Method for quick detection of formaldehyde in food

A detection method, formaldehyde technology, applied in the field of formaldehyde detection, can solve the problems affecting the accuracy and operability of test results, unsatisfactory precipitation effect, background interference, etc., achieve the goal of shortening the filtration time, good effect and ensuring accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

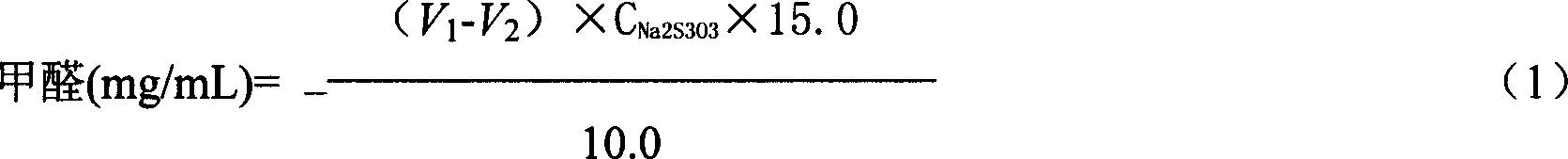

Image

Examples

Embodiment 1

[0039] 1) Prepare reagents:

[0040] Prepare protein precipitation reagent A: put 10g of lead acetate in the volumetric flask, add 100mL of distilled water; Shake until fully dissolved; prepare color developer: put 25g ammonium acetate, 3mL glacial acetic acid, 0.3mL acetylacetone into the volumetric flask; add 100mL distilled water, shake gently until fully dissolved;

[0041] 2) Prepare the sample solution to be tested:

[0042] Chopped Shuifacai sample, weighed 10.0g into a 100mL volumetric flask, added distilled water to 60mL, tightly closed the lid, left for (60±5)min, shook the flask every 5min, added 10.0mL protein precipitation reagent A, lightly Shake gently, then add 10.0mL protein precipitation reagent B, after shaking gently, dilute to 100mL mark with distilled water, shake well, let stand, and filter with medium-speed filter paper;

[0043] The above-mentioned sample to be tested is detected according to the steps in the above-mentioned detection method.

Embodiment 2

[0045] 1) Prepare reagents:

[0046] Prepare protein precipitation reagent A: put 30g of lead acetate in the volumetric flask, add 100mL of distilled water; Shake until fully dissolved; prepare color developer: put 25g ammonium acetate, 3mL glacial acetic acid, 0.5mL acetylacetone into the volumetric flask; add 100mL distilled water, shake gently until fully dissolved;

[0047] 2) Prepare the sample solution to be tested:

[0048] The sea cucumber samples made of distilled water were smashed with a mash machine, weighed 5.0g into a 100mL volumetric flask, added distilled water to 60mL, closed the lid tightly, left for (60±5)min, shake the flask every 5min, and added 10.0mL of protein precipitation Reagent A, shake gently, then add 10.0mL protein precipitation reagent B, after shaking gently, dilute to 100mL mark with distilled water, shake well, let stand, filter with medium-speed filter paper;

[0049] The above-mentioned sample to be tested is detected according to the ste...

Embodiment 3

[0051] 1) Prepare reagents:

[0052]Prepare protein precipitation reagent A: put 15g of lead acetate in the volumetric flask, add 100mL of distilled water; Shake until fully dissolved; prepare a color developer: put 25g ammonium acetate, 3mL glacial acetic acid, 0.4mL acetylacetone into the volumetric flask; add 100mL distilled water, shake gently until fully dissolved;

[0053] 2) Prepare the sample solution to be tested:

[0054] Weigh 10.0g of flour sample into a 100mL volumetric flask, add distilled water to 60mL, close the lid tightly, let it stand for (60±5)min, shake the flask every 5min, add 10.0mL protein precipitation reagent A, shake gently, and then Add 10.0mL protein precipitation reagent B, after shaking gently, dilute to 100mL mark with distilled water, shake well, let stand, and filter with medium-speed filter paper;

[0055] The above-mentioned sample to be tested is detected according to the steps in the above-mentioned detection method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com