Biological desulfurizer and dry desulfurizer treating method for high concentration hydrogen sulfide gas

A technology of biological desulfurization and desulfurizer, applied in the direction of chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of increased operating costs, secondary pollution of the surrounding environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

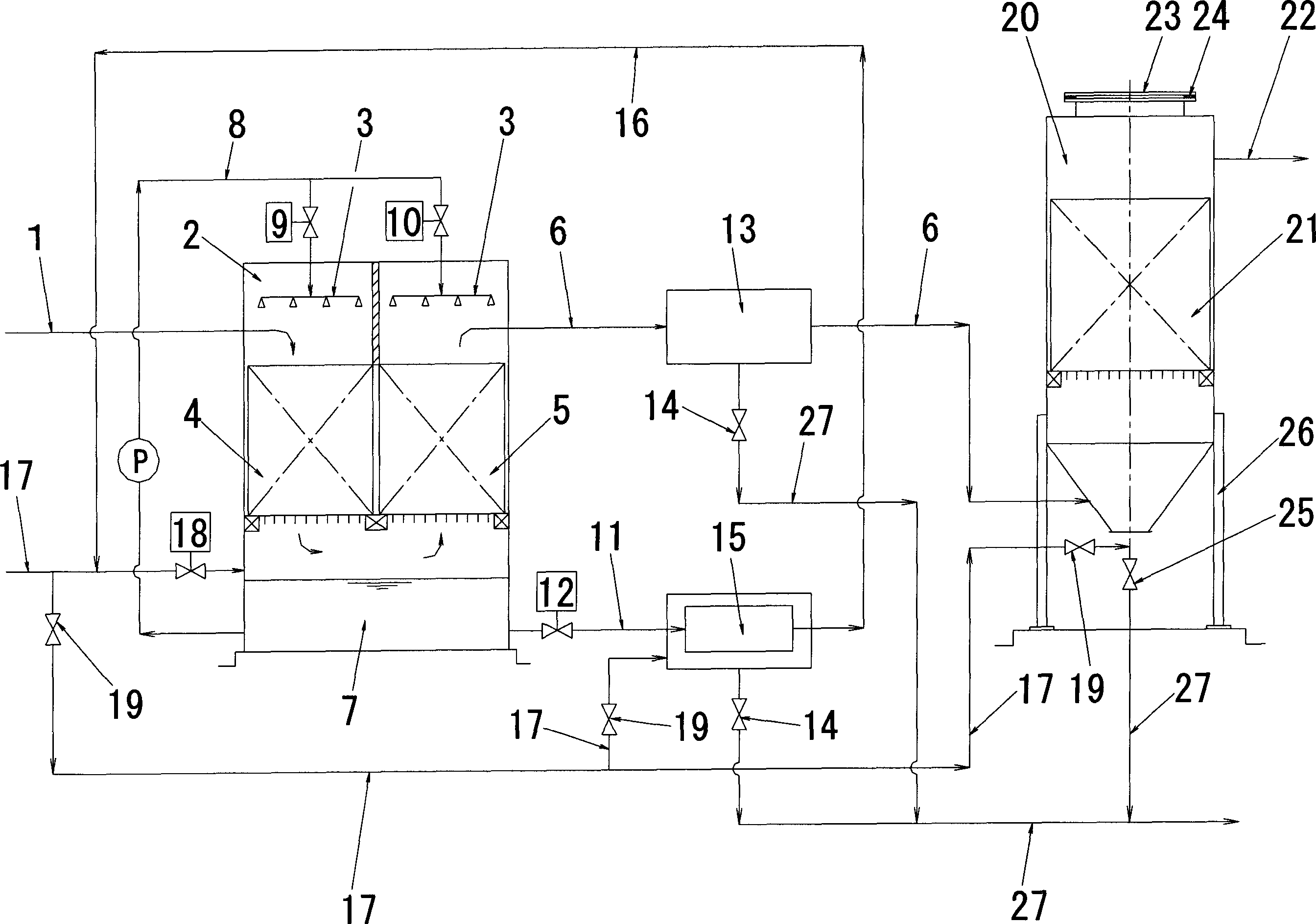

[0015] The present invention is further described below in conjunction with embodiment and accompanying drawing.

[0016] In the embodiment shown in the figure, when the waste gas containing high-concentration hydrogen sulfide and other organic components in the digested gas flows into the shell 2 of the biological desulfurizer through the digested gas inlet pipe 1, the intermediate partition is set, forcibly It flows from top to bottom into the first-stage biological desulfurization device 4 equipped with a microporous octagonal ceramic carrier (hereinafter referred to as: carrier), and then flows into the carrier-equipped In the second-stage biological desulfurization device 5, the activated treatment water that has been biologically aerated and dissolved in a large amount of air is used, and the water inlet pipeline 8 connected to the water pump disposed outside the biological desulfurizer housing 2 and the circulating treatment water are used. Quantitative (1) electric con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com