Swelling type combustion inhibitor and its synthesis method

An intumescent flame retardant and a synthesis method technology, applied in the direction of fire-resistant coatings, etc., can solve the problems of easy water absorption, high cost, poor stability, etc., and achieve easy industrialization, reduce production costs, and improve water resistance and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

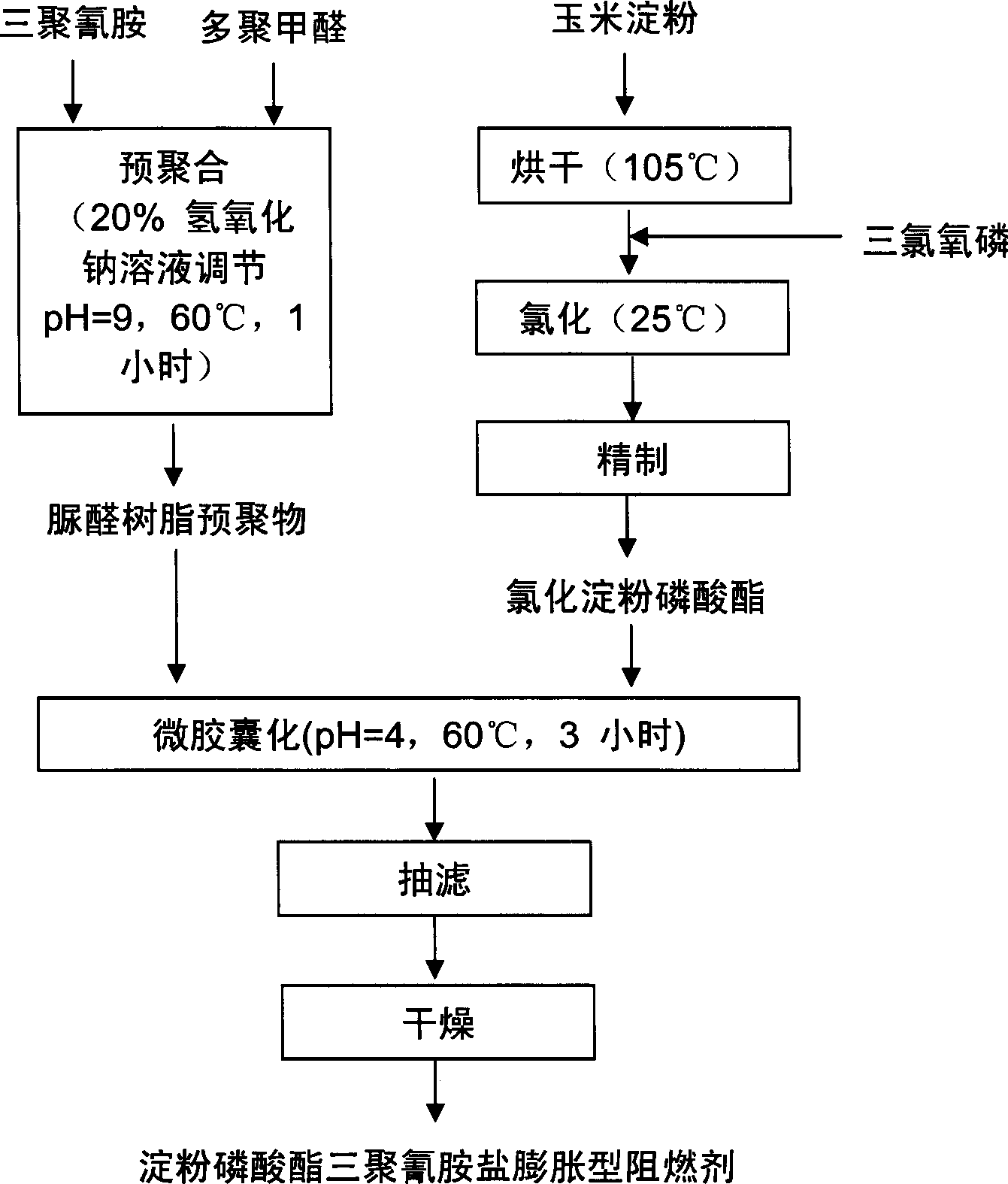

[0019] Embodiment one: see attached figure 1 As shown, add 5 grams of starch and 10 grams of phosphorus oxychloride (about 10 milliliters) in a 100 milliliter three-necked bottle equipped with an exhaust gas absorption device according to a mass ratio of 1:2, under nitrogen protection, and stir evenly. The reaction was carried out at 25°C for 12 hours. After the reaction is finished, the product is vacuum-dried to obtain chlorinated starch phosphate. The content of phosphorus is detected, so as to deduce the molar content of chlorine. The yield was 96%.

[0020] Add 2.1 grams of melamine and 0.9 grams of paraformaldehyde into a 100 ml three-necked bottle, add 20 ml of deionized water, adjust the pH of the solution to about 9.0 with 20% sodium hydroxide solution, and then slowly heat to 80°C until the solution becomes After clearing, continue to keep warm for 15 minutes to obtain a melamine-formaldehyde prepolymer. Then take 9 grams of chlorinated starch phosphate and add i...

Embodiment 2

[0021] Embodiment 2: Add 10 grams of starch and 20 milliliters of phosphorus oxychloride into a 100 milliliter three-necked bottle equipped with a tail gas absorbing device according to a mass ratio of 1:2, protect with nitrogen, and stir evenly. The reaction was carried out at 25°C for 12 hours. After the reaction is finished, the product is vacuum-dried to obtain chlorinated starch phosphate. The content of phosphorus is detected, so as to deduce the molar content of chlorine. The yield is 93%.

[0022] Add 4.2 grams of melamine and 1.8 grams of paraformaldehyde into a 100 ml three-necked bottle, add 40 ml of deionized water, adjust the pH of the solution to about 9.0 with 20% sodium hydroxide solution, and then slowly heat to 80°C until the solution becomes After clearing, continue to keep warm for 15 minutes to obtain a melamine-formaldehyde prepolymer. Then take 18 grams of chlorinated starch phosphate and add it to the prepolymer, add 8 milliliters of Tween 80, stir v...

Embodiment 3

[0023] Embodiment 3: Add 20 grams of starch and 50 milliliters of phosphorus oxychloride into a 250 milliliter three-necked bottle equipped with an exhaust gas absorption device according to a mass ratio of 1:2.5, and stir evenly under nitrogen protection. Afterwards, the reaction was incubated at 25° C. for 14 hours. After the reaction is finished, the product is vacuum-dried to obtain chlorinated starch phosphate. The yield was 89%.

[0024] Add 9.0 grams of melamine and 4 grams of paraformaldehyde into a 250 ml three-necked bottle, add 90 ml of deionized water, adjust the pH of the solution to about 9.0 with 20% sodium hydroxide solution, and then slowly heat to 85°C until the solution becomes After clearing, continue to keep warm for 20 minutes to obtain a melamine-formaldehyde prepolymer. Finally, weigh 30 grams of chlorinated starch phosphate and add it to the prepolymer, add 12 milliliters of Tween 80, stir vigorously at room temperature for 10 minutes, then raise the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com