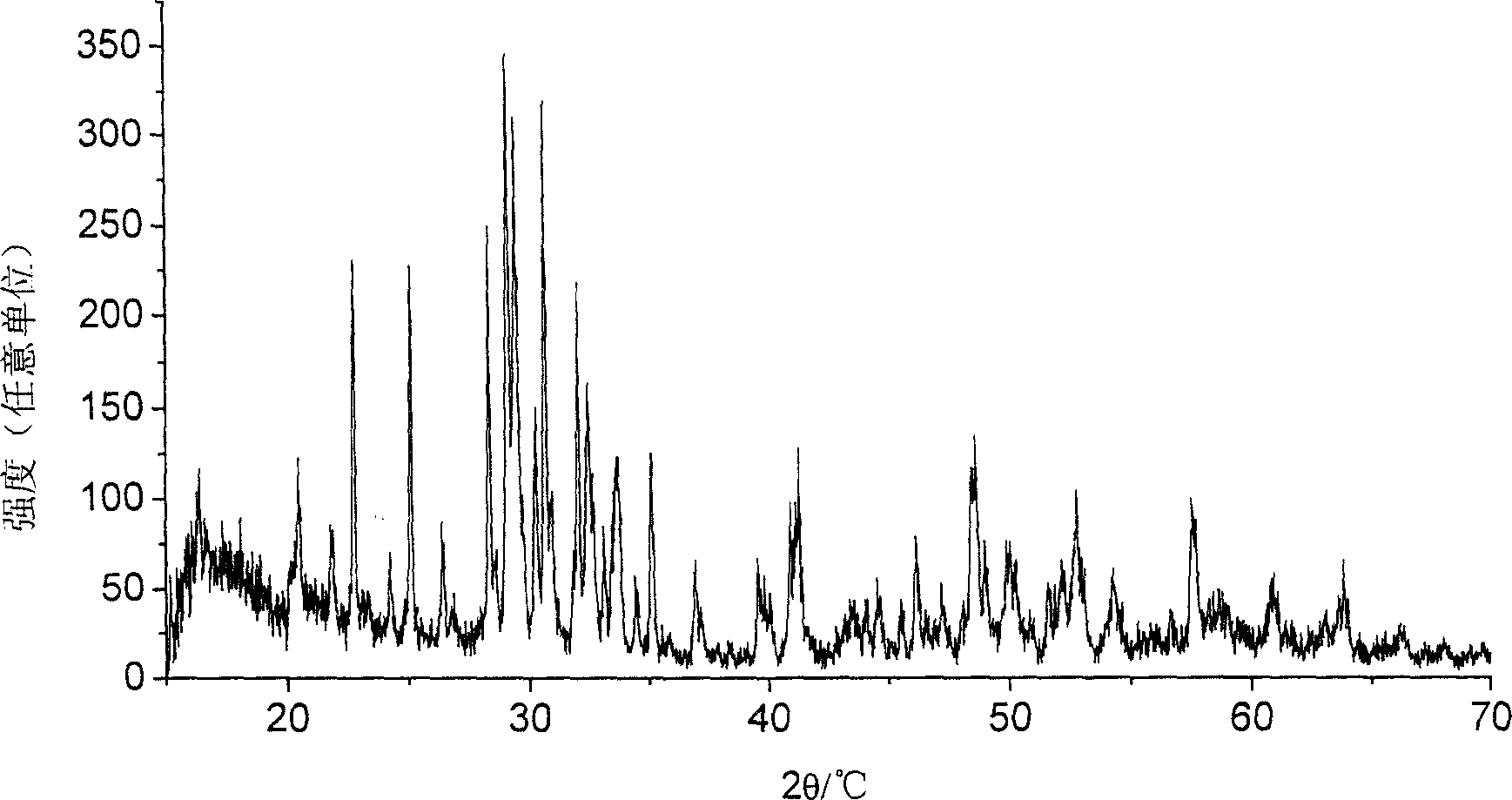

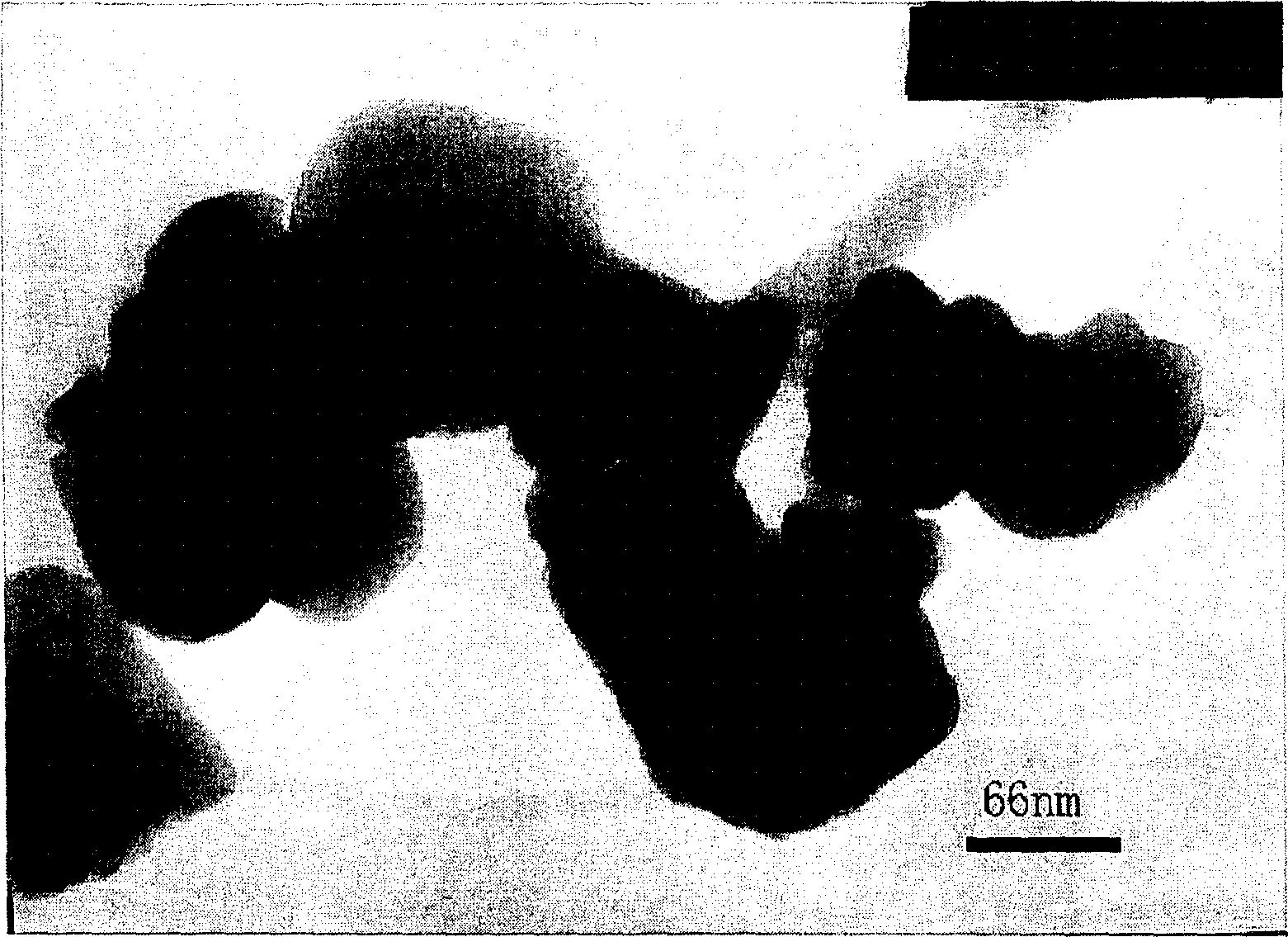

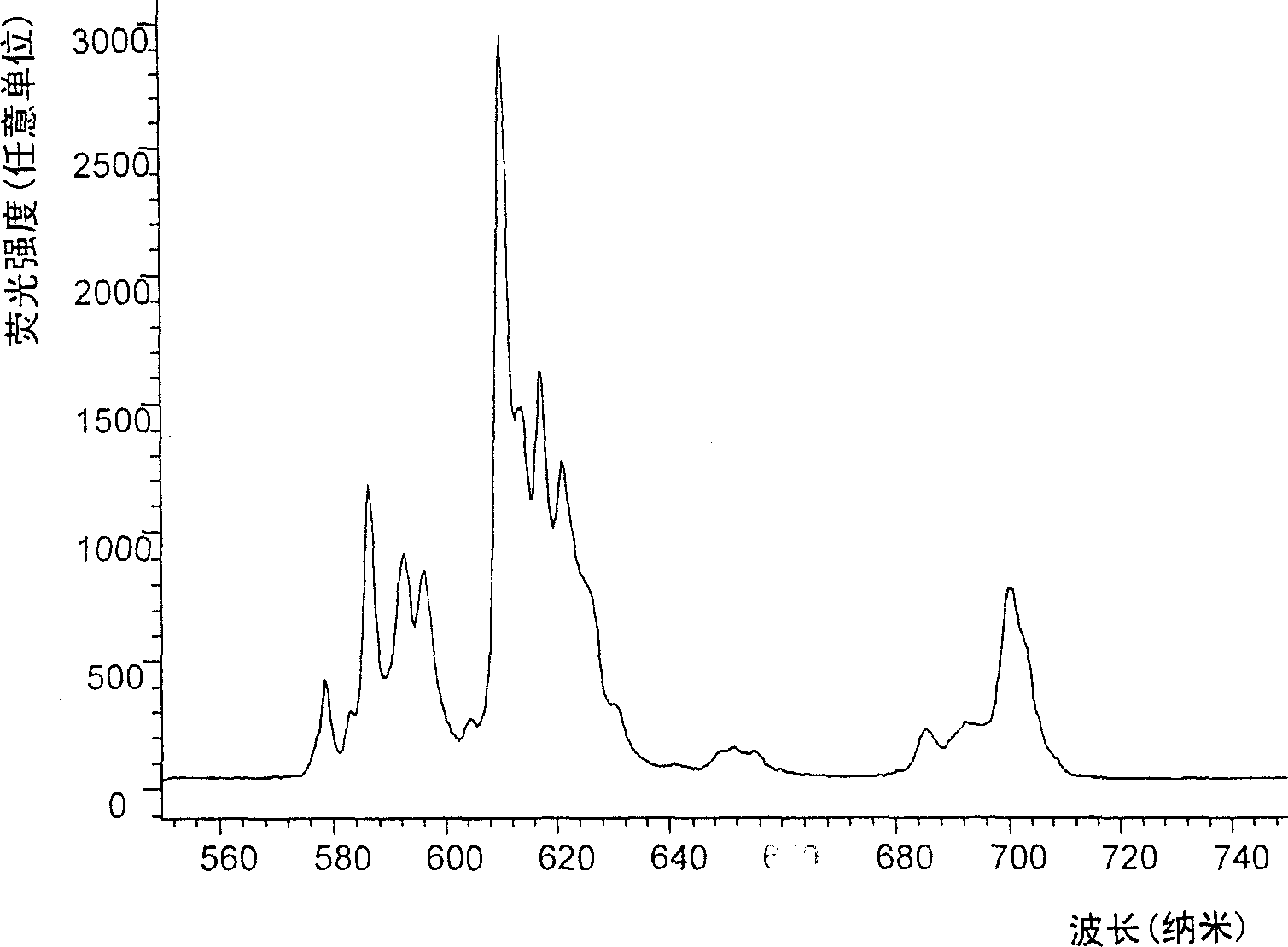

[0021] A self-combustion preparation method of spherical nano-yttrium europium silicate fluorescent powder, 5% Eu, Y:Si=2.3:1, Si:Gly=1:5, furnace temperature 700°C, calcination 1300°C-3h.

[0022] Weigh 1.5944 grams of Si (OC 2 h 5 ) 4 , followed by adding 1.7276 g C 2 h 6 O and 0.2701 g H 2 O, and add nitric acid HNO dropwise 3 , adjust the pH value to 2-3, and form a uniform transparent sol after stirring for 40 minutes. Then add 2.8160 grams of Gly, and then dropwise add 16.4ml of Y (NO 3 ) 3 (0.001mol / ml), 4.3ml of Eu(NO 3 ) 3 (0.0002mol / ml) solution, after fully stirring for 40min, heated in a water bath at 80°C for 1.5h to form a transparent gel. Put it into a crucible and continue heating in a muffle furnace at 700°C. When the water is evaporated to dryness, the temperature rises sharply, and after spontaneous combustion, it continues to burn until all reactants are completely reacted, and the collected product is nano-amorphous powder Eu:Y 2 SiO 5 . In o...

Embodiment 2

[0030]A self-combustion preparation method of spherical nano-yttrium europium silicate fluorescent powder, 40% Eu, Y:Si=2:1, Si:Gly=1:5, furnace temperature 700°C, calcining 1100°C-3h.

[0031] Weigh 1.7032 grams of Si (OC 2 h 5 ) 4 , followed by adding 1.8583 g C 2 h 6 O and 0.3019 g H 2 O, and add nitric acid HNO dropwise 3 , adjust the pH value to 2-3, and form a uniform transparent sol after stirring for 40 minutes. Then add 3.0033 grams of Gly, and then dropwise add 14.4ml of Y (NO 3 ) 3 (0.001mol / ml), 8ml of Eu(NO 3 ) 3 (0.0002mol / ml) solution, stirred for 40min, heated in a water bath at 80°C for 1.5h, then continued to heat in a muffle furnace at 700°C until the reactants were completely reacted, and the obtained product was collected for high-temperature calcination. Same as in Example 1, the final holding temperature is 1100° C., the holding temperature is 3 hours, and the average grain size of the polycrystalline powder is 39 nm.

Embodiment 3

[0033] A self-combustion preparation method of spherical nano-yttrium europium silicate fluorescent powder, 5% Eu, Y: Si = 2.3: 1, Si: Gly = 1: 3, furnace temperature 700 ° C, calcination 1500 ° C - 3h.

[0034] Weigh 1.0598 grams of Si (OC 2 h 5 ) 4 , followed by adding 1.1544 g C 2 h 6 O and 0.1801 g H 2 O, and add nitric acid HNO dropwise 3 , adjust the pH value to 2-3. After fully stirring for 40 minutes, a uniform transparent sol was formed. Then add 1.1265 grams of Gly, and then drop 8.5ml of Y (NO 3 ) 3 (0.001mol / ml), 11.5ml of Eu(NO 3 ) 3 (0.0002mol / ml) solution, after stirring for 40min, heat in 80 DEG C of water baths for 1.5h, then heat up and spontaneously ignite in a muffle furnace of 700 DEG C, the following is the same as Example 1, and the final insulation temperature is 1500 DEG C, and it is incubated for 3 hours, The average grain size of the polycrystalline powder is 103nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com