Sinter-bonded direct pin connections for inert anodes

An inert anode and inert electrode technology, applied in the field of low-resistance electrical connection, can solve the problems of unsuitable assembly parts, inert material cracking and electrical connection resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

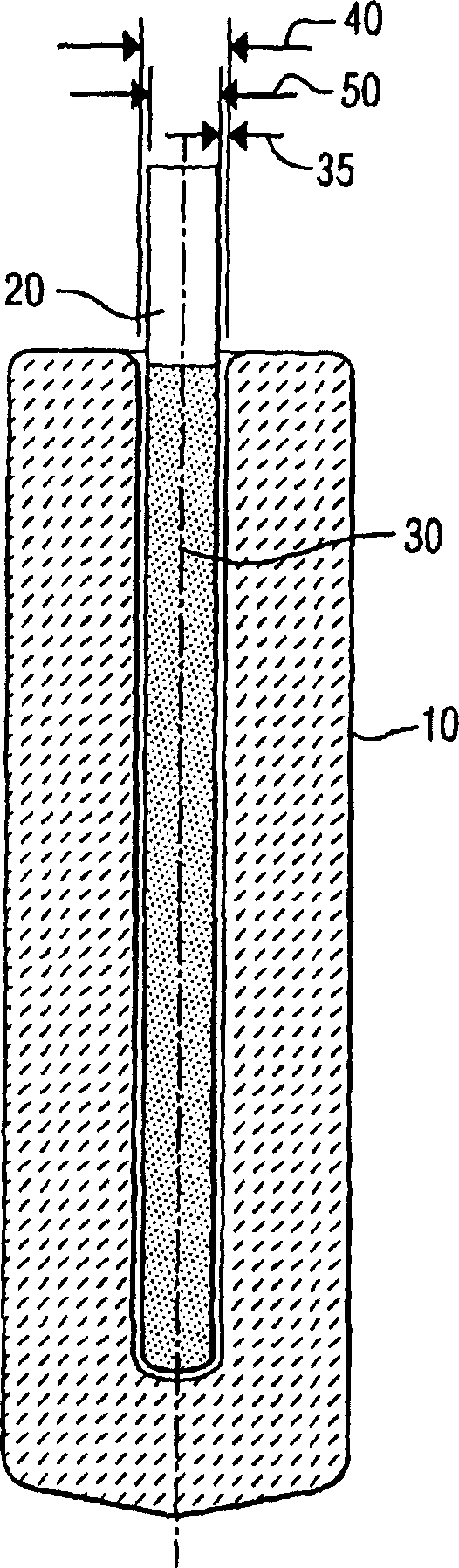

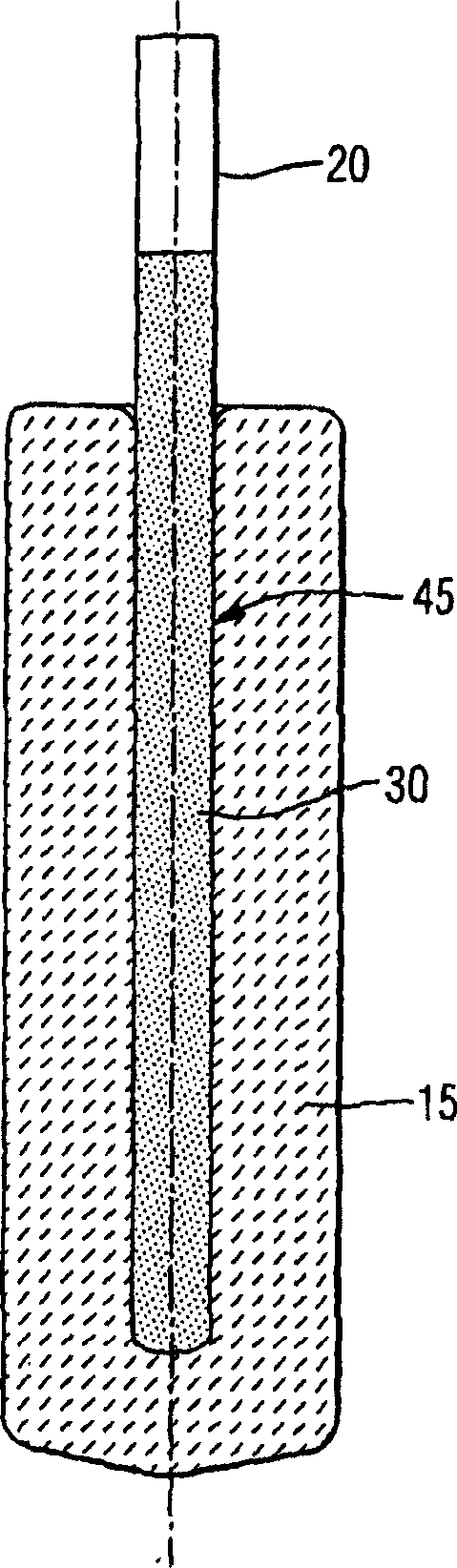

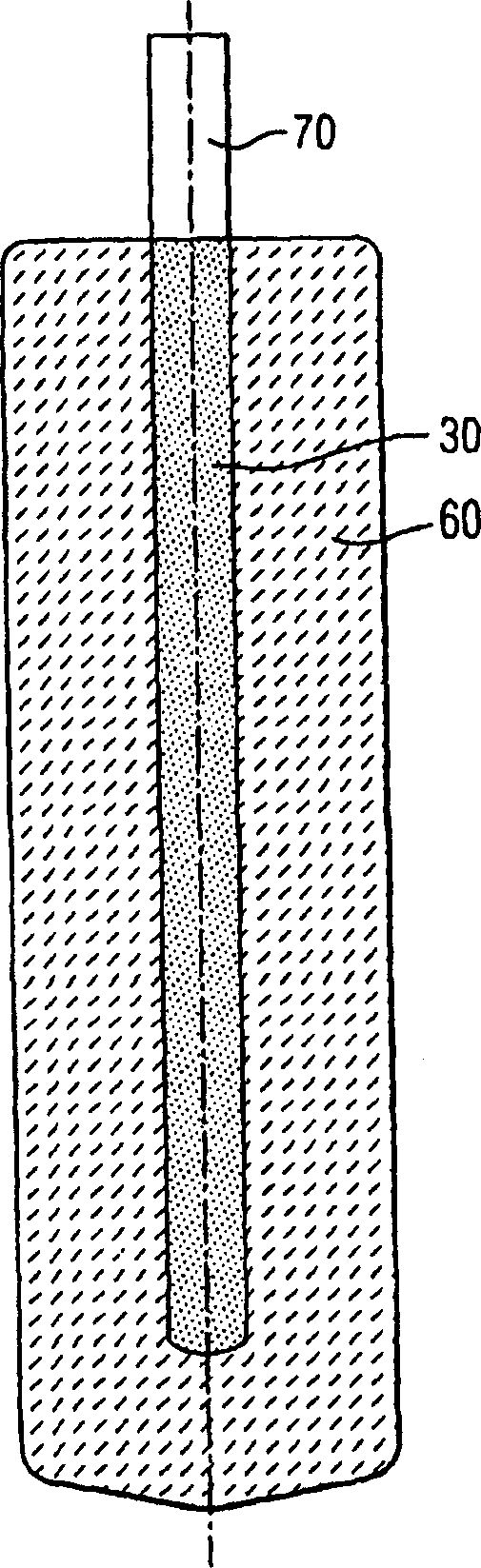

[0029] An electrode assembly was prepared using a hollow inert anode, a metallic conductor comprising Inconel 600, and a coating on the conductor made of a copper-nickel alloy. The anode was isostatically pressed from powder with a hollow opening 0.813 inches (2.06 cm) in diameter. The porosity of the anode after pressing is about 40% by volume. The pins were 0.75 inches (1.9 cm) in diameter and the surface additive coating was flame sprayed to a thickness of 0.030 inches (0.076 cm) around the pins. The composition of the coating is 67.8% by weight of copper, 30.6% by weight of nickel and a small amount of iron, manganese, titanium and other impurities. In an argon atmosphere, the anode is sintered at 1250°C until a true density is obtained, with a porosity of about 1% to 5% by volume. The co-contraction allows the sintered anode material to contact the pin and coating and form a continuous coherent electrical contact at the interface. The bond is strong enough to act as a ...

example 2

[0032] A series of 24 anodes were fabricated and tested in a statistically designed experimental matrix. Each electrode assembly was prepared using a hollow inert anode, a metal conductor, and an additive coating on the conductor. The conductors include copper-nickel alloys. The anode is isostatically pressed from powder with hollow openings of different diameters. The composition of the coating is 67.8% by weight of copper, 30.6% by weight of nickel and the balance of iron, manganese, titanium and other impurities. In an argon atmosphere, the anode is sintered at 1250°C until a true density is obtained, with a porosity of about 1% to 5% by volume. Co-shrinkage allows the sintered anode material to contact the pins and coating and form a continuous coherent electrical contact at their interface. The bond is strong enough to act as a mechanical support. The final anode dimensions were 6 inches (15.24 cm) long and 3 inches (7.62 cm) in diameter with a hemispherical base.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com