Lithium ion battery anode material and producing method thereof

A technology for lithium ion battery and positive electrode material, which is applied in the field of positive electrode material for lithium ion battery and its preparation, can solve the problems such as the deterioration of pulping and coating processing performance of the positive electrode material, the reduction of the specific capacity of the positive electrode material, and the poor conductivity, etc. Electrochemical performance, maintenance of processability, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

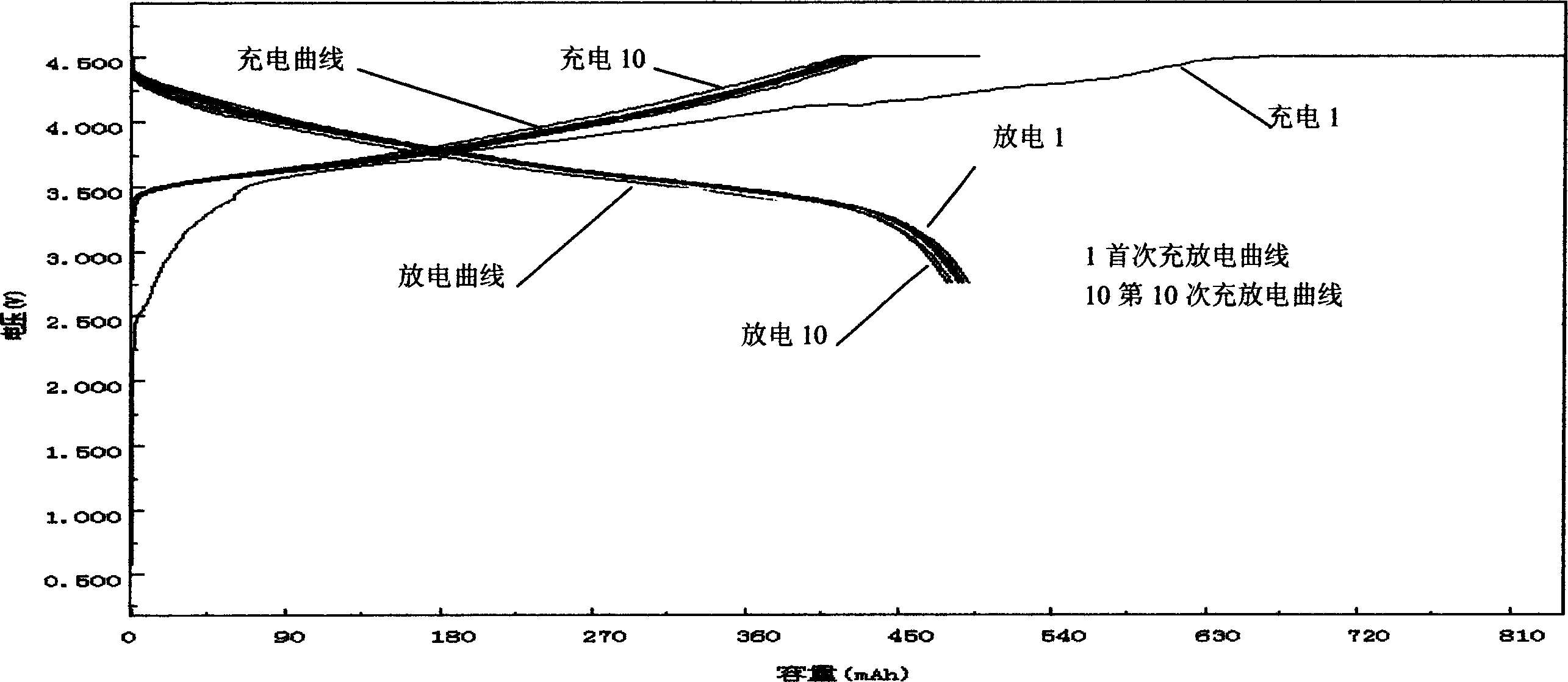

[0019]Add 5 liters of ammonia water with a concentration of 0.4mol / L (mol / liter) into a 40-liter reactor. After the temperature of the kettle reaches the predetermined temperature of 60°C, start the impeller agitator to make its speed 400RPM. Calculate the pH value of ammonia water. Then, a mixed salt solution with a concentration of 2.0mol / L is introduced from the first high-level tank through a rotameter, and the salt solution is composed of an aqueous solution of nickel sulfate, cobalt sulfate and aluminum sulfate in a fixed ratio, wherein the atomic ratio of each metal element salt It is Ni: Co: Al=0.75: 0.1: 0.15. At the same time, NaOH and ammonia water containing 4.0 mol / L and 0.8 mol / L are fed through another rotameter from the second high position tank in parallel flow lye, so that the pH value of the mixture in the kettle is always maintained at 11.00±0.10. After the addition of the ingredients was completed, the stirring was continued for 2 hours. Then the resulti...

Embodiment 2

[0023] The precursor mixed hydroxide is prepared in the same way as in Example 1, except that the precursor mixed hydroxide in this example contains the third doping element Mn, and its composition is Ni 0.75 co 0.10 Al 0.10 mn 0.05 (OH) 2 , and during co-precipitation, the pH value was 11.5±0.05. Also according to the method of Example 1, mix the precursor mixed hydroxide with LiOH·H 2 O is mixed and calcined together. The difference is that the molar ratio of the ingredients in this example is: 1:1.07, and the resulting product LiNi 0.75 co 0.10 Al 0.10 mn 0.05 o 2 Also black powder.

[0024] In this example, the coating process of the positive electrode material substrate particles is as follows:

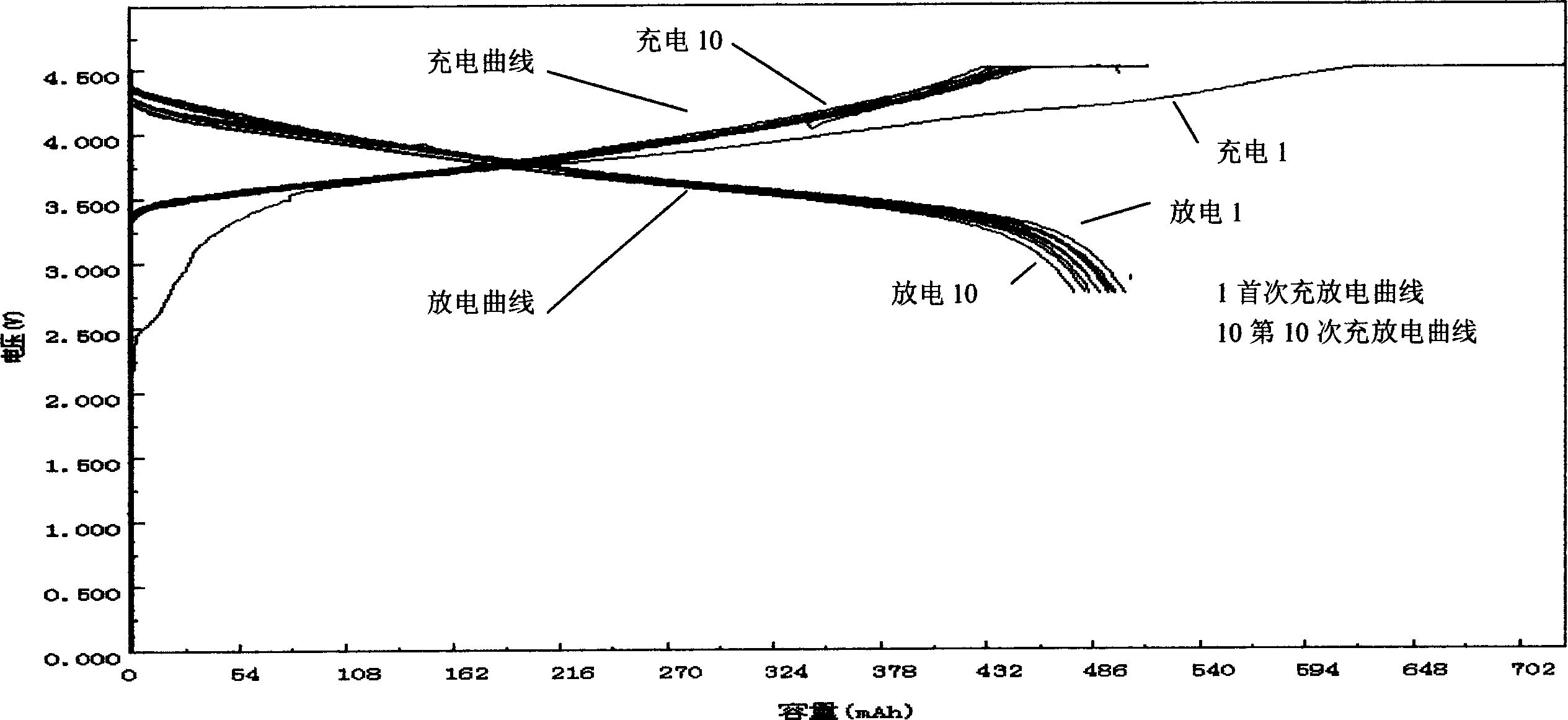

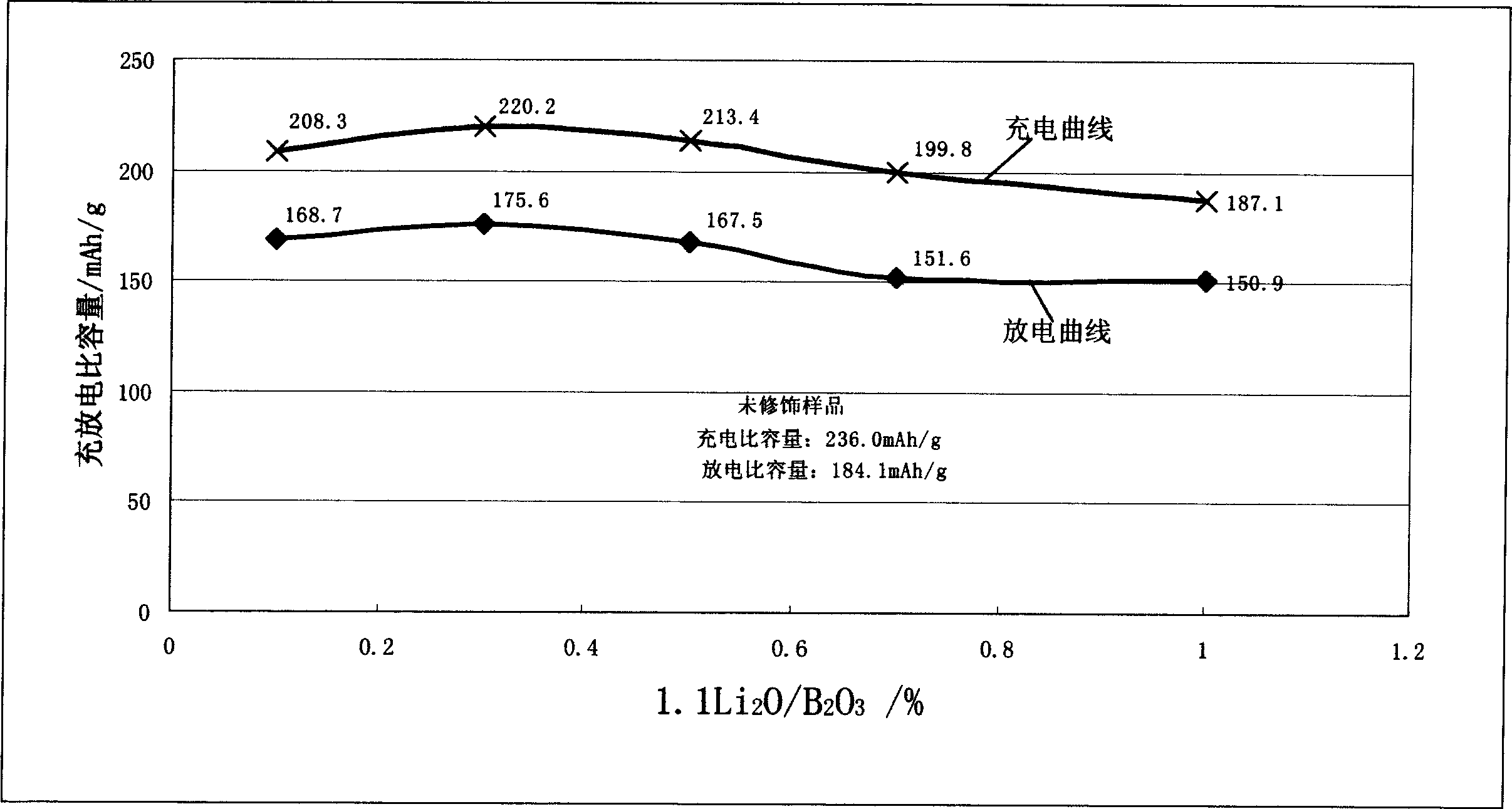

[0025] First, the preparation of LiOH·H 2 O / H 3 BO 3 =1.1 / 1 (molar ratio) of 2% solution (abbreviated as liquid A), the preparation concentration is 2% polyethylene oxide (PEO) solution (abbreviated as liquid B) with a molecular weight of 250,000. Then, 100 g of dri...

Embodiment 3

[0028] Synthesize LiNi by the method for embodiment 2 0.75 co 0.10 Al 0.10 mn 0.05 o 2 Positive electrode material base material. The difference is that in this example, LiF·Li 3 PO 4 Fast ion glass instead of Li 2 O·B 2 o 3 as coating material. The synergistic coated polymer solution uses 2% PVA solution with a molecular weight of 100,000, and the coated positive electrode active material has good processability and electrochemical performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com