New strain for producing penicillium chrysogenum and ferment for preparing penicillin by using the strain

A technology for producing Penicillium chrysogenum and Vitiligo, applied in fermentation, application, fungi, etc., can solve problems such as troublesome work and failure to improve penicillin production capacity, so as to improve efficiency, increase cell production and penicillin synthesis, and increase production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

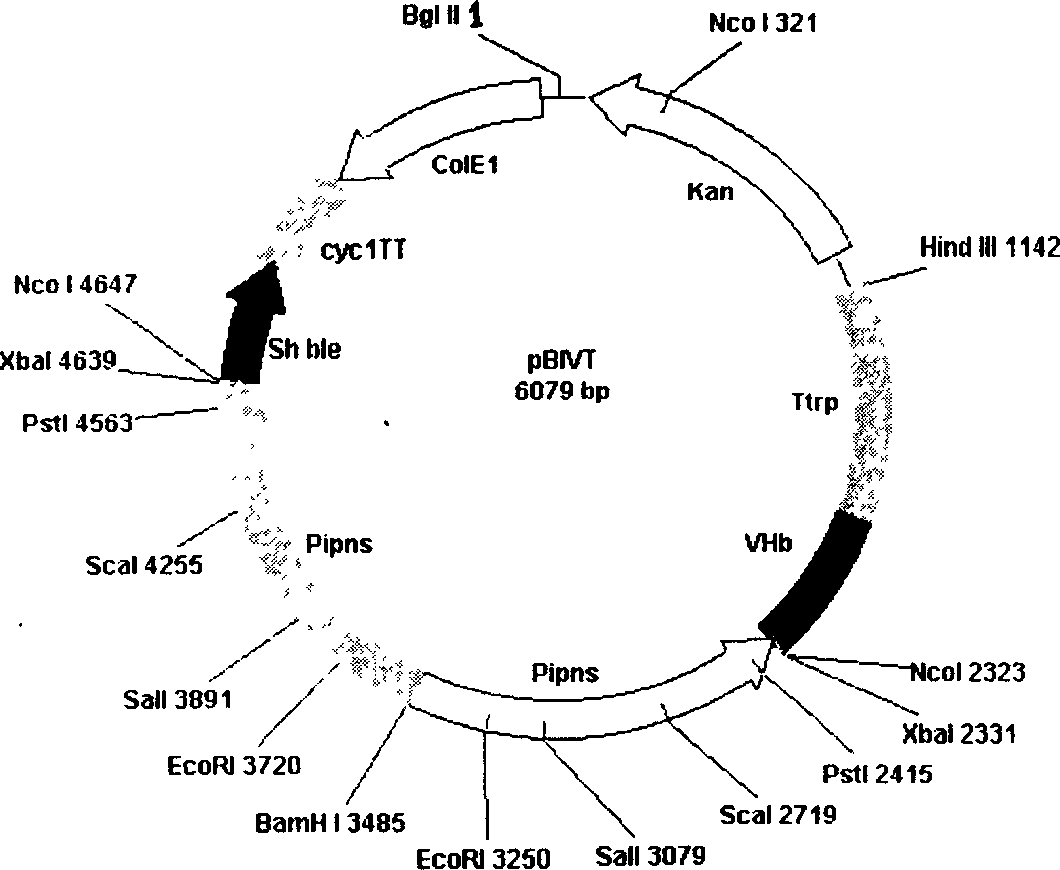

[0017] Embodiment 1 gene cloning and the construction of gene transformation vector

[0018] The transformation vector pPIPKA of Penicillium chrysogenum was constructed according to the description of the Chinese invention patent application number 200410012139.4. The plasmid vector of pDH25 was purchased from Fungal Genetics Stock Center, University of Kansas Medical Center. The host bacteria Penicillium chrysogenum ATCC 28953 for gene transformation was purchased from the American Type Culture Collection. pGEM-T is a product of Promega, USA.

[0019] Molecular cloning techniques used in the present invention include separation and purification of DNA, DNA synthesis, polymerase chain reaction (PCR), restriction endonuclease digestion of DNA, connection of DNA, Escherichia coli transformation screening, sequence analysis, etc. is well known in the art and is fully described in Molecular Cloning, a laboratory manual by Sambrook et al.

[0020] According to the Oxygen Binding...

Embodiment 2

[0024] Embodiment 2 Penicillium chrysogenum transformation and positive clone screening

[0025] 1. Culture of microorganisms

[0026] Penicillium chrysogenum NCPC10086 was grown in YPD medium (1% yeast extract, 2% peptone, 2% glucose). The chromosomal DNA of this strain was used to isolate the Pipns sequence. At the same time, the bacterium is also used as a host for cefE gene transformation. YPD medium is also used for the culture of protoplasts.

[0027] 2. Transformation of Penicillium chrysogenum

[0028] Using the Ca-PEG-mediated protoplast transformation method, the pBIVT vector was transformed into Penicillium chrysogenum according to the method of Wang Fuqiang et al. (Acta Mycophyta Sinica, 23:66-72, 2004). Positive clones were screened on YPD selective medium containing bleomycin.

[0029] 3. Detection of transformants

[0030] P. chrysogenum transformants were purified by subculturing twice on selective medium (1% yeast extract, 2% peptone, 2% glucose, 2ug / ml ...

Embodiment 3

[0031] Embodiment 3 shaking flask fermentation and target product detection

[0032] Penicillium chrysogenum ATCC 28953 was transformed with the transgene vector pBIVT described in Example 1, and 272 positive clones were obtained. Transgenic positive strains were used in 2×10 6 Conidia / ml inoculated seed medium (g / l): glucose, 30; lactose, 10; cotton cake powder, 10; yeast powder, 10; corn steep liquor, 10; (NH 4 ) 2 SO 4 , 2; KH 2 PO 4 , 1; CaCO 3 , 5. pH 5.8. 26°C, 48 hours. Seed culture was inoculated with 5% inoculum of fermentation medium (g / l): lactose, 120; cotton cake powder, 30; corn steep liquor, 20; (NH 4 ) 2 SO 4 , 5; KH 2 PO 4 ,1;K 2 SO 4 , 5; CaCO 3 , 10; pH 6.5, cultured at 26°C for 144 hours.

[0033] After the fermentation, the fermentation liquid was centrifuged with a centrifugal force of 8000 g for 15 minutes to remove the mycelium, and the fermentation supernatant was obtained for detection of penicillin yield. Assays were performed accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com