Burning furnace for treating unsyn dimethyl hydrazonium or/and dinitrogen tetra oxide and its application method

A technology of dinitrogen tetroxide and unsymmetrical dimethyl hydrazine, applied in the field of combustion furnaces, can solve the problems of death, huge equipment, deactivation, etc., and achieve the effects of uniform flame distribution, complete functions, and safe combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The treatment product is dinitrogen tetroxide waste gas 100wt%, and the fuel is kerosene:

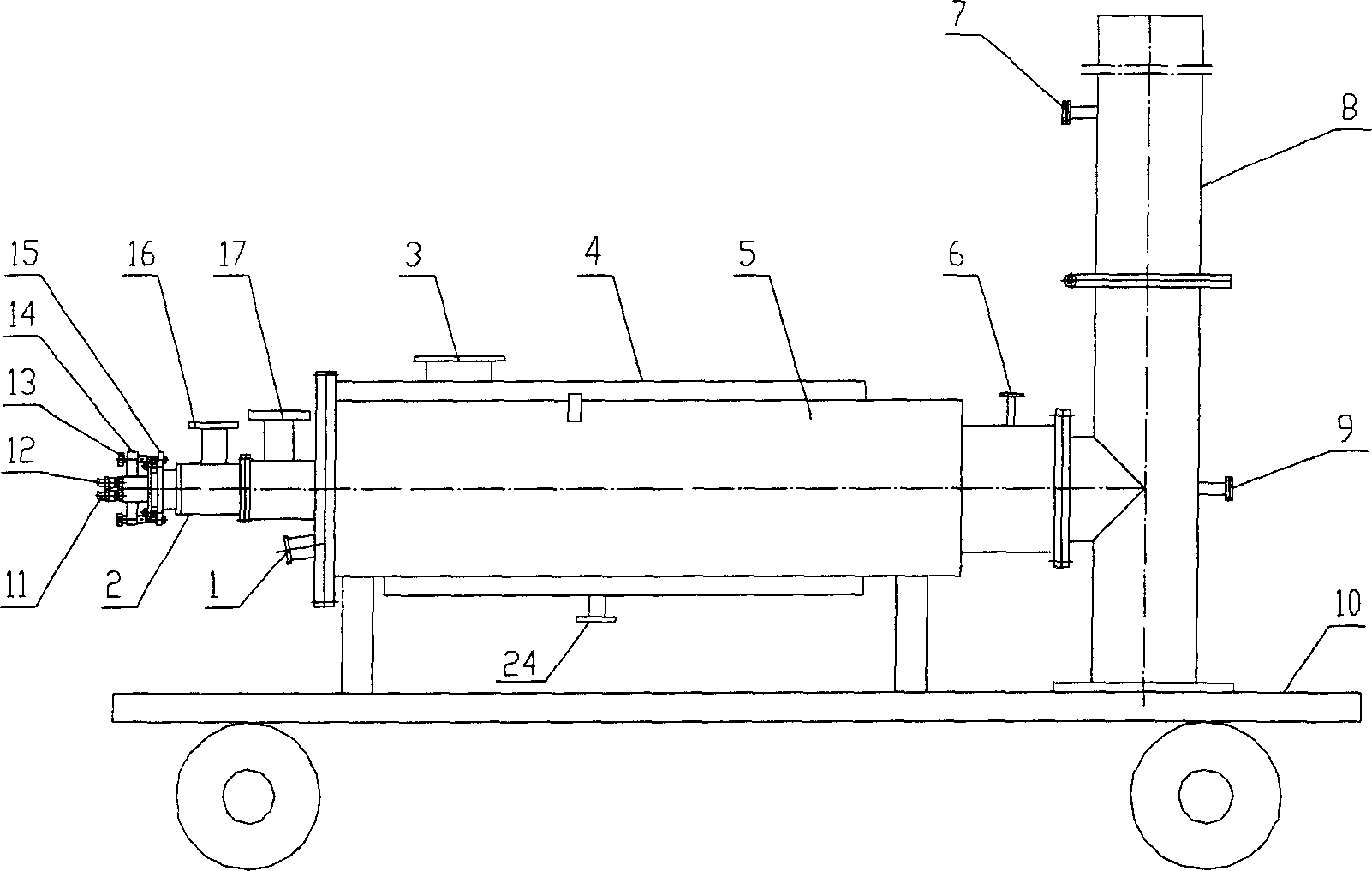

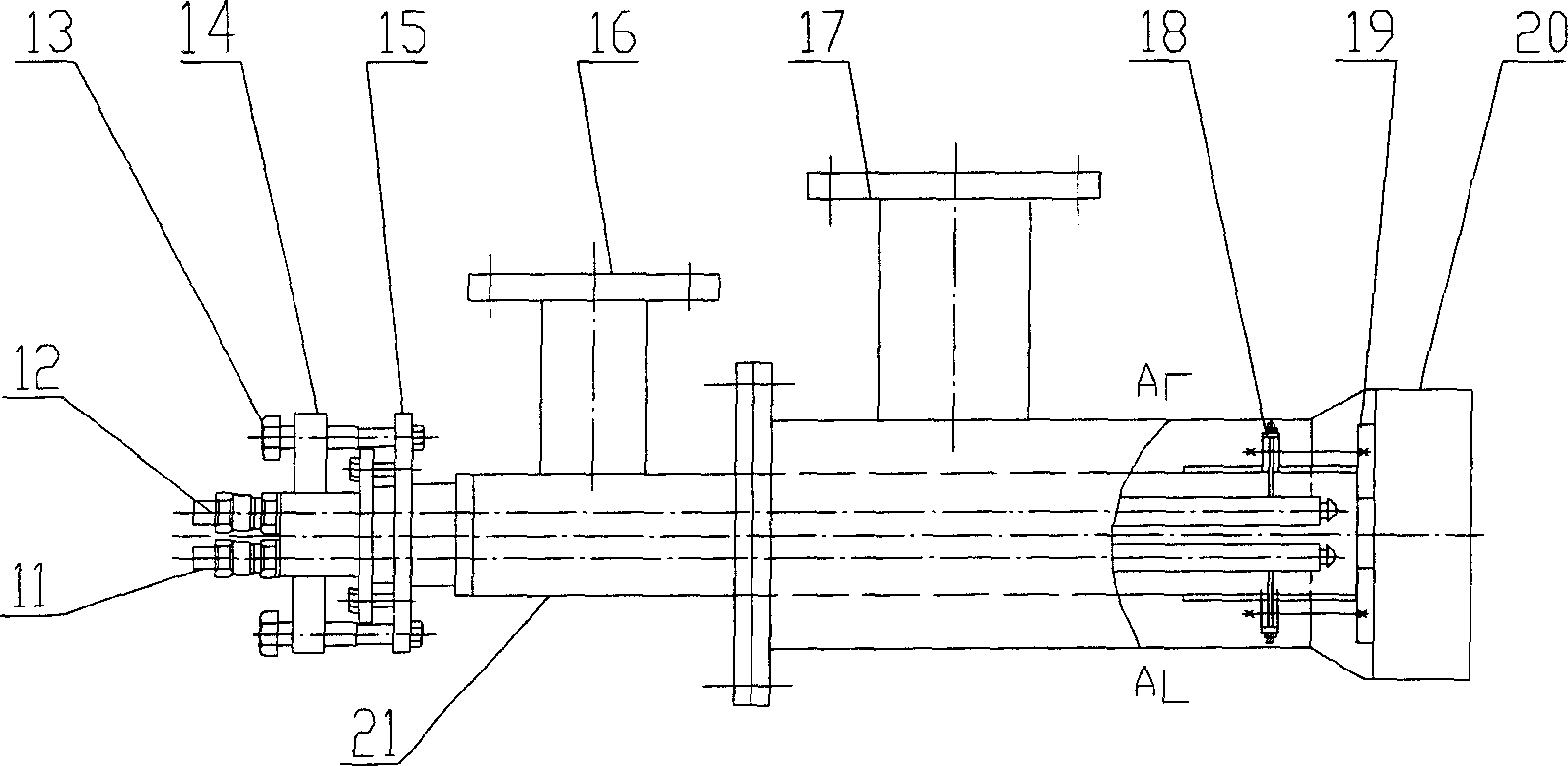

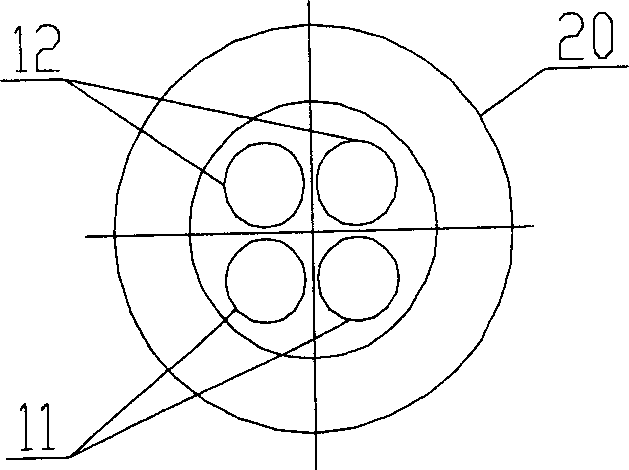

[0040] During the processing operation, the air enters the furnace from the primary air inlet 17 and the secondary air inlet 3, the primary air coefficient is 0.96, the total air coefficient is controlled at 2.5, the ignition button is activated, the ignition port 1 is ignited, and the fuel nozzle 11 is sprayed. Combustion, the furnace starts to heat up. When the temperature of the temperature measuring port 6 of the furnace body reaches 600 ° C, dinitrogen tetroxide is introduced into the furnace from the processing gas inlet 16 and burns together with the fuel under the action of air, and the flame combustion is observed through the fire viewing hole. Turn the adjustment screw 13 appropriately to adjust the gap between the distribution plate 19 and the restrictor cylinder 20 to make the air distribution reasonable. At this time, open the secondary combustion nozzle in the middle...

Embodiment 2

[0042] Other conditions are the same as in Example 1, the concentration of the treated substance is changed to 80% dinitrogen tetroxide, the primary air coefficient is adjusted to be 0.74, the total air coefficient is 2.7, and the nitrogen dioxide content in the tail gas is 650ppm.

Embodiment 3

[0044] Other conditions are the same as embodiment 1, change the treatment substance concentration into 20% dinitrogen tetroxide, use aviation kerosene instead of fuel oil, adjust the primary air factor to be 0.80, and the total air factor is 2.9, sampling analysis, nitrogen dioxide content in the tail gas is 620ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com