Method for preparing toluene disproportionation zeolitic catalyst with increased para-selectivity

A zeolite catalyst, toluene disproportionation technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of cumbersome preparation process, low conversion rate, expensive solvent used, etc., and achieve simple process and good effect. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 (comparative example)

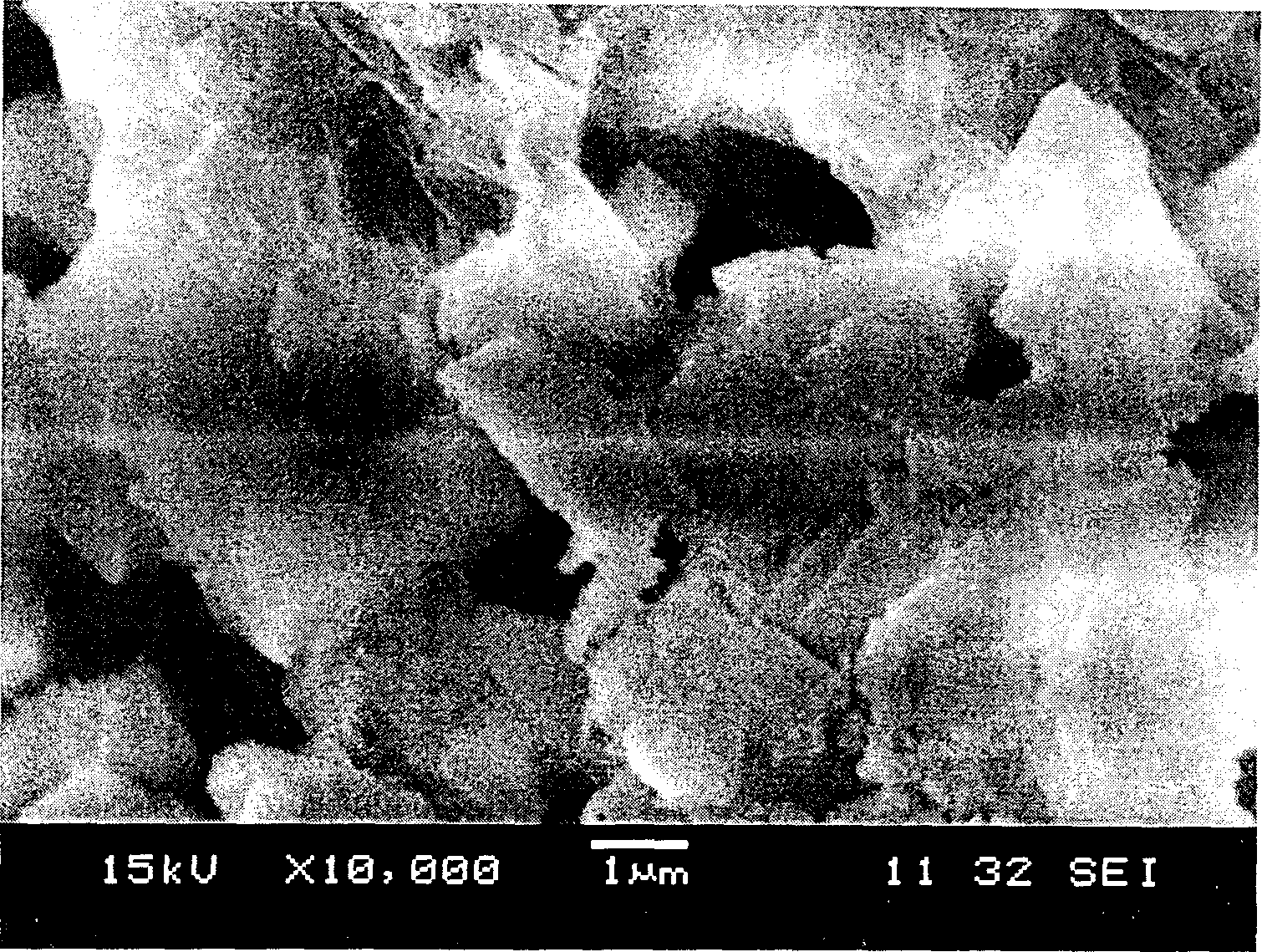

[0041] In this example, the method of the present invention is used to modify the catalyst by chemical liquid deposition silicon.

[0042] The hydrogen type ZSM-5 zeolite powder (Nankai University Catalyst Factory) that the silicon-aluminum ratio is 38 is mixed with sheepsweet in a weight ratio of 80:20, and then the kale powder that is 4 weight parts is added therein, and fully mixed until Mix well, add 5 parts of water, knead and extrude.

[0043] The solid obtained by extruding was air-dried, dried at 110° C. for 3 hours, and calcined at 550° C. for 3 hours to obtain catalyst A.

[0044] The toluene disproportionation reaction is carried out on a high-pressure micro-reaction device. Take 1 gram of catalyst A and fill it in the middle section of a stainless steel reaction tube with a length of 500 mm and an internal diameter of 14 mm, and fill quartz sand up and down. Pure toluene feed, mass space velocity...

Embodiment 2-5

[0054] The following examples examine the effect of deposition times on the para-selectivity of catalysts.

[0055] Take 10 grams of the above-mentioned molded catalyst A particles, add cyclohexane solvent at room temperature (20° C.) at a ratio of liquid-solid mass ratio of 8:1, then add 2 grams of tetraethyl orthosilicate, and carry out chemical liquid phase under stirring conditions. After deposition reaction for 10 hours, drying and aging at 110°C for 5 hours, the temperature was raised to 550°C in a muffle furnace at 2°C / min and calcined for 4 hours to obtain catalyst B.

[0056] Take 5 grams of catalyst B particles, and add 1 gram of tetraethyl orthosilicate under the same conditions for deposition, aging and roasting, and the obtained catalyst is C.

[0057] Take 5 grams of shaped catalyst A particles, according to the modification conditions of catalyst B, add 2 grams at a time for silicon modification, and obtain catalyst D. The catalyst of embodiment 2-5 carries out...

Embodiment 6-11

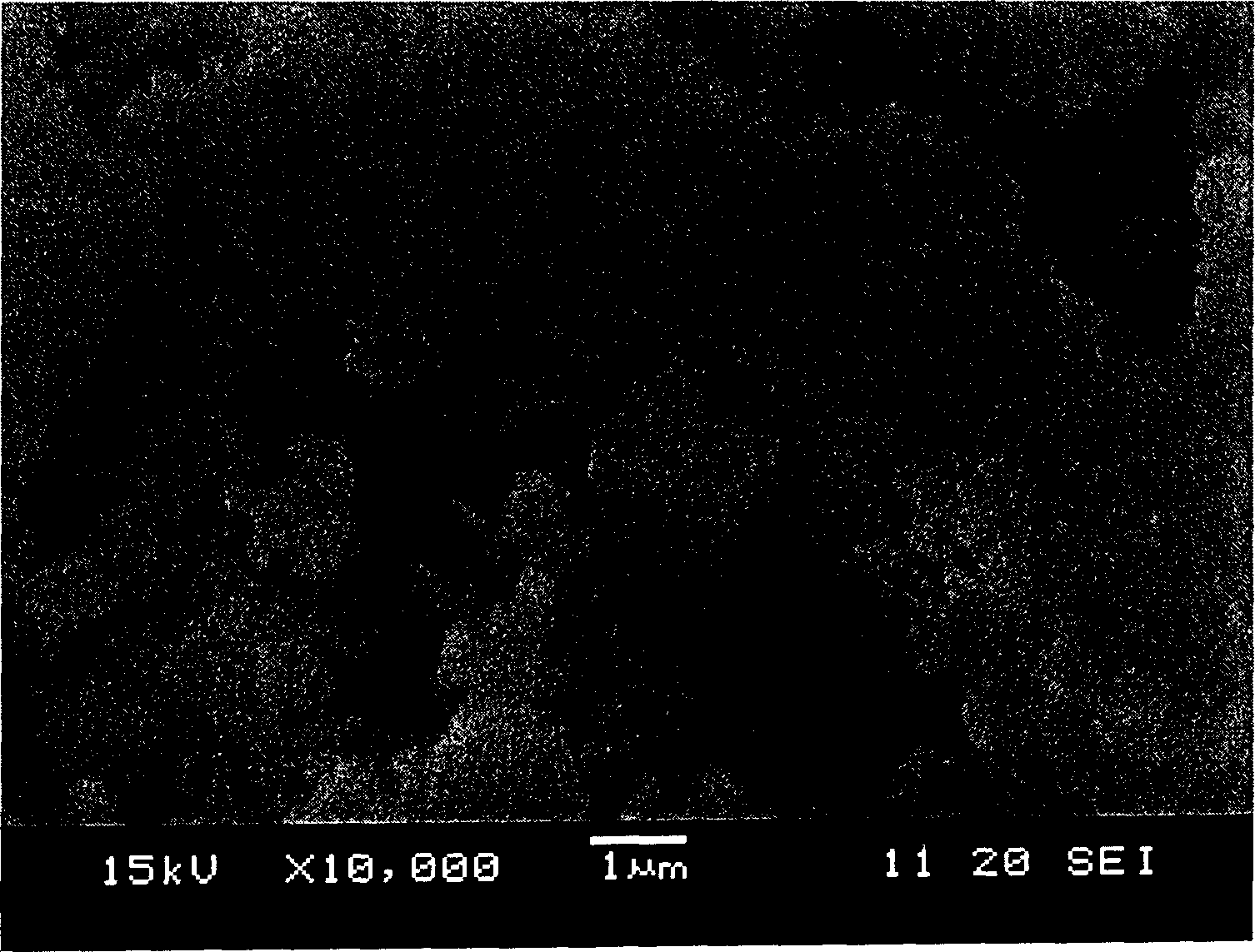

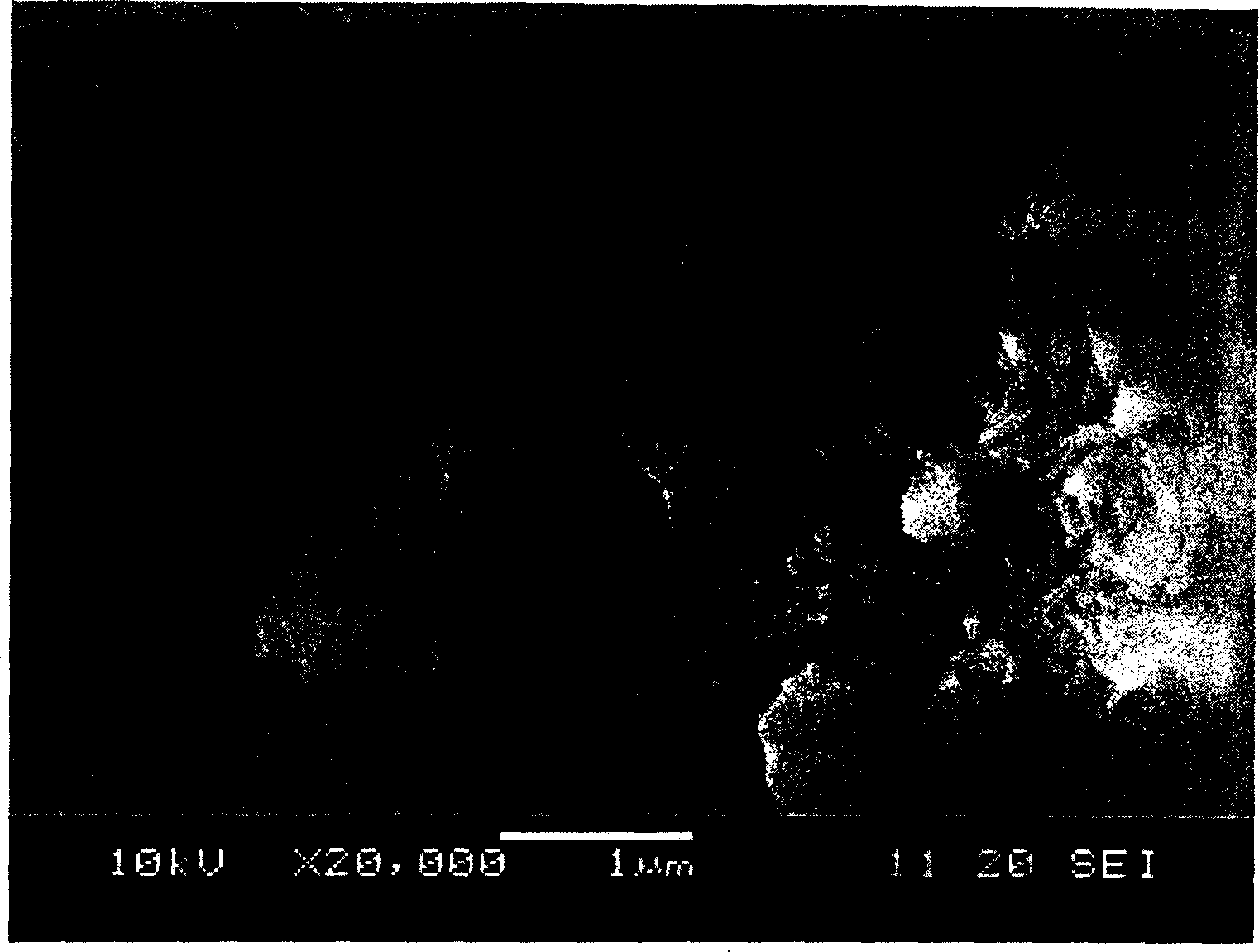

[0061] The following examples investigate the effects of different organic acid solutions on the active components of zeolite on catalyst activity and chemical liquid phase deposition of tetraethyl orthosilicate

[0062] Take 20 grams of catalyst A particles, add 160 grams of oxalic acid aqueous solution with a concentration of 2 mol / L, reflux and stir at 80 ° C for 2 hours, then filter, wash and dry to obtain catalyst E. Then take 15 grams of catalyst E, modify it with 2.25 grams of tetraethyl orthosilicate by the method described in the examples, and then obtain catalyst F through drying, aging and roasting.

[0063] Also take 10 grams of catalyst A particles, add 40 grams of citric acid aqueous ethanol solution with a concentration of 2 mol / L, reflux and stir at 80° C. for 2 hours, then filter, wash and dry to obtain catalyst G. Another 8 grams of catalyst G was taken, modified with 1.2 grams of tetraethyl orthosilicate by the method described in the examples, and then drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com