Abrasion-resistant bearing of motor type fuel pump

A fuel pump, wear resistance technology, applied in the direction of bearings, shafts and bearings, bearing components, etc., can solve the problems of rapid wear, accelerated wear, and no wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

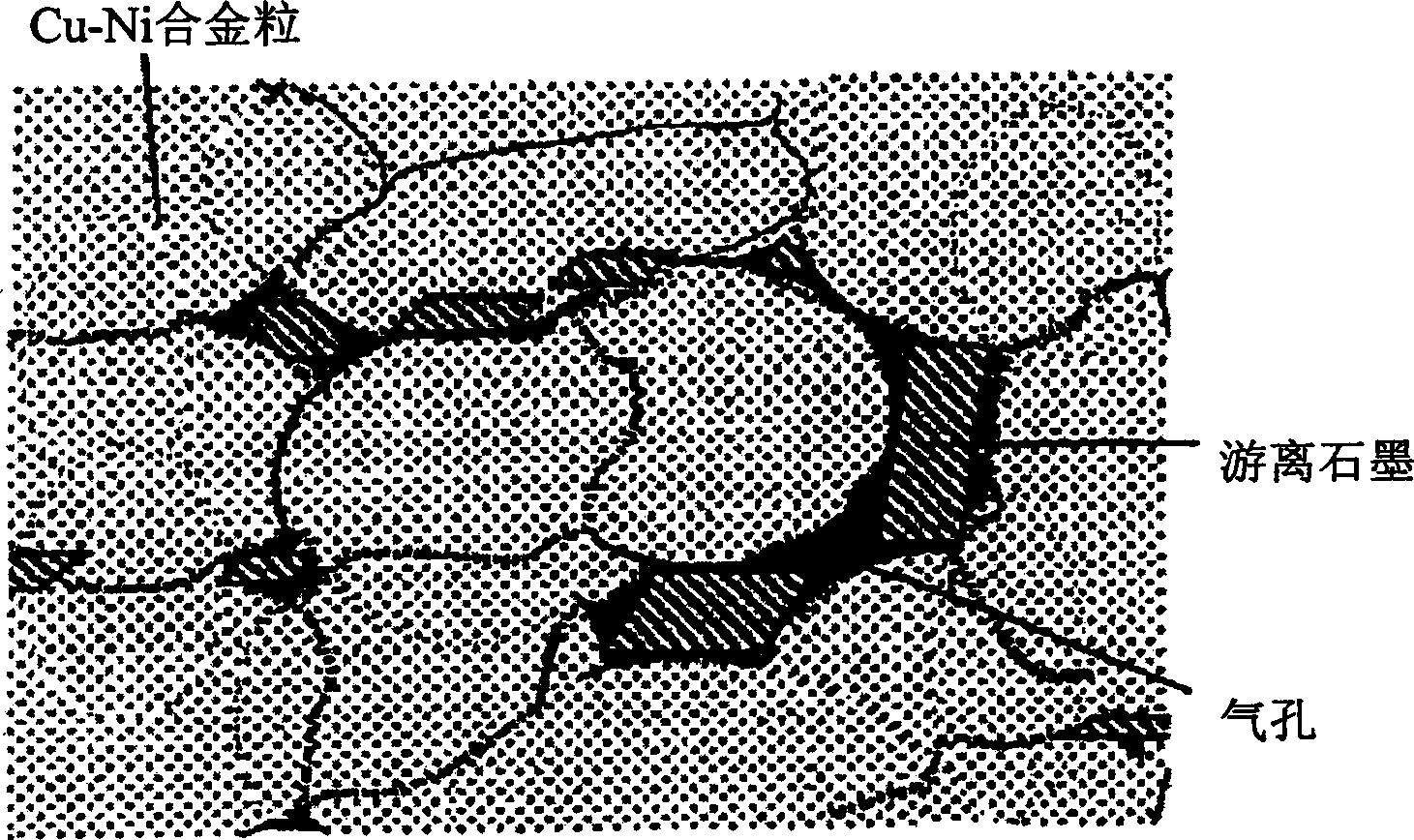

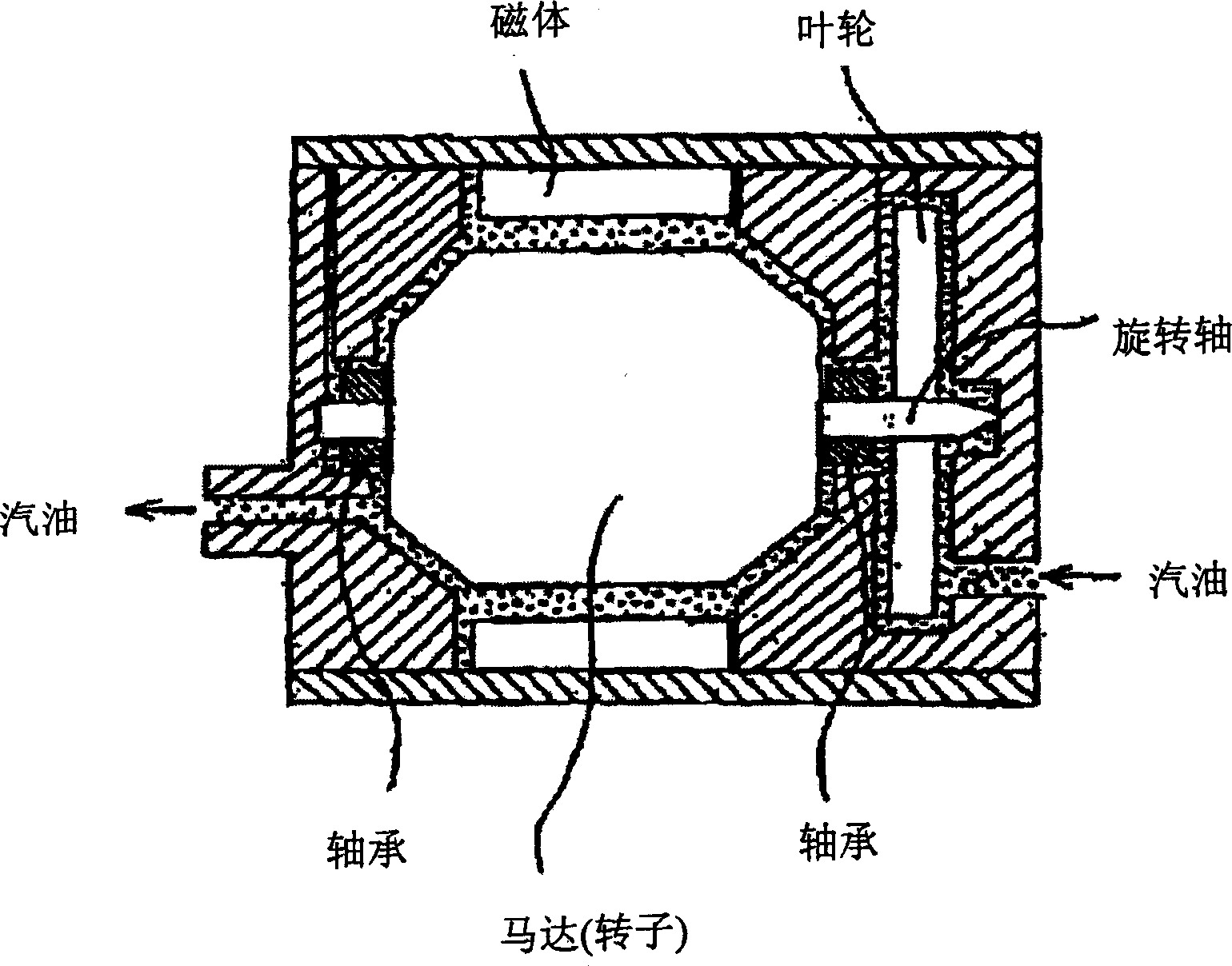

[0023] The bearing of the motor fuel pump of the present invention will be described more specifically based on an embodiment. As raw material powders, Cu-Ni alloy (Ni content ratios are shown in Tables 1 and 2) powders, Cu-P alloys (similarly, P content The ratios are shown in Tables 1 and 2) powder, graphite powder, Sn powder, Co powder, Fe powder, and Cu powder. These raw material powders are blended into the compounding compositions shown in Tables 1 and 2, and 1% of stearic acid is added. , after mixing for 20 minutes by a V-type mixer, stamping and forming a green compact with a predetermined pressure in the range of 400-500 MPa, the green compact is sintered at 870°C for 40 minutes in an ammonia decomposition gas atmosphere , In addition, finally, the sizing treatment is carried out at a predetermined pressure in the range of 400-500MPa, so as to manufacture Cu-Ni-based sintered alloys or Cu-based sintered alloys with porosities shown in Tables 1 and 2, respectively. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com