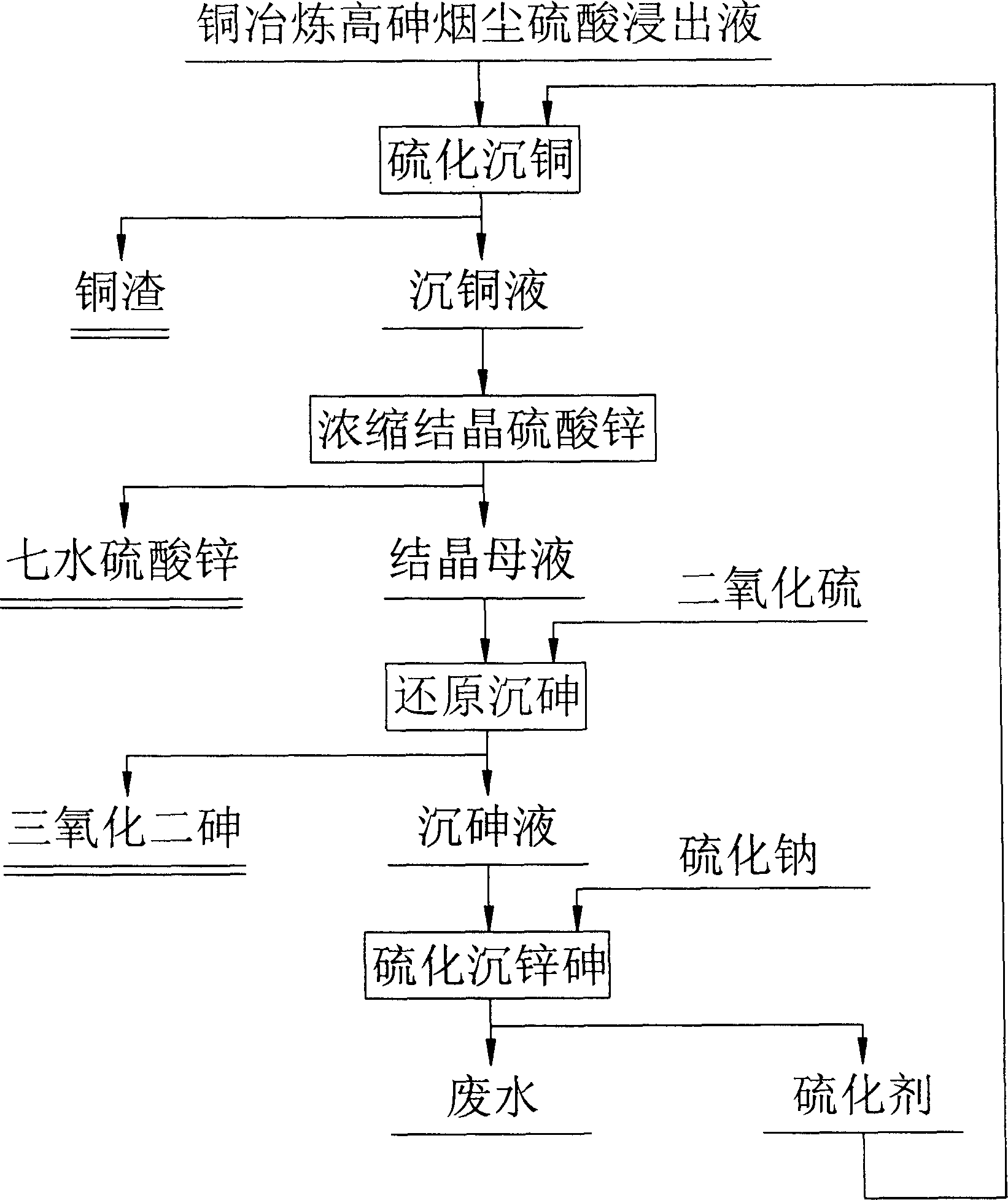

Method for separating copper, arsenic and zinc from copper-smelting high-arsenic flue dust sulphuric acid leach liquor

An arsenic fume, copper smelting technology, applied in the direction of improving process efficiency, can solve the problems of secondary pollution, failure to effectively control arsenic pollution, etc., achieve high recovery rate, great environmental and social significance, and control arsenic pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0008] Composition of sulfuric acid leaching solution (g / L) of a copper smelting high-arsenic dust: Cu 6, As 10, Zn 18, H 2 SO 4 5;

[0009] Process as follows:

[0010] 1) Copper sulfide precipitation: In the stirring state of the above leaching solution, heat the steam to 50-60°C, add a sulfurizing agent of a mixture of zinc sulfide and arsenic sulfide, and carry out the copper precipitation reaction. When the reaction reaches the end, stop adding the mixture of zinc sulfide and arsenic sulfide. Plate and frame filter press, the steam is heated to above 85°C before the filter press to improve the filtration performance. Judgment method for the end point of copper sulfide precipitation: take a small amount of solution and filter it, and the filtrate has no blue color, which is the end point. The first required copper sinking vulcanizing agent reacts with zinc sulfate heptahydrate and sodium sulfide. The mass ratio of zinc sulfate heptahydrate and sodium sulfide is 2:1. Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com