Zirconium dioxide nano powder material preparation method

A technology of nanopowder and zirconia, which is applied in nanostructure manufacturing, zirconia, nanotechnology, etc., can solve the problems of wide particle size range, serious agglomeration phenomenon, and inability to meet the needs of zirconia all-ceramic repair materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

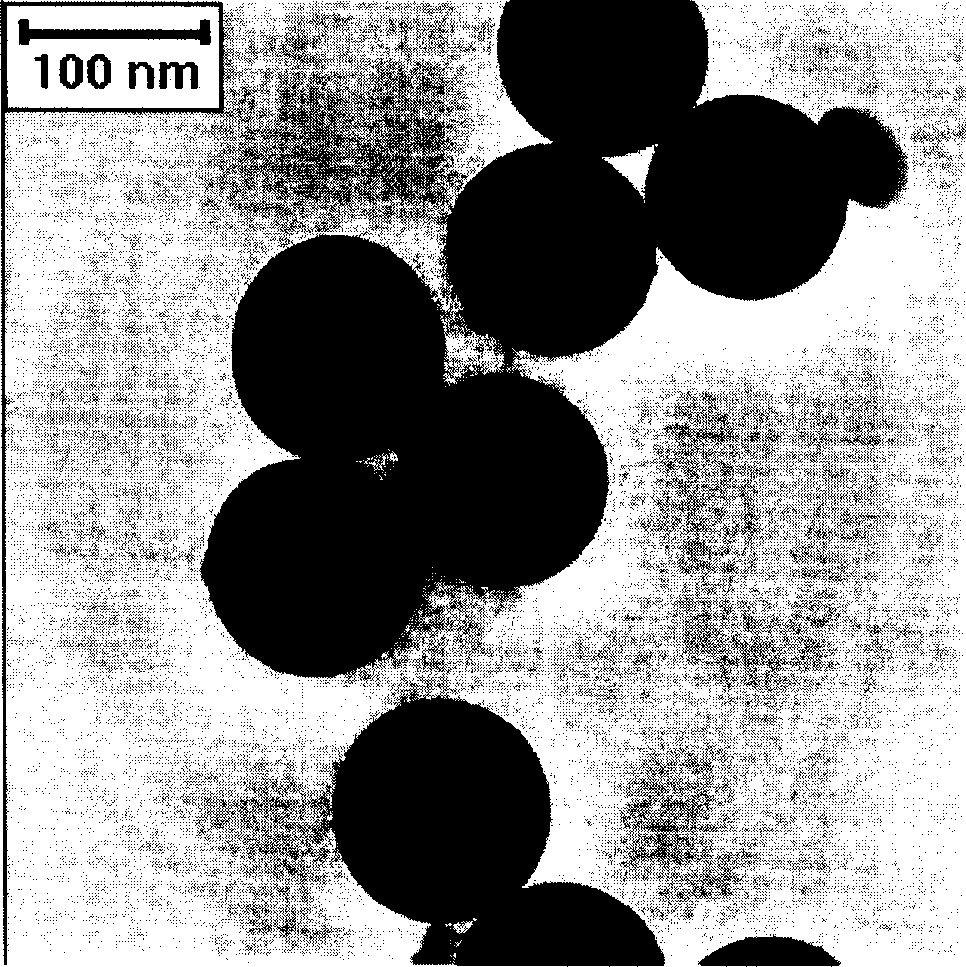

Image

Examples

Embodiment 1

[0039] Get 300ml of organic solvent n-heptane, add 1.2g of oil-soluble surfactant Span in this organic solvent, make organic matter solution, and be divided into two parts, add 2ml concentration in a part and be the zirconium salt ZrO of 0.75mol / L (Ac) 2 solution, and 5 ml of ammonia solution with a concentration of 10 mol / L was added to the other part to prepare two solutions. Each of the two solutions was subjected to high-speed shear emulsification and dispersion for 10 minutes, then the two solutions were mixed, and ultrasonic dispersion was carried out at room temperature for 30 minutes at a frequency of 90 KHz. The obtained product was distilled on a distillation machine, the distillation temperature was 115°C, and the distillation time was 3h; after distillation, the product was mixed with the two solutions, and ultrasonically dispersed at room temperature for 35min at a frequency of 150KHz. The obtained product was distilled on a distillation machine, the distillation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com