Jelly spinning polyethylene/epoxy resin composite fiber and its preparing method

A technology of epoxy resin and composite fiber, applied in the direction of wet spinning, fiber chemical characteristics, conjugated synthetic polymer artificial filament, etc., can solve the problems of UHMWPE performance degradation, complicated process, and inability to form force, etc., to achieve Good heat resistance and creep resistance, high heat deflection temperature, and the effect of improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

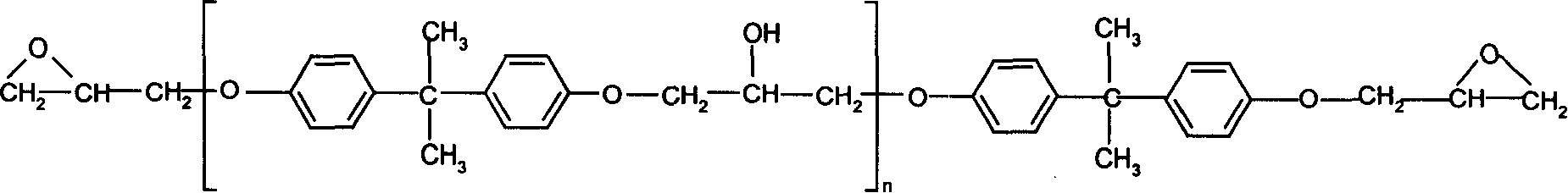

[0063] Weigh 2g molecular weight M w >10 6 UHMWPE and 0.1g bisphenol A epoxy resin E44, put both in a vacuum oven for 48 hours at the same time; dry UHMWPE and bisphenol A epoxy resin E44 and 0.02g curing agent and 0.01g antioxidant , 0.002g auxiliary antioxidant mixed evenly;

[0064] Heating range (°C)

0~100

100~110

110~120

120~130

130~190

Holding time (min)

10

30

30

30~60

150

[0065] (3) Gel spinning: the fully dissolved UHMWPE / epoxy resin composite solution is spun by a conventional gel spinning method to obtain the fiber of the present invention.

[0066] The spinning temperature of said jelly spinning method is 180°C, and the prepared gel filaments are subjected to extraction, thermal drawing three times, etc. to obtain the fiber of the present invention. The performance test results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com