Fastening ring made of wide thermal hysteresis Ti-Ni-based shape-memory alloy, preparation method and application thereof

A memory alloy and fastening ring technology, applied in the field of shape memory alloys, can solve the problems that TiNiNb alloy cannot meet the demand, cannot bear large diameter expansion deformation, and is inconvenient to use, and achieves light weight, good tightness, and installation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Vacuum induction furnace is used for smelting, the ingot is soaked at 800℃~1000℃ for 3 hours, hot forged at 800℃~900℃ to form a φ40mm rod, and then 800℃~900℃ hot rolled into a φ20mm rod, after 850 ℃, after 30 minutes air-cooled to room temperature, the car was made into a sample, and the mechanical properties were measured at -55 ℃, room temperature and 300 ℃ respectively. The results are listed in Table 2. In the table σ 0.2 is the yield strength, and δ is the elongation. After some samples were pre-deformed at -65°C, the shape recovery strain εr and A's temperature were measured. The results are also listed in Table 2. In the table, εt is the total pre-deformation amount, and εr is the shape recovery strain.

[0045] implement

Embodiment 2

[0047] Vacuum induction furnace is used for smelting, the ingot is soaked at 900°C for 3 hours, hot-forged at 840°C to form a φ40mm bar, and then hot-rolled at 860°C to form a φ20mm bar, after 30 minutes at 850°C, the furnace is cooled to room temperature , the samples were made by car, and the mechanical properties were measured at -55°C, room temperature and 300°C respectively, and the results are listed in Table 2. In the table, σ 0.2 is the yield strength, and δ is the elongation. After some samples were pre-deformed at -65°C, the shape recovery strain εr and A's temperature were measured. The results are also listed in Table 2. In the table, εt is the total pre-deformation amount, and εr is the shape recovery strain.

[0048] implement

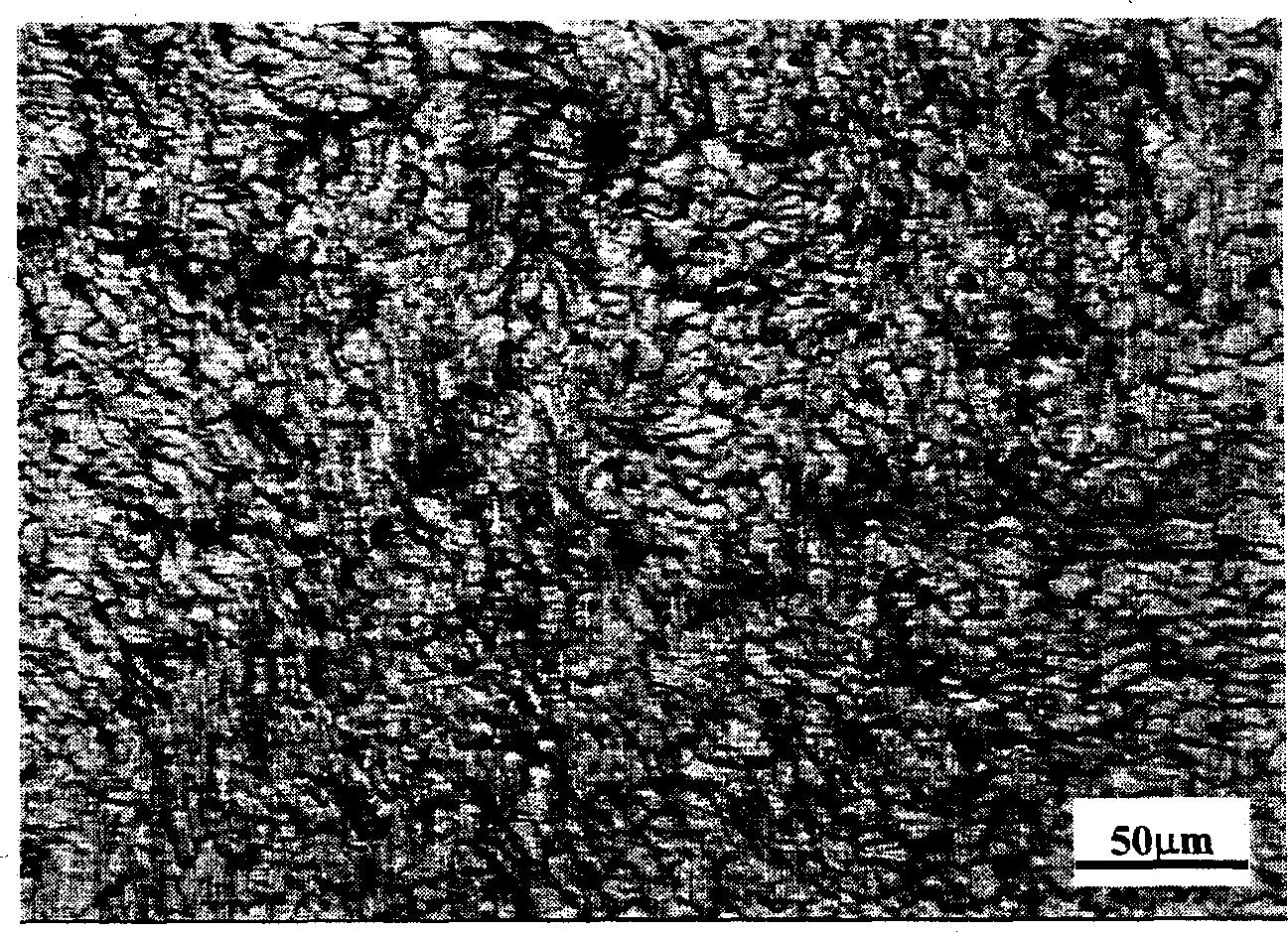

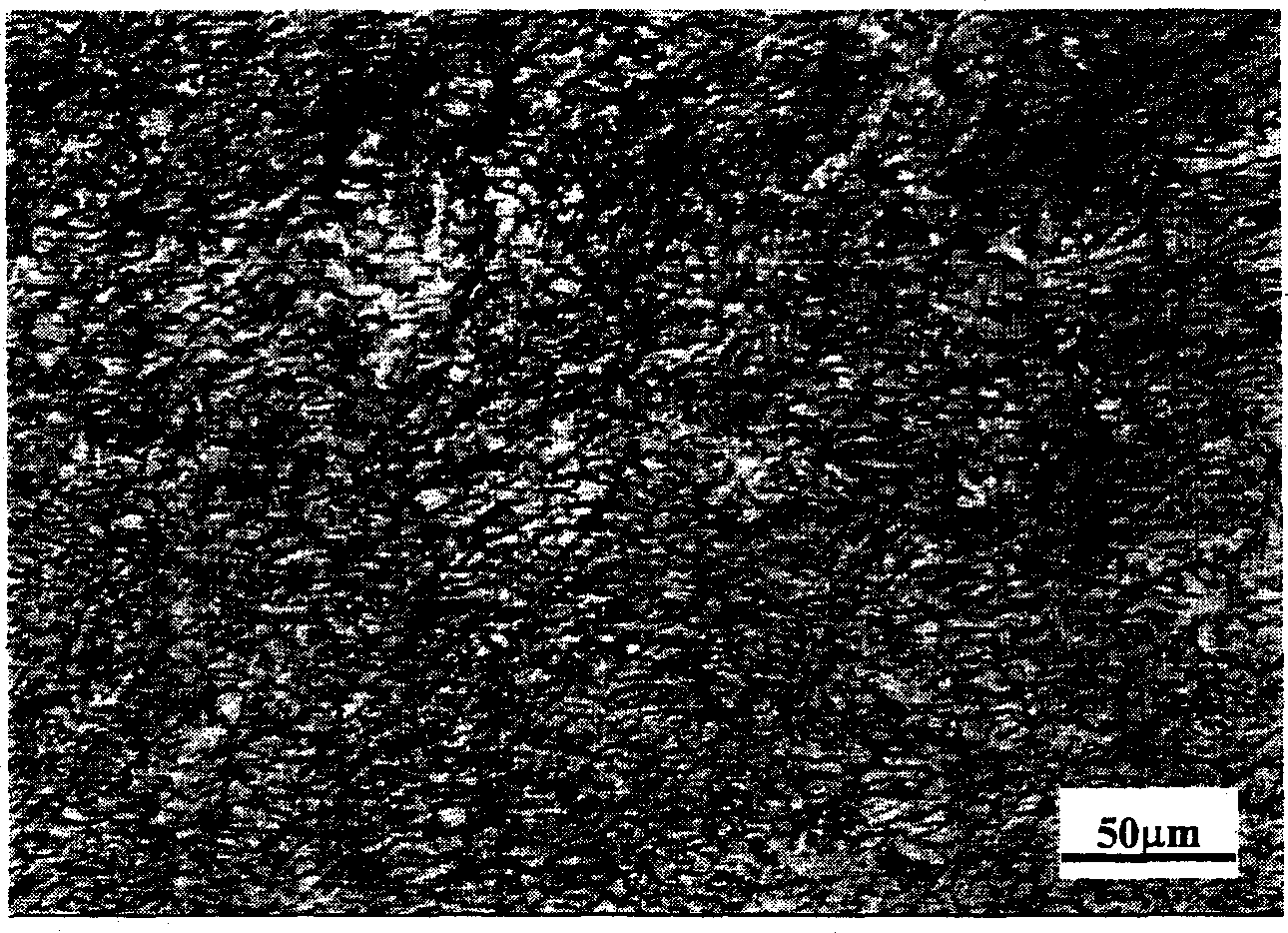

[0049] figure 1 It is the metallographic structure of ordinary Ti44Ni47Nb9 ternary shape memory alloy, the white area is the matrix phase, and the black area is the eutectic area composed of the matrix phase and the niobium-ric...

Embodiment 3~5

[0051] The alloy was prepared by the method described in Example 2, and its mechanical properties at room temperature were measured. The results are shown in Table 4.

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com