LED structure

A technology of light-emitting diodes and light-emitting layers, which is applied to electrical components, circuits, semiconductor devices, etc., and can solve problems such as increased stress in multiple quantum well structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

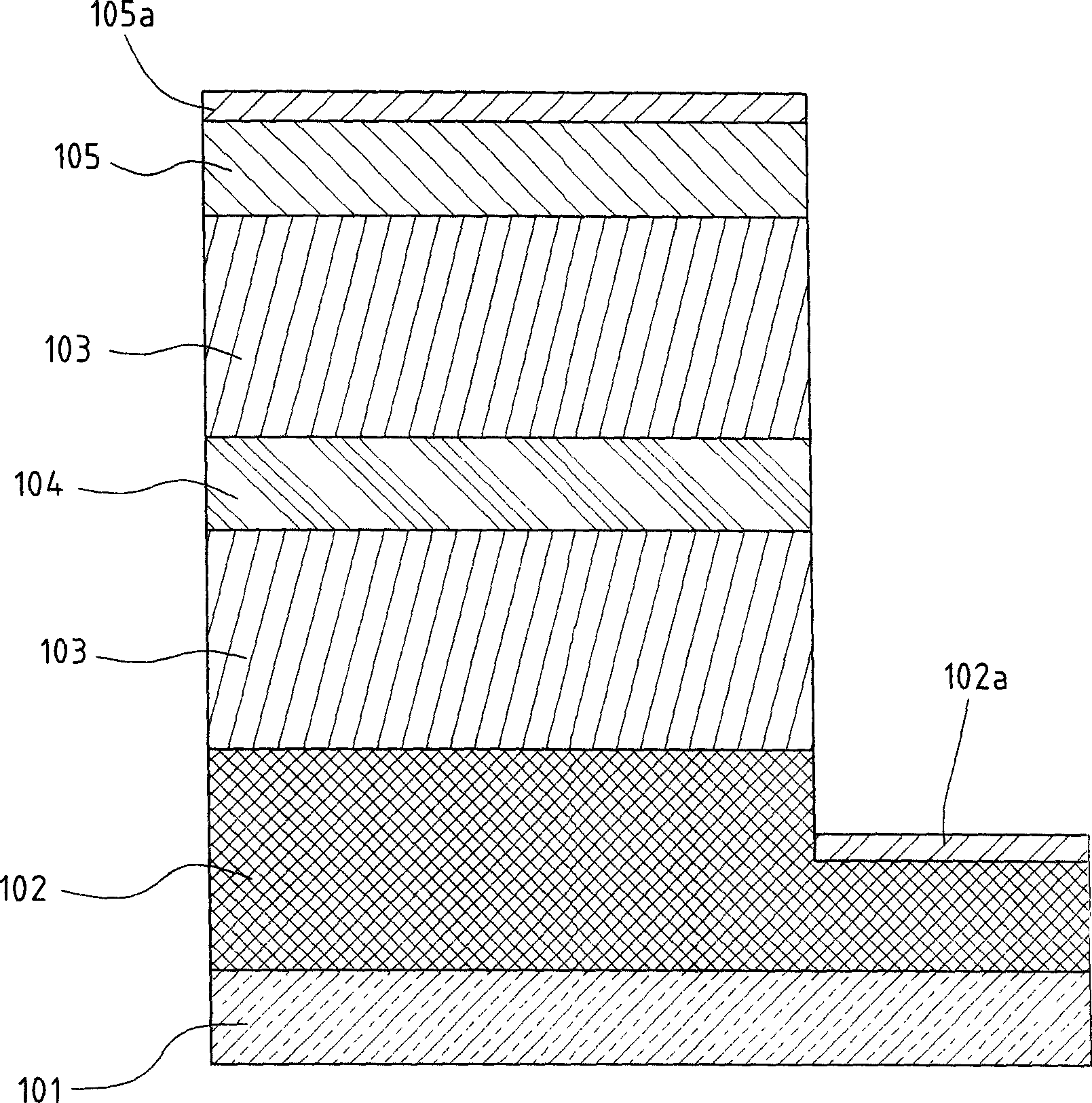

[0015] refer to figure 1 As shown, the first embodiment of the LED structure of the present invention includes: a substrate 101 , an N-type contact layer 102 , a barrier layer 103 , a light-emitting layer 104 and a P-type contact layer 105 .

[0016] The substrate 101 can be made of C-Plane or R-Plane or A-Plane alumina single crystal (Sapphire), or made of SiC (6H-SiC or 4H-SiC), Si, ZnO, GaAs or spinel Stone (MgAl 2 o 4 ), or a single crystal oxide whose lattice constant is close to that of a nitride semiconductor, in which Sapphire or SiC is generally used to form an N-type contact layer 102 on the substrate 101 . In addition, the N-type contact layer 102 is formed of N-type gallium nitride (GaN) material, an N-electrode layer 102 a in ohmic contact is formed on one side, and a barrier layer 103 is formed on the upper side.

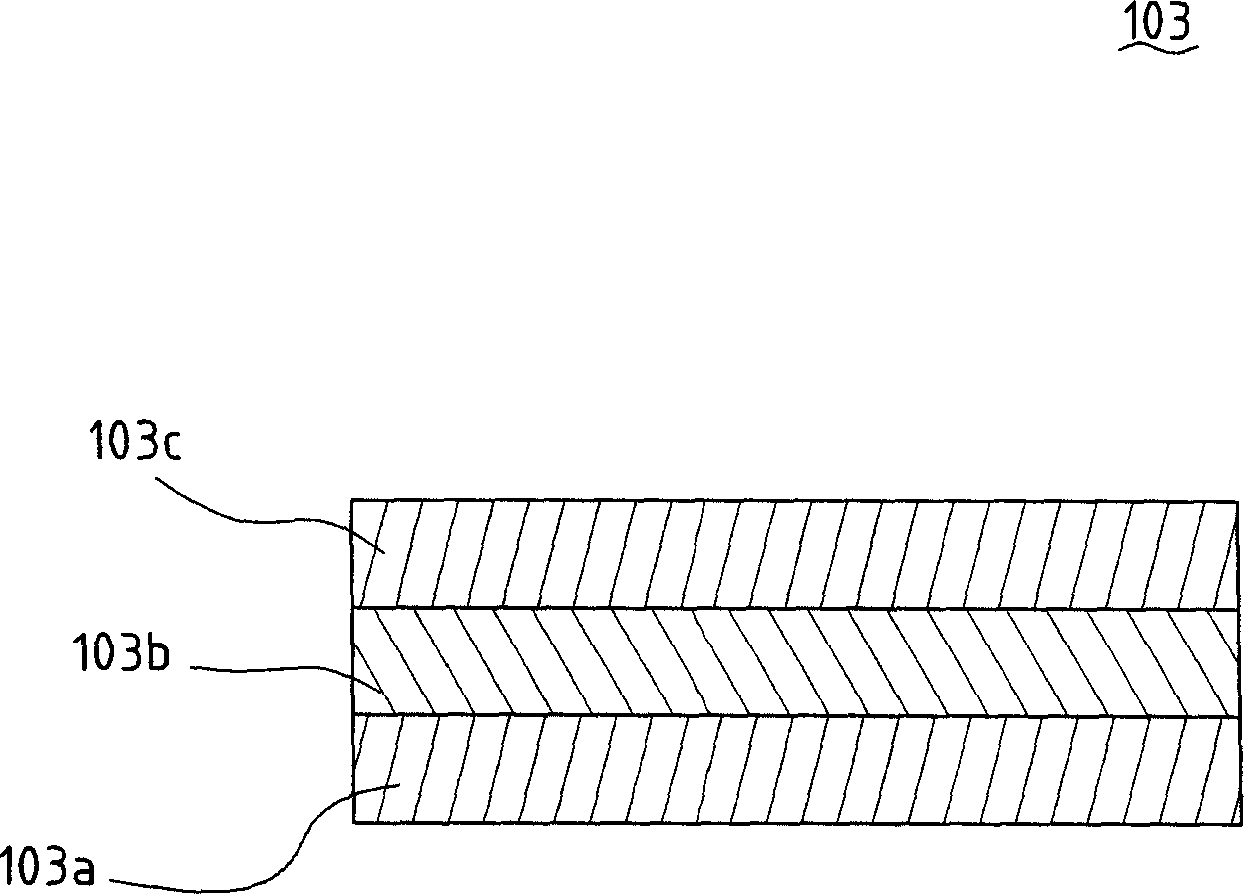

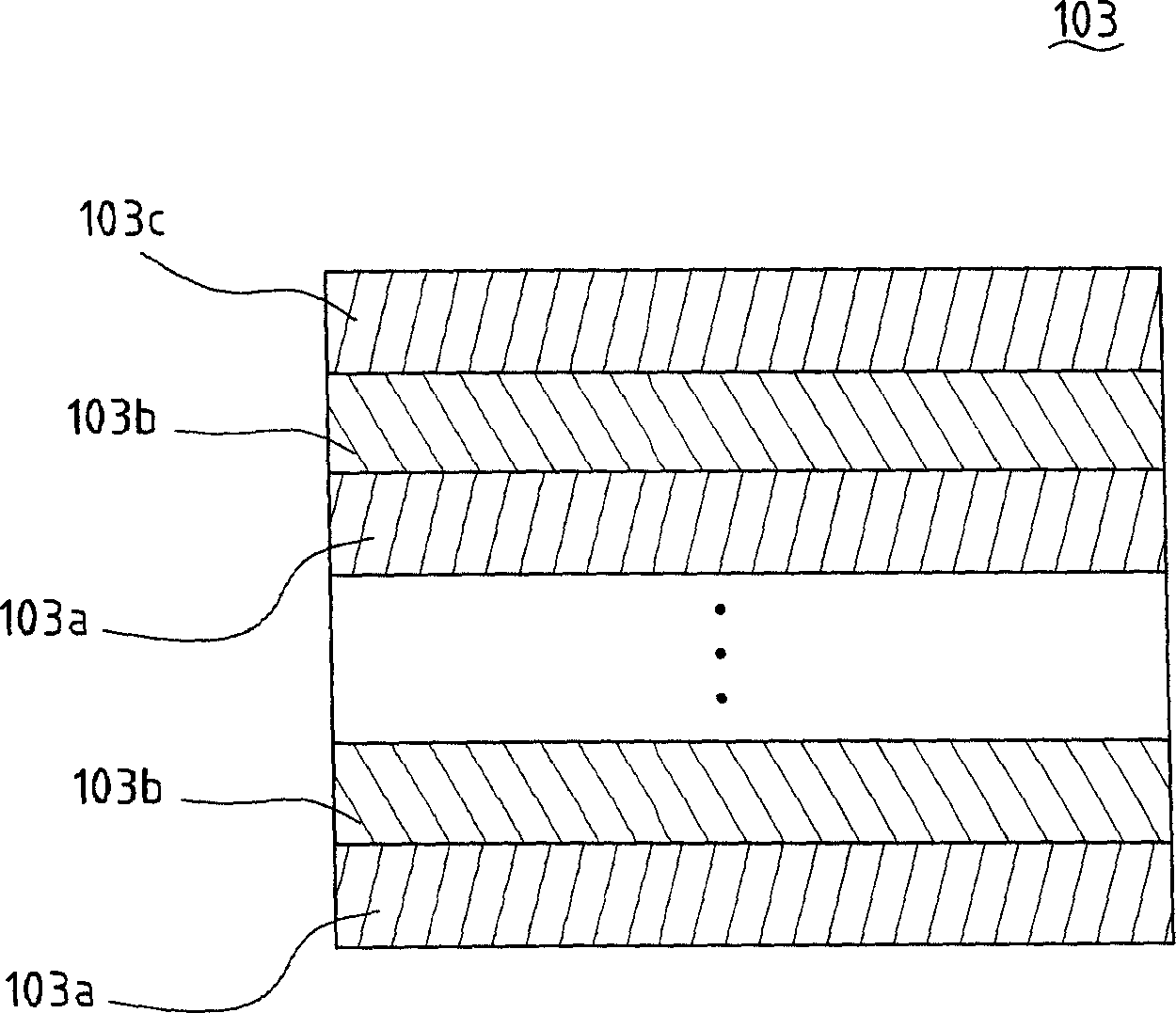

[0017] refer to figure 2 As shown, the barrier layer 103 includes: a first AlInGaN layer 103a, which is grown on the N-type contact layer 102 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com